Q235 Stainless steel equal angle for construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Q235 Stainless steel equal angle for construction at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Q235 Stainless steel equal angle for construction are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Q235 Stainless steel equal angle for construction are durable, strong, and resist corrosion.

Main Product Features:

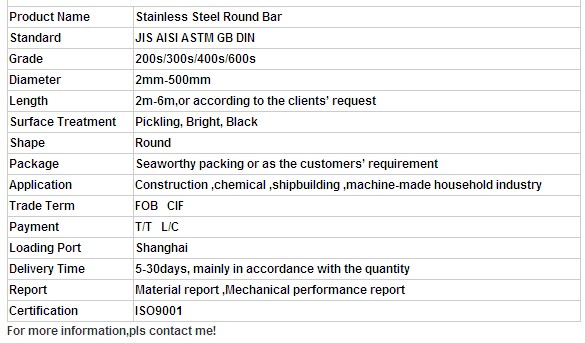

Specifications

stainless steel round bar

1.Specification:12-300mm

2.Material:304 316

3.Length:standard 6m

FAQ:

Q1: What makes stainless steel stainless?

A1: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q2: Can stainless steel rust?

A2: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

- Q: Are steel round bars used in the construction industry?

- Yes, steel round bars are commonly used in the construction industry. They are versatile and can be used in various applications, such as reinforcing concrete structures, providing structural support in buildings, and fabricating components for bridges, highways, and other infrastructure projects. Steel round bars offer high strength and durability, making them suitable for withstanding heavy loads and harsh environmental conditions. Additionally, their uniform shape and smooth surface allow for easy welding, bending, and machining, which makes them an ideal choice for construction projects.

- Q: Are steel round bars suitable for use in the construction industry?

- Yes, steel round bars are commonly used in the construction industry due to their strength, durability, and versatility. They provide structural support in various applications such as reinforcement in concrete, framing, and the creation of beams and columns. Additionally, steel round bars can be easily fabricated, welded, and formed into different shapes, making them a suitable choice for a wide range of construction projects.

- Q: What are the advantages of using nickel-aluminum alloy steel round bars?

- There are several advantages to using nickel-aluminum alloy steel round bars. Firstly, these bars have excellent corrosion resistance, making them suitable for use in harsh environments or applications where they may come into contact with corrosive substances. Secondly, the alloy steel composition provides high strength and durability, making these bars capable of withstanding heavy loads or extreme temperatures. Additionally, nickel-aluminum alloy steel round bars offer good thermal conductivity, allowing for efficient heat transfer in various applications. Lastly, these bars are easily machinable, enabling precise shaping and customization to meet specific project requirements.

- Q: How are steel round bars heat treated?

- Steel round bars are heat treated to increase their strength and hardness while also improving their mechanical properties. The heat treatment process typically involves three main steps: heating, soaking, and cooling. Firstly, the steel round bars are heated to a specific temperature, known as the austenitizing temperature. This temperature is usually above the critical temperature of the steel, which allows the material to transform into its austenite phase. The austenitizing temperature varies depending on the type of steel and the desired properties. Once the steel round bars reach the austenitizing temperature, they are soaked at this temperature for a specific duration. The soaking time allows for the complete transformation of the microstructure, ensuring uniformity and avoiding any thermal gradients within the material. The soaking time is crucial in determining the final properties of the steel. After the soaking period, the steel round bars are rapidly cooled in a process called quenching. Quenching is typically done by immersing the bars in a quenching medium, such as oil, water, or air, depending on the desired hardness and properties. The quenching process rapidly cools the bars, causing a martensitic transformation in the steel's microstructure. This transformation results in increased hardness and strength. Following quenching, the steel round bars may undergo an additional step called tempering. Tempering involves reheating the bars to a lower temperature, typically below the austenitizing temperature. This step aims to reduce the brittleness caused by the quenching process while further improving the material's toughness and ductility. Overall, the heat treatment process for steel round bars involves heating to the austenitizing temperature, soaking for a specific duration, quenching to rapidly cool and harden the material, and potentially tempering to achieve the desired properties. This process allows for the customization and enhancement of the steel's mechanical properties, making it suitable for various applications.

- Q: What are the typical hardness values for different grades of steel round bars?

- The hardness values for different grades of steel round bars can vary depending on the specific grade and the manufacturing process used. However, there are some typical hardness values that can be used as a general guideline. For low carbon or mild steel round bars, the typical hardness values range from about 120 to 250 Brinell Hardness (HB). These grades of steel are known for their relatively low strength and hardness but can be easily machined and welded. Medium carbon steel round bars, commonly used in applications that require higher strength and hardness, typically have hardness values ranging from about 200 to 400 HB. These grades of steel are often used in construction, automotive, and machinery industries. High carbon or alloy steel round bars, which offer even greater strength and hardness, can have hardness values ranging from 400 to 700 HB or even higher. These grades of steel are commonly used in applications that require high wear resistance, such as cutting tools, gears, and bearings. It is important to note that these hardness values are approximate and can vary depending on factors such as heat treatment, alloy composition, and the specific manufacturing process employed. Therefore, it is always recommended to consult the manufacturer's specifications or conduct hardness testing to determine the exact hardness values for a specific grade of steel round bar.

- Q: How are steel round bars priced?

- Several factors typically determine the price of steel round bars. The cost of raw materials, specifically steel billets or ingots used in production, is a key consideration. The price of these materials can fluctuate based on market conditions, including supply and demand dynamics and changes in input costs. The manufacturing process also plays a role in pricing. Transforming raw materials into finished round bars incurs expenses such as energy consumption, labor costs, and equipment maintenance. The complexity of the manufacturing process and the efficiency of production facilities can affect these costs. Market conditions significantly influence steel round bar pricing. Global economic trends, industry demand, and competition among suppliers all impact the market price. Manufacturers may charge a premium when there is high demand, while prices may be lower during periods of oversupply as suppliers compete for customers. The size, grade, and quality of the steel round bars can also affect pricing. Larger diameter bars or specialty grades that require additional processing steps or high-quality raw materials may be priced higher than standard sizes or lower-grade bars. Transportation costs and logistics are additional factors that influence pricing. Shipping distances, freight rates, and any handling fees can increase the overall cost of the product. In conclusion, the pricing of steel round bars is influenced by raw material costs, the manufacturing process, market conditions, the size and grade of the bars, and transportation costs. Understanding these factors helps buyers and sellers negotiate fair prices for steel round bars.

- Q: What are the advantages of using nitriding steel round bars?

- There are several advantages of using nitriding steel round bars. Firstly, nitriding steel round bars have a high surface hardness, which makes them resistant to wear, abrasion, and scratching. This makes them ideal for applications where the material needs to withstand harsh conditions and maintain its integrity over time. Additionally, nitriding steel round bars have improved fatigue and impact strength, making them suitable for heavy-duty applications. They also exhibit good heat resistance and can withstand high temperatures without losing their mechanical properties. Moreover, nitriding steel round bars have excellent corrosion resistance, reducing the need for frequent maintenance and replacement. Overall, the use of nitriding steel round bars offers enhanced durability, strength, and reliability, making them a preferred choice in various industries.

- Q: Can steel round bars be used in the manufacturing of pumps?

- Yes, steel round bars can be used in the manufacturing of pumps. Steel round bars are often used as the primary material for making pump shafts, impellers, and other critical components due to their high strength, durability, and resistance to corrosion. Their uniform shape and consistent mechanical properties make them suitable for creating precise and reliable pump parts.

- Q: How can steel round bars be protected against rust?

- Steel round bars can be protected against rust by applying a protective coating such as paint, galvanizing, or epoxy. Regular maintenance, including cleaning and applying rust inhibitors, is also crucial to prevent rust formation. Additionally, storing the bars in a dry environment and avoiding exposure to moisture can help minimize the risk of rusting.

- Q: What are the advantages of using low-alloy steel round bars?

- Low-alloy steel round bars have become popular in various industries due to several advantages they offer. Firstly, they provide greater strength and durability compared to regular carbon steel, making them suitable for applications requiring high strength and resistance to wear and tear. The addition of alloying elements like manganese, chromium, and nickel enhances the hardness and toughness of the steel, ensuring its reliability and long-lasting nature. Secondly, low-alloy steel round bars exhibit excellent weldability and machinability. The presence of alloying elements allows for better control over the grain structure, resulting in improved weldability. This means that these bars can be easily welded and fabricated into complex shapes without compromising their structural integrity. Additionally, their machinability enables efficient processing and customization according to specific requirements. Furthermore, low-alloy steel round bars offer enhanced resistance to corrosion and atmospheric conditions. The alloying elements create a protective oxide layer on the surface, preventing rusting and deterioration over time. This makes them ideal for outdoor applications in harsh environments, such as construction, marine, and oil and gas industries. Moreover, low-alloy steel round bars are a cost-effective alternative to higher-alloy or stainless steel options. While providing similar strength and performance, low-alloy steel is generally more affordable, making it a viable option for projects with budget constraints. This cost-effectiveness, combined with their durability and versatility, makes low-alloy steel round bars a preferred choice for a wide range of applications. In conclusion, the advantages of low-alloy steel round bars include increased strength and durability, excellent weldability and machinability, resistance to corrosion, and cost-effectiveness. These properties make them a reliable and versatile material for various industries, contributing to their widespread use in numerous applications.

Send your message to us

Q235 Stainless steel equal angle for construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords