S600 Aluminum Coil Price for Wooden Grain Coating Aluminium Coil AA3003 for Roller Shutter Doors

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Wooden Grain Coating Aluminium Coil AA3003 for Roller Shutter Doors

characteristics | Application |

1) Super peeling strength | 1) Building exterior curtain walls |

2) Excellent surface flatness and smoothness | 2) Decoration and renovation additions for old buildings |

3) Superior weather, corrosion, pollutant resistance | 3) Decoration of interior walls, ceilings, bathrooms, kitchens and balconies |

4) Even coating, various colors | 4) Shop door decorations |

5) Fireproof, excellent heat and sound insulation | 5) Advertisement board display platforms and signboards |

6) Superior impact resistance | 6) Wallboards and ceilings for tunnels |

7) Lightweight and easy to process | 7) Industrial materials, materials for vehicles and boats |

2. Application of Wooden Grain Coating Aluminium Coil AA3003 for Roller Shutter Doors

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels, column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Wooden Grain Coating Aluminium Coil AA3003 for Roller Shutter Doors

• Our goods quality is top, the surface is smooth, and every steel coil

• No Joint, No Bends, no spots, no roller marks.

• MTC will be provided with goods, third part inspection is acceptable, for example, SGS, BV. Etc

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

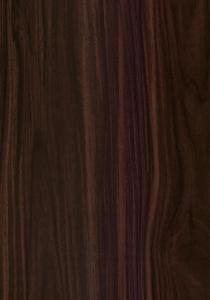

5. Image of Wooden Grain Coating Aluminium Coil AA3003 for Roller Shutter Doors

6. Package and shipping of Wooden Grain Coating Aluminium Coil AA3003 for Roller Shutter Doors

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: How are aluminum coils used in HVAC systems?

- The excellent heat transfer properties and durability of aluminum coils make them widely used in HVAC systems. These coils play a vital role in cooling by efficiently extracting heat from the air. In HVAC systems, you will typically find aluminum coils in the condenser and evaporator units. The condenser coil releases heat to the surroundings by transferring it to the outdoor air, while the evaporator coil absorbs heat from indoor air, cooling it down. Aluminum is the preferred material for these coils because of its high thermal conductivity, allowing for efficient heat transfer. The coils consist of thin aluminum fins attached to aluminum tubes. This design maximizes the coil's surface area, enabling better heat exchange between the refrigerant flowing through the tubes and the air passing over the fins. During the cooling process, the coil's refrigerant absorbs heat from the indoor air, transforming it into a gas. The heat is then transferred to the aluminum fins, where it dissipates into the surrounding air. Consequently, the air passing through the evaporator coil becomes cooler, creating a comfortable indoor environment. Similarly, in the condenser unit, the refrigerant releases heat to the outdoor air through the aluminum coils. This allows the refrigerant to return to its liquid state, ready to be cycled back to the evaporator coil for the cooling process to continue. Aluminum coils are also favored in HVAC systems due to their corrosion resistance, ensuring their longevity and reliability. They are lightweight, making installation and maintenance easier. Moreover, aluminum coils are recyclable, contributing to a more sustainable and eco-friendly HVAC system. In summary, aluminum coils are crucial components of HVAC systems, providing efficient heat transfer, durability, and corrosion resistance. Their use greatly contributes to the cooling and comfort of indoor spaces.

- Q: This question asks about the economic impact of aluminum coils, which are a key material in various industries.

- <p>Aluminum coils significantly impact the economy by driving growth in various sectors. They are vital in construction, automotive, aerospace, and packaging industries due to their lightweight, durability, and recyclability. The aluminum coil market stimulates manufacturing, job creation, and technological advancements. Additionally, their high demand supports the growth of the aluminum industry, influencing trade and contributing to GDP. The recycling of aluminum coils also reduces energy consumption and environmental impact, further benefiting the economy by promoting sustainable practices.</p>

- Q: I am looking to bake some Buffalo wings and am wondering if it's alright to bake them in an aluminum pan (disposable or otherwise). I will be brushing/basting the chicken in the sauce not 'drowning' the chicken in it. I have heard that acidic sauces like Tomato sauce (less acidic than wing sauce) should not be cooked in aluminum (stovetop pans bakeware) because of some chemical interaction, but I've seen those big foil pans full of pasta spaghetti sauce at wedding, etc. Is the whole acid/aluminum thing true or an old cooking myth?

- Cook the wings in the pan without the sauce so they will get good and crispy then put them in a covered bowl with the sauce and shake and serve.

- Q: How do aluminum coils compare to steel coils?

- Aluminum coils and steel coils have distinct characteristics that set them apart in terms of strength, weight, corrosion resistance, and cost. In terms of strength, steel coils generally have a higher tensile strength than aluminum coils. This means that steel coils can withstand greater stress and pressure without deforming or breaking. However, aluminum coils still possess sufficient strength for many applications and can be reinforced or designed for specific purposes. Weight is a significant factor when comparing aluminum and steel coils. Aluminum is a lightweight metal, approximately one-third the weight of steel. This lightweight property makes aluminum coils more advantageous in applications where weight reduction is critical, such as in transportation industries or aerospace. When it comes to corrosion resistance, aluminum coils outperform steel coils. Aluminum naturally forms a protective oxide layer that prevents further corrosion. On the other hand, steel is susceptible to rust and requires additional coating or treatment to enhance its corrosion resistance. This makes aluminum coils a preferred choice in coastal or humid environments where corrosion can be a major concern. Cost is another key consideration. Aluminum coils often have a higher initial cost than steel coils due to the higher cost of raw materials and manufacturing processes. However, the overall cost may vary depending on factors like transportation, maintenance, and lifespan. Aluminum coils tend to have lower maintenance costs and longer lifespans due to their corrosion resistance, which can offset the initial investment in the long run. In summary, aluminum coils offer several advantages over steel coils, including lower weight, superior corrosion resistance, and potential long-term cost savings. However, steel coils still boast higher tensile strength and may be the preferred choice in applications that require maximum strength or have a lower budget. Ultimately, the choice between aluminum and steel coils depends on the specific requirements and considerations of the intended application.

- Q: Can aluminum coils be used for roofing?

- Yes, aluminum coils can be used for roofing. Aluminum is a popular and commonly used material for roofing due to its durability, lightweight nature, and resistance to corrosion. It is often chosen for its ability to withstand harsh weather conditions and its long lifespan, making it a suitable option for various roofing applications.

- Q: Can aluminum coils be used for electrical applications?

- Yes, aluminum coils can be used for electrical applications. Aluminum is a widely used material in the electrical industry due to its excellent conductivity, lightweight properties, and corrosion resistance. Aluminum coils are commonly used in various electrical applications such as transformers, motors, generators, and coils for inductors and solenoids. They offer advantages such as high thermal conductivity and low eddy current losses, making them efficient in transferring and distributing electrical power. Additionally, aluminum coils are cost-effective compared to copper coils, making them a preferred choice for many electrical applications. However, it is important to note that aluminum has a lower electrical conductivity compared to copper, so the coil design and dimensions may need to be adjusted accordingly to ensure optimal performance.

- Q: Supposably water ozidies it what ever that means so how in the world do i clean an aluminum bike if i cant use water? i like to use water and soap on my carbon bike so what do i use on a aluminum?

- Aluminum will not rust. So water used sparingly in the right spots - away from vital bearings - shouldn't pose a problem. Just don't shoot a high pressure hose all over the place. I use a bunch of old clean rags Simple Green. Simple spray it on a rag - wipe the dirt off and follow up with another clean rag to wipe off any residue. Link below.

- Q: How do aluminum coils contribute to energy efficiency in buildings?

- The use of aluminum coils is crucial for improving energy efficiency in buildings. To begin with, aluminum is an extremely conductive material, allowing for efficient heat transfer. This characteristic is particularly important in HVAC systems, where aluminum coils are commonly employed. These coils aid in the transfer of heat between the indoor and outdoor units, enabling effective temperature regulation and decreasing energy usage. Furthermore, aluminum coils are lightweight, making them easier to handle and install. This not only saves time and labor costs but also reduces the overall weight of the HVAC system, resulting in lower energy requirements for operation. Additionally, the lightweight nature of aluminum coils allows for the creation of compact systems, conserving valuable space in buildings. Additionally, aluminum is highly resistant to corrosion, ensuring the long-lasting and durable nature of the coils. This resistance to corrosion is especially vital in areas with high humidity or exposure to harsh weather conditions. By maintaining their effectiveness over time, aluminum coils minimize the need for frequent replacements, thereby reducing energy consumption associated with the manufacturing and installation processes. Another significant advantage of aluminum coils is their recyclability. Aluminum is one of the most widely recycled materials globally, with a high recycling rate and minimal loss of quality during the process. By utilizing aluminum coils, buildings contribute to a more sustainable and environmentally-friendly approach, as the material can be recycled repeatedly without compromising its performance. Moreover, the recycling process requires significantly less energy compared to primary aluminum production, resulting in reduced greenhouse gas emissions. In conclusion, aluminum coils play a crucial role in enhancing the energy efficiency of buildings through their high conductivity, lightweight nature, corrosion resistance, and recyclability. By facilitating efficient heat transfer, reducing energy consumption, and promoting sustainability, aluminum coils play a vital role in improving the energy efficiency of HVAC systems and overall building performance.

- Q: What are the common industry standards for aluminum coil specifications?

- Various organizations, such as the Aluminum Association (AA) and the American Society for Testing and Materials (ASTM), establish the common industry standards for aluminum coil specifications. These standards guarantee consistency and uniformity in the manufacturing and utilization of aluminum coils in different industries. The Aluminum Association (AA) is responsible for defining the standards for aluminum alloys and their corresponding temper designations. By classifying aluminum alloys based on their chemical composition and mechanical properties, the AA enables manufacturers to produce coils with specific characteristics suitable for different applications. For instance, AA 3003 is commonly utilized for general-purpose coils, while AA 5052 is preferred in marine applications due to its superior corrosion resistance. Aside from alloy classification, the AA also provides guidelines regarding coil dimensions, tolerances, and surface finishes. These specifications ensure that aluminum coils adhere to the required dimensions and quality standards, facilitating their integration into various manufacturing processes. The American Society for Testing and Materials (ASTM) also holds a significant role in establishing standards for aluminum coil specifications. ASTM offers guidelines for different tests and procedures to assess the quality and performance of aluminum coils. These tests encompass mechanical property evaluations, such as tensile strength and elongation, as well as assessments of surface finish, corrosion resistance, and dimensional stability. Furthermore, specific industries may have their own set of standards for aluminum coils used in their applications. For instance, the automotive industry could have industry-specific standards to ensure compliance with particular performance requirements in vehicle manufacturing. In conclusion, the common industry standards for aluminum coil specifications cover alloy designation, dimensional tolerances, surface finishes, and mechanical properties. Adhering to these standards guarantees consistency, quality, and compatibility across diverse industries and applications.

- Q: Can aluminum coils be used in food storage facilities?

- Yes, aluminum coils can be used in food storage facilities. Aluminum is a widely used material in the food industry due to its excellent properties such as its lightweight, durability, corrosion resistance, and heat conductivity. These qualities make aluminum coils suitable for various applications in food storage facilities. Aluminum coils can be utilized in refrigeration systems, air conditioning units, and food storage cabinets, among others. Additionally, aluminum is non-toxic and does not react with food or alter its taste, making it a safe option for food storage. However, it is important to ensure that the aluminum coils used in food storage facilities are properly cleaned and maintained to prevent any potential contamination.

Send your message to us

S600 Aluminum Coil Price for Wooden Grain Coating Aluminium Coil AA3003 for Roller Shutter Doors

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords