Fiberglass Mat Tissue Spray Up Roving, Fiber Glass Gun Roving

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Roving Fiberglass Fiberglass Sprary Up Roving, Fiber Glass Gun Roving,

Introduction:

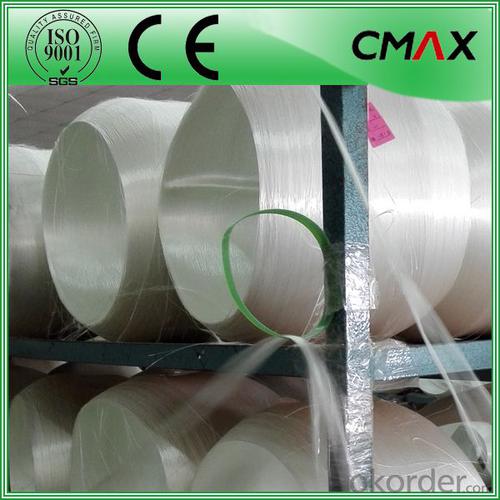

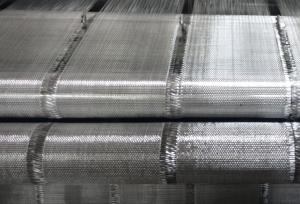

Direct Roving is coated with a silane-based sizing and compatible with unsaturated resin, vinyl resin, and epoxy resin. It is designed for filament winding, pultrusion, and weaving applications.

Direct Roving is suitable for use in pipes, pressure vessels, gratings, and profiles, and the woven roving converted from it is used in boats and chemical storage tanks.

Product Features:

1.Resistant to ozone, oxygen, light and climate change.

2.High strength, high modulus, low shrink, no deformation.

3.Incombustible. heat insulation, heat preservation.

4.Hgher than working temperature, still keep residual strength.

5.Corrosion resistance.

6.Electrical insulation.

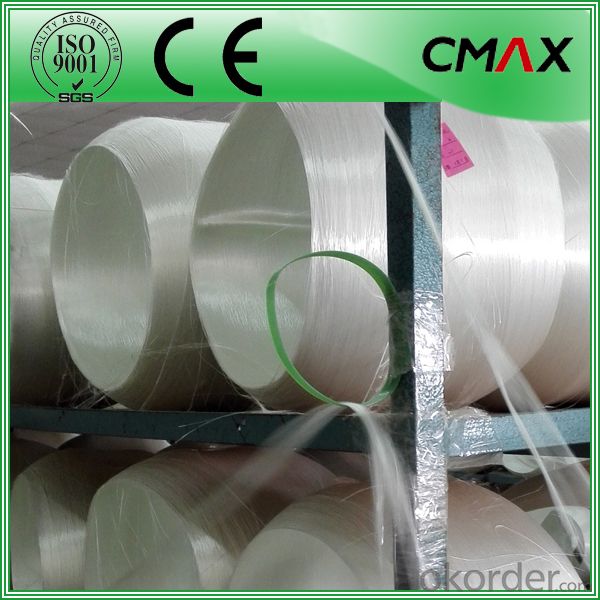

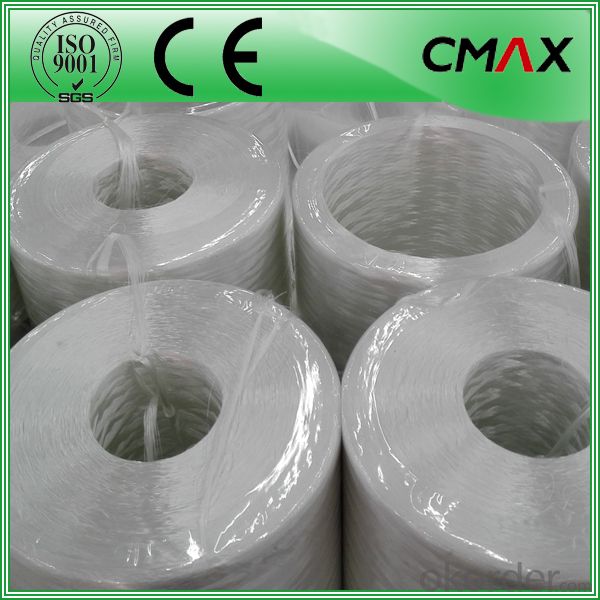

Packaging:

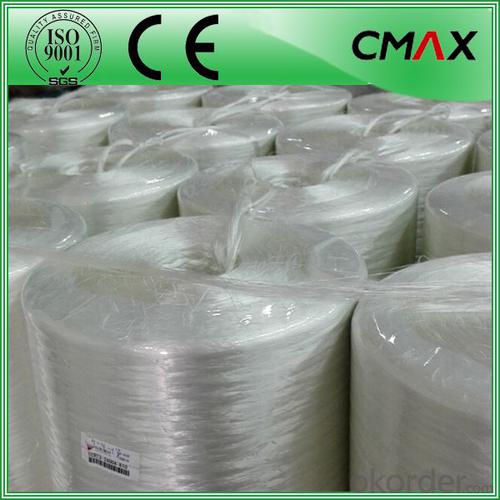

Product is manufactured in form of a roll wrap on a paper tube then after packed in a plastic bag and placed in a cardboard carton. Rolls can be loaded in a container directly or on pallets.

Deposited:

Chopped Strand Mat should be stored in dry, cool, clean and rainproof area. Recommended temperature range of storage is between 15-30 and relative humidity between 40%-70%.

FAQ:

Is sample available ?

Yes, we provide the free samples, but customers themselves need pay the shipping fee

What's your MOQ?

Our MOQ is one 1*20' full container loading

How do you pack the fiberglass

(1) First, the mat is in roll packed in White PE fIlm.

(2) Then the rolls packed in the carton

4.Which knid of payment terms can you accept?

We can accept 30% prepayment, 70% payment before shippment. LC is also accepted

- Q: Can fiberglass mat tissue be used for corrosion-resistant coatings?

- Corrosion-resistant coatings can utilize fiberglass mat tissue, a non-woven fabric composed of fine fiberglass strands bonded together using a binder. Due to its exceptional strength and corrosion resistance qualities, fiberglass mat tissue is commonly employed as a reinforcement material in composite applications. When integrated into corrosion-resistant coatings, fiberglass mat tissue acts as a protective barrier against the corrosive surroundings, safeguarding the underlying surface from deterioration caused by chemicals, moisture, and other corrosive substances. Moreover, fiberglass mat tissue can be impregnated with diverse resin systems that enhance its capacity to resist corrosion. These resin systems offer supplementary safeguard against specific corrosive agents or environments, consequently heightening the effectiveness of the coating. Furthermore, the flexibility and moldability of fiberglass mat tissue enable it to conform effortlessly to intricate shapes and surfaces, guaranteeing comprehensive coverage and protection against corrosion. In conclusion, fiberglass mat tissue is a dependable and efficient material for corrosion-resistant coatings. Its impressive strength, corrosion resistance, and compatibility with various resin systems make it a suitable choice for shielding surfaces in corrosive environments.

- Q: Can fiberglass mat tissue be used for insulation purposes?

- Yes, fiberglass mat tissue can be used for insulation purposes. It is commonly used as a layer in insulation systems to provide thermal resistance and enhance the overall insulation performance.

- Q: Is fiberglass mat tissue resistant to compression?

- Yes, fiberglass mat tissue is resistant to compression.

- Q: What is the flexibility of fiberglass mat tissue?

- Fiberglass mat tissue possesses a remarkable quality known as flexibility, which grants it the capability to bend, conform, or shape itself to various forms or surfaces without succumbing to breakage or compromising its structural integrity. The distinct characteristics of fiberglass, such as its exceptional strength-to-weight ratio and dimensional stability, allow the mat tissue to retain its flexibility while upholding its robustness and longevity. This adaptability endows fiberglass mat tissue with versatility, rendering it suitable for an extensive array of applications spanning from automotive components and construction materials to boat manufacturing. Furthermore, the flexibility of fiberglass mat tissue facilitates effortless cutting, shaping, or layering to meet specific design specifications or seamlessly integrate into intricate or curved surfaces.

- Q: How does the strength of fiberglass mat tissue compare to other reinforcement materials?

- The strength of fiberglass mat tissue is considered to be quite high when compared to other reinforcement materials. Fiberglass mat tissue is made up of numerous glass fibers that are tightly intertwined, resulting in a strong and durable material. This type of reinforcement material is commonly used in applications that require high strength, such as in the construction industry for reinforcing concrete structures, in the automotive sector for manufacturing lightweight yet strong components, and in the aerospace industry for building aircraft parts. Compared to other reinforcement materials like steel or carbon fiber, fiberglass mat tissue offers several advantages. Firstly, it is relatively lightweight, which makes it easier to handle and transport. Additionally, fiberglass mat tissue has a high tensile strength, meaning it can withstand stretching or pulling forces without breaking. It also has good impact resistance and is capable of absorbing energy, which makes it suitable for applications where impact resistance is important. Moreover, fiberglass mat tissue is highly corrosion resistant, making it suitable for use in harsh environments or in contact with chemicals. Unlike steel, it does not rust or deteriorate over time. Furthermore, fiberglass mat tissue is non-conductive, which is beneficial in applications where electrical conductivity can be a safety hazard or interfere with electronic equipment. Overall, the strength of fiberglass mat tissue is considered to be excellent when compared to other reinforcement materials. Its high tensile strength, lightweight nature, corrosion resistance, and impact resistance make it a versatile and widely used material in various industries.

- Q: What is the tensile strength of fiberglass mat tissue?

- The tensile strength of fiberglass mat tissue varies depending on its specific composition and thickness, but it is generally known to have high tensile strength ranging from 200 to 600 MPa (megapascals).

- Q: Can fiberglass mat tissue be used for making electrical enclosures?

- No, fiberglass mat tissue cannot be used for making electrical enclosures. Electrical enclosures require materials that have high electrical insulation properties, such as non-conductive plastics or metals, to ensure safety and prevent electrical hazards.

- Q: Can fiberglass mat tissue be used for insulation in hot climates?

- Yes, fiberglass mat tissue can be used for insulation in hot climates. It has excellent thermal insulation properties and can effectively block heat transfer, making it suitable for use in hot climates to maintain cooler indoor temperatures.

- Q: Can fiberglass mat tissue be used for insulation in cleanrooms?

- Yes, fiberglass mat tissue can be used for insulation in cleanrooms. It is a commonly used material due to its excellent thermal insulation properties, low cost, and high resistance to chemicals and moisture. Additionally, fiberglass mat tissue has low particulate emission, making it suitable for cleanroom environments where maintaining a controlled and sterile atmosphere is crucial.

- Q: Can fiberglass mat tissue be used in corrosive environments?

- Fiberglass mat tissue can be used in corrosive environments to some extent, but its resistance to corrosion depends on the specific composition and quality of the material. Fiberglass mat tissue is typically manufactured using a combination of fiberglass strands and a binder material. While fiberglass itself is generally resistant to corrosion, the binder material used in the mat tissue can vary and affect its resistance to corrosive environments. Some binders may provide better protection against corrosion, while others may be more susceptible to degradation. To enhance the corrosion resistance of fiberglass mat tissue in corrosive environments, additional protective coatings or treatments can be applied. These coatings can provide a barrier against the corrosive elements and extend the lifespan of the material. It is important to consider the specific corrosive environment and consult with experts or manufacturers to determine the suitability of fiberglass mat tissue for a particular application. They can provide guidance on the ideal composition, treatment, and any necessary precautions to ensure optimal performance and durability in corrosive environments.

Send your message to us

Fiberglass Mat Tissue Spray Up Roving, Fiber Glass Gun Roving

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords