Aluminum Coated Aluminium Coils for Lids and Tabs

- Loading Port:

- Yantai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

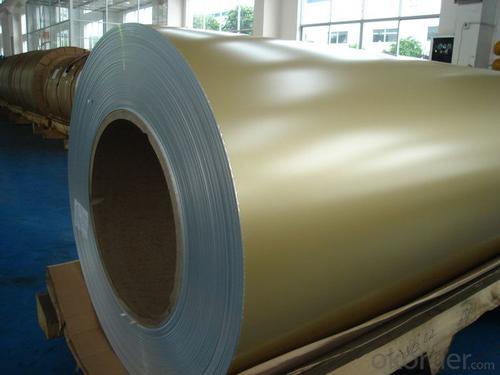

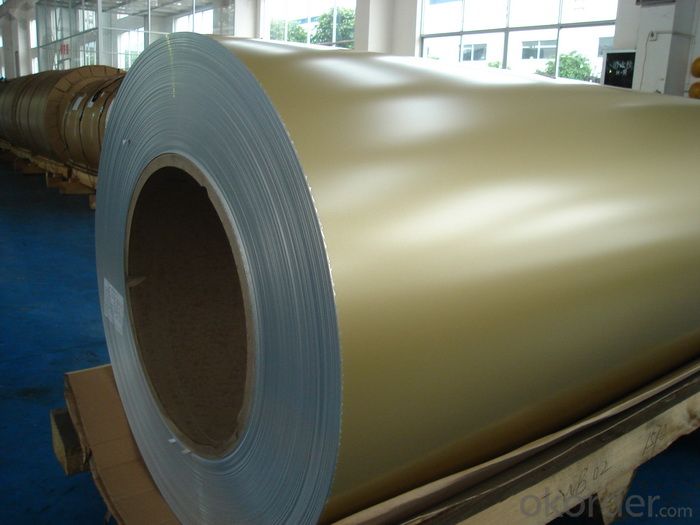

1.Structure of Coated Aluminium Coils for Lids and Tabs

We professionally produce coated aluminium coils, which are widely used in beverage can lids and tabs (aluminium easy-can-cover and ring-pull).

We normally use 5052 H19; 5052, H36; 5182 H19; 5182 H48, 5182 H49. Based on ordinary aluminum, we add Mn and Mg, so as to increase tensile strength and elongation.

We use large wave shear, transverse shear and longitudinal cut system so as to meet different specifications of customers.

As for coating, we normal coat gold color for lids, red, blue, etc for tabs. We also can adjust coating according to color of customers and offer personalized services.

2. Main Features of Coated Aluminium Coils for Lids and Tabs

• Light Weight

• High Flatness

• Good Weathering

• Colorful

• Recycling

• Saving Energy

• Rustproof

3. Coated Aluminium Coils for Lids and Tabs Images

4. Specification of Coated Aluminium Coils for Lids and Tabs

ALLOY | TEMPER | THICKNESS | WIDTH | COIL OR LENGTH |

5052 5182 | H19 H36 H48 H49 | 0.22-0.5mm | 500-1600mm | AS PER YOUR REQUIREMENTS |

A.What about inspections to guarantee quality?

For each order, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported?

We have exported to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: Is it possible to use aluminum as a substance that accelerates chemical reactions?

- <p>Aluminum is not typically used as a catalyst in chemical reactions. Catalysts are substances that increase the rate of a chemical reaction without being consumed in the process. Aluminum, being a metal with a +3 oxidation state, does not readily participate in reactions where it could act as a catalyst. Instead, it is more commonly used in its elemental form for structural purposes or as a reducing agent in certain chemical processes. However, aluminum compounds, such as alumina (Al2O3), can be used as catalysts or catalyst supports in specific industrial applications.</p>

- Q: Explain the connection between aluminum and its interaction with electromagnetic radiation.

- <p>Aluminum has a unique relationship with electromagnetic radiation due to its reflective and conductive properties. It is a good reflector of visible light and infrared radiation, which is why it is used in applications such as mirrors and reflective coatings on windows to reduce heat transfer. Additionally, aluminum's high electrical conductivity makes it an excellent shield against electromagnetic radiation, as it can absorb and reflect a significant amount of electromagnetic waves. This property is utilized in various industries, including electronics and aerospace, to protect sensitive equipment from electromagnetic interference.</p>

- Q: Is it safe or permissible to use aluminum in food packaging materials?

- <p>Yes, aluminum is commonly used in food packaging due to its lightweight, durability, and excellent barrier properties against air, moisture, and light. It is used in various forms such as aluminum foil, cans, and flexible packaging materials. However, it's important to ensure that the aluminum packaging is food-grade and complies with safety regulations to prevent any potential health risks associated with aluminum exposure.</p>

- Q: Is it possible to join aluminum pieces together using welding techniques?

- <p>Yes, aluminum can be welded. Welding aluminum is a common practice in various industries due to its lightweight and corrosion-resistant properties. Techniques such as Gas Metal Arc Welding (GMAW), Gas Tungsten Arc Welding (GTAW), and Shielded Metal Arc Welding (SMAW) are used. However, aluminum welding requires specific precautions, such as using a clean, dry surface and a proper shielding gas to prevent oxidation, as aluminum readily reacts with oxygen.</p>

- Q: This question asks for a list of negative aspects or drawbacks associated with the use of aluminum.

- <p>Aluminum, while widely used, has several disadvantages. It is non-magnetic and non-conductive, which limits its use in certain applications requiring these properties. Aluminum is also relatively soft and can dent or scratch easily, affecting its durability in some contexts. Additionally, its production process is energy-intensive and contributes to environmental pollution. Furthermore, aluminum can have negative health impacts if ingested in large quantities, potentially leading to neurological disorders. Lastly, aluminum's light weight can be a disadvantage in applications where greater strength or weight is required.</p>

- Q: Is it possible to utilize aluminum in the construction or components of electronic devices?

- <p>Yes, aluminum is commonly used in electronic devices. It is valued for its lightweight, high thermal conductivity, and corrosion resistance. Aluminum is often used in heat sinks to dissipate heat from electronic components, as well as in the casings of devices for structural support and durability. Additionally, aluminum is used in the manufacturing of electrolytic capacitors and serves as a conductive material in various electronic components due to its good electrical conductivity.</p>

- Q: Is it safe to use aluminum cookware for cooking food?

- <p>Yes, aluminum can be used to make cookware that is safe for cooking food. Aluminum cookware is widely used due to its lightweight, durability, and good heat conductivity. While there were concerns about aluminum's potential health effects, current research indicates that the amount of aluminum leached into food during normal cooking is minimal and not harmful to health. However, it's important to avoid using abrasive cleaners or utensils on aluminum cookware to prevent scratching, as this could increase the amount of aluminum that might be released into food.</p>

- Q: Explain the process by which aluminum forms alloys.

- <p>Aluminum forms alloys by combining with other elements, such as copper, magnesium, silicon, manganese, and zinc, among others. This process involves melting aluminum and the alloying elements together in a furnace. The molten mixture is then cooled and solidified to form an alloy. The resulting alloy has properties that are different from pure aluminum, such as increased strength, corrosion resistance, and improved machinability. The specific properties of the alloy depend on the elements added and their proportions. Alloying allows for the customization of aluminum's characteristics to suit various applications in industries like aerospace, automotive, and construction.</p>

- Q: What are the various applications of aluminum in the construction industry?

- <p>Aluminum is widely used in construction due to its lightweight, durability, and resistance to corrosion. It is utilized in the manufacturing of window frames, doors, roofing, and facades for its strength and low maintenance requirements. Aluminum is also used in structural components such as beams and columns, and in the construction of bridges and high-rise buildings. Its malleability allows for easy shaping and forming, making it ideal for intricate designs. Additionally, aluminum's thermal conductivity and reflectivity make it suitable for energy-efficient construction.</p>

- Q: What are the various electronic components that utilize aluminum as a primary material?

- <p>Aluminum is used in several types of electronic components due to its good thermal conductivity, lightweight, and corrosion resistance. Some of the common components include: 1. Capacitors: Aluminum electrolytic capacitors are widely used for their high capacitance and low cost. 2. Heat sinks: Aluminum is a popular choice for heat sinks due to its ability to dissipate heat efficiently. 3. Semiconductors: Aluminum is used in semiconductor manufacturing, particularly for interconnects and as a barrier layer. 4. Conductive adhesives: Aluminum-filled adhesives are used for bonding components in electronics. 5. Wires and cables: Aluminum wire is used in some applications due to its lower weight compared to copper. 6. Reflectors: Aluminum is used in light reflectors for its reflective properties. 7. Housings and enclosures: Aluminum is used in the construction of electronic device casings for its strength and lightweight properties.</p>

Send your message to us

Aluminum Coated Aluminium Coils for Lids and Tabs

- Loading Port:

- Yantai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords