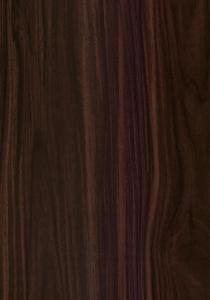

Aluminum Coil 3003 with Wood Grain Coating

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium coated sheetand coil choose aluminium sheet coil as raw material, after de-ester, cleaning,passivation layer processing, and then painting on this basis, the paint areprovided by famous international companies like PPG and Valspar from UnitedStates or Becker from Sweden, represent the most advanced level in the world.After the test of exposure by natural light in Florida, the quality assurance is more than morethan 20 years. As poor performance of color coated steel corrosion, rust,yellow rust after a large amount of the deficiency of serious impact on thebuilding's overall appearance. However, because of the advantages of rawmaterials, Aluminium coated coil have a high strength, corrosion resistance,high weather resistance, can be used recycle, save energy and protect theenvironment and other characteristics. Not only have the same strength with colorcoated steel, but also overcome the shortage of color coated steel. So, the Aluminiumcoated coil has been widely used as roofing and ceiling decorative envelopesystem board in modern constructions like large factories, exhibition halls,stadiums, airports, train station hospital and so on. We can choose Aluminiumcoated coil in different thickness and color, by cutting, pressing, punching,bending and other follow-up molding process for large span, the larger theoverall roofing, wall decorative panels used in construction; or cut them intosmall panels by bending, stamping mold or other processing for indoordecorative roofing plate; we can also composite them with polyurethane foam oraluminium honeycomb for energy-saving decorative wall plates.

Alloy | 1050,1060,1100,3003,3004,3005,3104,3105,5052,5005,8011 |

Temper | O,H42,H44,H46,H48 |

Thickness (mm) | 0.25mm-1.5mm for aluminium coated coil; 1.50mm-4.0mm for aluminium coated sheet. |

Width (mm) | 100mm to 2000mm |

Length (mm) | 800mm to 6000mm for sheet |

- Q: a) Although Aluminium is a reactive metal, it is used to make door frames and window frames.b) Although Aluminium conducts heat, it is used to make blankets, which are good thermal insulators.

- a] AL is used to make frames because it is light, not costly and strong.

- Q: How do aluminum coils perform in saltwater environments?

- Aluminum coils perform exceptionally well in saltwater environments due to their natural resistance to corrosion. Unlike other metals, aluminum forms a protective oxide layer when exposed to saltwater, creating a barrier that prevents further corrosion. This oxide layer acts as a durable and long-lasting shield against the harsh effects of saltwater, ensuring the longevity and performance of aluminum coils in marine applications. Additionally, aluminum coils are lightweight and possess high thermal conductivity, making them popular choices for heat exchangers and condensers in saltwater-based cooling systems. Overall, aluminum coils are highly reliable and efficient in saltwater environments, making them a preferred choice for various marine applications.

- Q: What are the different types of protective coatings for aluminum coils?

- There are several different types of protective coatings that can be used for aluminum coils. These coatings are designed to enhance the durability and lifespan of the coils, as well as protect them from various environmental factors. 1. Polyester Coatings: Polyester coatings are commonly used for aluminum coils due to their excellent resistance to UV rays and weathering. They provide good color retention and are available in a wide range of colors. Polyester coatings are often used in architectural applications where aesthetics are important. 2. Polyvinylidene Fluoride (PVDF) Coatings: PVDF coatings are known for their exceptional resistance to fading, chalking, and chemical exposure. They have high weatherability and can withstand extreme temperatures, making them suitable for harsh environments. PVDF coatings are commonly used in industrial and commercial applications. 3. Epoxy Coatings: Epoxy coatings offer strong adhesion and excellent corrosion resistance. They provide a barrier against moisture and chemicals, making them suitable for applications where the coils may be exposed to harsh conditions. Epoxy coatings are often used in marine and industrial settings. 4. Acrylic Coatings: Acrylic coatings provide good adhesion and flexibility. They offer moderate weather resistance and can be easily applied and repaired. Acrylic coatings are commonly used in various applications, including automotive and general industrial uses. 5. Polyurethane Coatings: Polyurethane coatings provide excellent resistance to abrasion, chemicals, and weathering. They offer superior durability and are often used in demanding applications where the coils may be exposed to harsh conditions or heavy wear. 6. Silicone Coatings: Silicone coatings offer outstanding resistance to extreme temperatures and UV exposure. They have excellent weatherability and can withstand prolonged exposure to sunlight without degradation. Silicone coatings are commonly used in applications such as automotive parts and outdoor equipment. It is important to select the appropriate protective coating based on the specific requirements of the aluminum coils and the intended application. The choice of coating will depend on factors such as the level of protection needed, the desired appearance, and the environmental conditions the coils will be exposed to.

- Q: metals an aluminum can is made of, cast aluminum, 6160 aluminum, sheet aluminum

- the aluminum is alloyed with various metals to change the characteristics of the aluminum the link below shows a table showing the various chemical/metals added to aluminum to make different alloys

- Q: Are there any recycling programs for used aluminum coils?

- Indeed, recycling programs for used aluminum coils are readily accessible. Aluminum, being highly recyclable, can be melted down and repurposed without compromising its quality. Numerous recycling centers and scrap metal yards willingly accept aluminum coils for recycling purposes. Furthermore, certain HVAC companies, which frequently employ aluminum coils in air conditioning systems, have implemented their own recycling initiatives. It is advisable to consult your local recycling center or HVAC companies to obtain information regarding the specific recycling programs available for used aluminum coils in your vicinity.

- Q: What's the difference between an aluminum alloy strip and an aluminum coil?

- The specifications are different. Generally speaking, the aluminum strips are of small size, and the aluminum rolls are of large size

- Q: What specific conditions or precautions are necessary to ensure the proper storage of aluminum coils to maintain their quality and prevent damage?

- <p>Yes, there are special requirements for storing aluminum coils to ensure their quality and prevent damage. Aluminum coils should be stored in a cool, dry place away from direct sunlight and moisture. They should be kept on flat, level surfaces with proper support to prevent warping or denting. It's also important to avoid stacking them too high to prevent crushing. Additionally, coils should be protected from contact with corrosive materials or chemicals that could cause oxidation or staining. Proper labeling and tracking of coils is also essential for inventory management.</p>

- Q: What does it mean to slice aluminum coil by decoiler machine?

- The operating procedures of decoiler machine: 1, Select appropriate aluminum coil according to production work order requirement to be processed, paying attention to the thickness, width and material of aluminum coil. 2, Put the aluminum coil into the coil loading car with traveling crane and inch the car into the uncoiler. The aluminum coil and decoiler machine should be in the same direction. Hold the aluminum coil down with leading head, and open the auxiliary bearing. 3, Turn on the shovel head, and inch the uncoiler to lead the aluminum sheet into the leveler. Adjust the leveler according to the thickness and width of aluminum sheet to ensure the flatness. 4, Turn on the front gap bridge and back gap bridge in control main platform, inch the leveler to lead aluminum sheet into re-leveler. Adjust the re-leveler to ensure the flatness of aluminum sheet. Put it into the shear gauge and plate shearer. 5, Take back the front and back gap bridge. Inch the plate shearer to cut off the sheet head and shear the aluminum sheet according to production work order. Check the first sheet to see whether it meets the quality standard and whether there is defect in flatness, length, diagonal, and surface of aluminum sheet. If it is qualified, turn on the conveyor. Put the aluminum sheet holder on the pallet. Adjust the pallet according to the width and length of aluminum sheet. Input quantity and length on the control main platform. Then turn on the auto control to produce automatically. The production process can be observed at any time. 6, If there is aluminum coil left, unwind, package and put it into storage in reverse steps.

- Q: How do aluminum coils perform in corrosive environments?

- Due to their inherent properties and protective coatings, aluminum coils exhibit exceptional performance in corrosive environments. When exposed to air, aluminum forms a natural oxide layer on its surface, which acts as a protective barrier against corrosion. This oxide layer displays high resistance to various corrosive agents, including saltwater, acids, and atmospheric pollutants. Moreover, aluminum coils can receive additional protection through diverse coatings and treatments, further enhancing their resistance to corrosion. These protective coatings can be organic, such as paint or lacquer, or inorganic, like anodizing or chemical conversion coatings. The combination of aluminum's natural oxide layer and supplementary protective coatings makes aluminum coils highly reliable and durable in corrosive environments. This corrosion resistance is especially advantageous in industries such as marine, chemical processing, and coastal applications, where exposure to saltwater or aggressive chemicals is commonplace. In addition, aluminum coils are lightweight, contributing to their versatility and ease of installation, making them suitable for a wide range of corrosive environments. This lightweight property also aids in reducing transportation costs and energy consumption during the installation process. In conclusion, aluminum coils are well-suited for corrosive environments due to their inherent corrosion resistance and the availability of protective coatings. Their durability, lightweight nature, and resistance to corrosion make them the ideal choice for numerous industries and applications, where longevity and performance are essential considerations.

- Q: How do aluminum coils contribute to the reduction of carbon footprint?

- There are several ways in which aluminum coils can contribute to reducing the carbon footprint. Firstly, due to its lightweight nature, aluminum requires less energy for transportation compared to heavier materials like steel. This leads to lower fuel consumption and emissions during transportation, ultimately reducing the overall carbon footprint. Furthermore, aluminum is highly recyclable and can be recycled indefinitely without any loss in quality. Recycling aluminum requires significantly less energy (up to 95% less) compared to producing new aluminum from raw materials. By utilizing aluminum coils, which can be easily recycled, we can decrease the demand for new aluminum production. Consequently, this reduces the carbon emissions associated with extracting and refining raw materials. In addition, aluminum coils possess excellent thermal conductivity properties. This makes them highly efficient for various heating and cooling systems, including air conditioning units and heat exchangers. By incorporating aluminum coils into these applications, energy consumption is minimized as they facilitate the transfer of heat more efficiently. This results in lower energy consumption and reduced carbon emissions. Lastly, aluminum coils have a longer lifespan compared to materials such as copper or steel. As a result, they require less frequent replacement, leading to reduced waste generation and lower carbon emissions associated with manufacturing and disposing of new coils. Overall, by opting for aluminum coils instead of other materials, we can make significant progress in reducing carbon emissions and promoting a more sustainable future. The utilization of aluminum coils offers benefits through their lightweight nature, recyclability, thermal conductivity properties, and longer lifespan in contributing to the reduction of the carbon footprint.

Send your message to us

Aluminum Coil 3003 with Wood Grain Coating

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords