Rustic Red Aluminum Coil - 0.19mm x 94mm Lacquered Aluminium Strip for Vial Seals

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

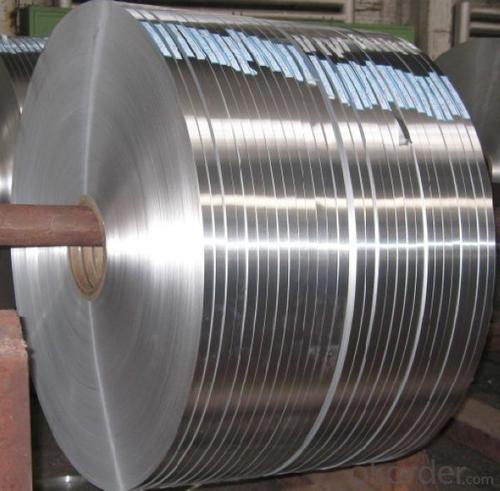

Aluminium Strip 0.19mm X 94mm Lacquered for Vial Seals

l Product Specification

1.Alloy 8011 temper h14 thickness 0.17-0.24mm

2.Width 60-800mm id 76mm 152mm

3.Coating type :

a. One side golden n other side protective lacquered

b. both sides clear lacquered

4.test item: autoclave test . Hgcl2 test

5.Tensile strength : 125-155mpa , elongation 2.5-3.5% , earring 2%

6.Packing: wooden boxes . 50kg or 100kg

7.Application : vial seals, pharmaceutical caps

8. we can gurantee quality and very good service

l Packaging & Delivery

Packaging detail: Seaworthy Export Standard Wooden Pallet and with damp proof film as first layer, Kraft paper as second layer, Cardboard card as third layer Criss-cross steel strip to fix outside

Delivery detail: About 15 days

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323. |

l CNBM World Wide

l Products Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T

- Q: Can aluminum coils be used for architectural applications?

- Aluminum coils are indeed applicable for architectural purposes. With its versatility and lightweight nature, aluminum is an ideal material that boasts exceptional resistance against corrosion, making it suitable for numerous architectural applications. Exterior cladding, roofing, facades, and even interior uses like ceilings and wall panels can all benefit from the utilization of aluminum coils. These coils are easily malleable, cuttable, and moldable, allowing for flexibility in design and innovative architectural solutions. Moreover, aluminum coils can be coated with diverse finishes, such as paint or anodized coatings, to enhance both aesthetics and durability. All in all, due to their adaptability, durability, and aesthetic charm, aluminum coils are highly favored within the architectural industry.

- Q: Are aluminum coils suitable for corrosion-resistant applications?

- Yes, aluminum coils are suitable for corrosion-resistant applications. Aluminum has natural corrosion-resistant properties as it forms a protective oxide layer when exposed to air, which prevents further corrosion. Additionally, aluminum can be further enhanced with various coatings or treatments to increase its resistance to corrosion, making it a suitable choice for applications where corrosion resistance is required.

- Q: Is it possible to determine the spring constant of an aluminum coil using a spring compressor?

- <p>Yes, you can use a spring compressor to measure the spring constant of an aluminum coil. The spring constant (k) can be calculated using Hooke's Law, which states that the force exerted by a spring is proportional to its displacement (F = kx). By applying a known force to the spring and measuring the resulting displacement, you can calculate the spring constant. A spring compressor can apply a controlled force, and a displacement gauge can measure the compression, allowing you to determine the spring constant accurately.</p>

- Q: Can aluminum coils be used in the production of electronic components?

- Yes, aluminum coils can be used in the production of electronic components. Aluminum is a commonly used material due to its lightweight, conductivity, and corrosion resistance properties. It is often used in electronic devices such as capacitors, inductors, and transformers.

- Q: where is aluminum found in the world or in the universe?do u think aluminum is more valuable to people than gold?why or why not?im just lazy to look up the answers and person 4 best answer 10points

- where is aluminum found in the world aluminum is in fact the third most common element in the Earth's crust, and it is the most common metallic element on Earth. In a pure form, aluminum is silvery white and extremely lightweight. aluminum is more valuable to people than gold? aluminum continues to remake the modern world. We can see it everywhere; in architecture, transportation, electrical cables, communications and consumer products. Because it’s light-weight, strong, versatile and easy to recycle, aluminum is becoming more and more valuable in our daily lives melting point and boiling point Melting Point: 933.437 K (660.323°C or 1220.581°F) Boiling Point: 2792 K (2519°C or 4566°F)

- Q: Are aluminum coils suitable for interior decorative applications?

- Yes, aluminum coils are suitable for interior decorative applications. They are lightweight, durable, and can be easily shaped and colored to match various design requirements. Additionally, aluminum coils offer resistance to corrosion, making them suitable for long-term use in interior spaces.

- Q: This question asks about the current market demand for aluminum coil, which is a versatile material used in various industries.

- <p>The market demand for aluminum coil is significant and growing due to its wide range of applications across industries such as construction, automotive, aerospace, packaging, and electronics. Its lightweight, corrosion resistance, and recyclability make it a preferred material for many applications. The demand is influenced by economic growth, technological advancements, and sustainability initiatives. As countries focus on greener construction and manufacturing processes, the demand for aluminum coil is expected to increase further.</p>

- Q: How are aluminum coils cut to length?

- The process of cutting aluminum coils to length is typically done using two methods: shearing and slitting. Shearing involves the use of sharp blades to cut the coil into shorter lengths, which is commonly used for thicker coils. On the other hand, slitting is a process where the coil is passed through rotating circular knives to cut it into narrower strips of the desired width, often used for thinner coils. Both shearing and slitting can be done manually or automatically, depending on the scale of production and project requirements. Large-scale production usually utilizes automated cutting machines for their higher precision and faster cutting speeds. It is important to note that during the cutting process, the coil is usually uncoiled and guided through the cutting machine. Once the desired length or width is achieved, the cut aluminum pieces are collected, bundled, and prepared for further processing or distribution.

- Q: Can aluminum coils be used in food storage facilities?

- Yes, aluminum coils can be used in food storage facilities. Aluminum is a safe and commonly used material for food storage due to its non-reactive properties and resistance to corrosion, making it suitable for maintaining food quality and preventing contamination.

- Q: How are aluminum coils used in the production of battery enclosures?

- Due to their exceptional properties, aluminum coils find wide application in the manufacturing of battery enclosures. Firstly, aluminum, being a lightweight material, is perfect for creating battery enclosures that are lightweight themselves, a crucial feature for portable devices and electric vehicles where weight reduction is of utmost importance. Moreover, aluminum coils can be easily shaped and sized to accommodate specific battery designs, giving manufacturers the ability to customize the enclosures. This flexibility in shaping also aids in optimizing space utilization and enhancing the overall efficiency of the battery system. Furthermore, aluminum exhibits high resistance to corrosion, a vital characteristic for battery enclosures that are frequently exposed to harsh chemicals and environments. This corrosion resistance ensures the longevity and dependability of the enclosure, safeguarding the battery cells from harm and guaranteeing safe operation. Additionally, aluminum possesses excellent thermal conductivity, enabling efficient dissipation of heat generated during battery charging and discharging. This is crucial in preventing overheating and maintaining the optimal temperature range for optimal battery performance. In conclusion, aluminum coils play a pivotal role in the production of battery enclosures by providing lightweight, customizable, corrosion-resistant, and thermally conductive properties. These properties contribute to the overall efficiency, safety, and durability of battery systems employed in a wide range of applications, including consumer electronics, electric vehicles, and renewable energy storage.

Send your message to us

Rustic Red Aluminum Coil - 0.19mm x 94mm Lacquered Aluminium Strip for Vial Seals

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords