Fiberglass Mat Tissue Spray Up Roving with Fiberglass Gun Roving

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Roving Fiberglass Sprary Up Roving, Fiber Glass Gun Roving

Introduction:

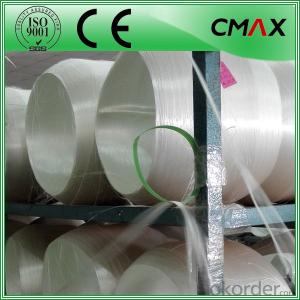

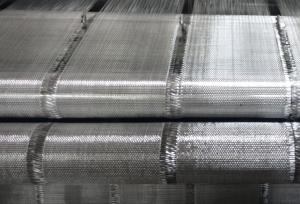

E-glass sprary-up roving, fiberglass gun roving, fiberglass roving is coated with a silance-based sizing, compatible with unsaturated polyester, vinyl ester and polyurethane resins.

It is a versatile general purpose spray-up roving used to manufacture boats, bathroom sinks ,yacht, sanitary ware, swimming pool and automotive parts and also pipe by centrifugal casting process.

Product Features:

1)Silane based coupling agent which delivers most balanced sizing properties.

2)Special sizing formulation which delivers good compatibility with martix resin.

3)Consistent fiber linear density,good mold ability and dispersion

4)Excellent mechanical properties of composite products

Packaging:

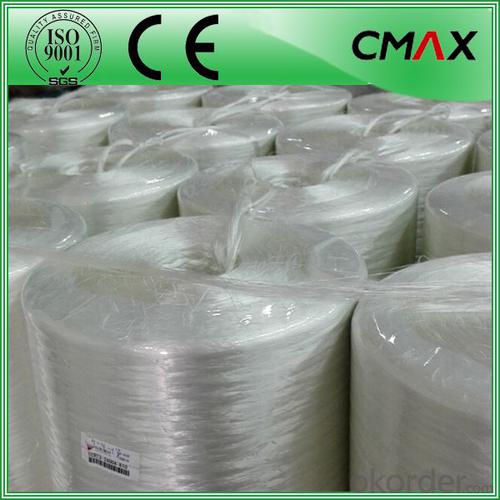

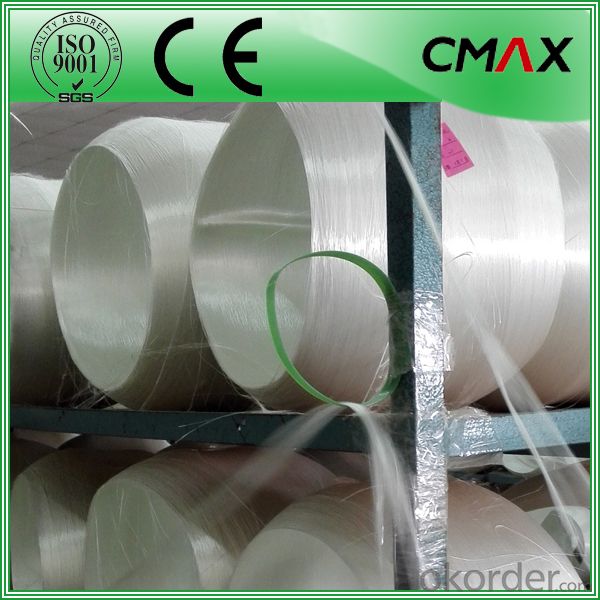

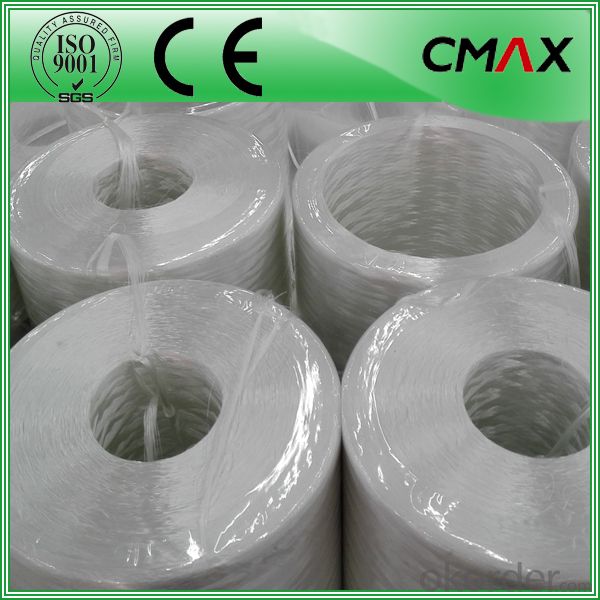

Product is manufactured in form of a roll wrap on a paper tube then after packed in a plastic bag and placed in a cardboard carton. Rolls can be loaded in a container directly or on pallets.

Deposited:

Chopped Strand Mat should be stored in dry, cool, clean and rainproof area. Recommended temperature range of storage is between 15-30 and relative humidity between 40%-70%.

FAQ:

Is sample available ?

Yes, we provide the free samples, but customers themselves need pay the shipping fee

What's your MOQ?

Our MOQ is one 1*20' full container loading

How do you pack the fiberglass

(1) First, the mat is in roll packed in White PE fIlm.

(2) Then the rolls packed in the carton

4.Which knid of payment terms can you accept?

We can accept 30% prepayment, 70% payment before shippment. LC is also accepted

- Q: How does fiberglass mat tissue perform in terms of air permeability?

- Fiberglass mat tissue has low air permeability, meaning it restricts the flow of air.

- Q: How does fiberglass mat tissue perform in terms of UV resistance?

- Fiberglass mat tissue generally performs well in terms of UV resistance. It is designed to withstand prolonged exposure to sunlight without significant degradation or discoloration. However, the specific UV resistance of fiberglass mat tissue can vary depending on the quality and manufacturing process of the material.

- Q: What is the moisture resistance of fiberglass mat tissue?

- The moisture resistance of fiberglass mat tissue is high.

- Q: Can fiberglass mat tissue be used for insulation purposes?

- Indeed, insulation purposes can be achieved using fiberglass mat tissue. This lightweight material is crafted from delicate glass fibers that are skillfully bonded together with a binder. Although it is commonly utilized as a reinforcement material within the construction industry, it also serves as a valuable source of insulation. The thermal insulation properties of fiberglass mat tissue are truly outstanding, rendering it a highly effective option for insulating various structures, including buildings. By impeding heat transfer, it ensures that the interior of a building remains warm during chilly weather and cool during hot spells. Furthermore, its non-combustible nature guarantees a secure choice for insulation purposes. The popularity of fiberglass mat tissue as an insulation material stems from its flexibility and effortless installation. It can be easily cut and molded to fit diverse spaces, making it an adaptable choice for a multitude of construction projects. Additionally, its resistance to moisture, mold, and mildew ensures that its insulation performance remains durable and long-lasting. To summarize, fiberglass mat tissue is indeed a viable option for insulation purposes. Its remarkable thermal insulation properties, non-combustible characteristics, and ease of installation make it an ideal choice for enhancing energy efficiency and insulating buildings.

- Q: Can fiberglass mat tissue be used for making furniture?

- No, fiberglass mat tissue is not suitable for making furniture. It is primarily used in composite materials and construction applications, not for furniture manufacturing.

- Q: Is fiberglass mat tissue suitable for insulation in data centers?

- Yes, fiberglass mat tissue is a suitable material for insulation in data centers. It provides excellent thermal insulation properties, helping to maintain the desired temperature and prevent heat loss. Additionally, fiberglass is fire-resistant and can offer acoustic insulation, reducing noise levels in the data center. Overall, fiberglass mat tissue is a reliable and effective choice for insulation in data centers.

- Q: Can fiberglass mat tissue be used for making swimming pool shells?

- Swimming pool shells can indeed be constructed using fiberglass mat tissue. This material, widely used in the construction and manufacturing industries, possesses remarkable qualities. By combining fine glass fibers with a resin binder, it becomes a lightweight and pliable substance. The utilization of fiberglass mat tissue in swimming pool shell fabrication yields numerous advantages. Primarily, its exceptional resistance to water enables it to excel in pool applications. It also withstands the effects of common pool chemicals like chlorine, ensuring the longevity of the shell. In addition, fiberglass mat tissue is highly adaptable and can be molded into various shapes and sizes. This permits the creation of bespoke swimming pool shells that cater to specific requirements and preferences. Its flexibility also enables it to endure ground movement and temperature changes, thereby guaranteeing the pool shell's structural integrity. Moreover, fiberglass mat tissue boasts a smooth surface finish, providing both visual and tactile appeal. It can be easily painted or coated with gel coats to enhance its appearance and safeguard it from harmful UV rays, preventing discoloration and deterioration over time. In conclusion, fiberglass mat tissue emerges as an exceptional option for constructing swimming pool shells due to its water and chemical resistance, flexibility, durability, and aesthetic appeal.

- Q: How does fiberglass mat tissue perform in terms of moisture vapor resistance?

- Fiberglass mat tissue is generally effective at resisting moisture vapor. It acts as a barrier, preventing the passage of water vapor and making it suitable for moisture control in applications like roofing and insulation. To enhance the moisture vapor resistance of fiberglass mat tissue, it can be combined with other materials like vapor barriers or moisture-resistant coatings. These additional layers provide extra protection against moisture infiltration, improving the overall performance of the fiberglass mat tissue. However, it should be noted that the moisture vapor resistance of fiberglass mat tissue can vary depending on factors such as thickness, density, and composition. Thicker and denser mats tend to offer higher resistance, while the presence of manufacturing additives or coatings can also affect the material's properties. In conclusion, fiberglass mat tissue is known for its moisture vapor resistance, but its performance may be influenced by various factors. It is recommended to consult product specifications or manufacturers' recommendations to determine the specific moisture vapor resistance of a particular fiberglass mat tissue product.

- Q: How does the width and length of fiberglass mat tissue affect its application?

- The width and length of fiberglass mat tissue can affect its application by determining how easily it can be cut and maneuvered during installation. A wider and longer mat tissue may provide better coverage on larger surfaces, reducing the need for multiple pieces and potentially saving time and effort. Additionally, the length of the mat tissue can influence its strength and stability, as longer fibers may provide better reinforcement properties. Ultimately, the choice of width and length should be based on the specific requirements of the application, such as the size of the area to be covered or the desired level of reinforcement.

- Q: Does fiberglass mat tissue provide any electrical insulation?

- Yes, fiberglass mat tissue does provide electrical insulation. It is commonly used as a reinforcement material in electrical applications due to its high dielectric strength and insulating properties.

Send your message to us

Fiberglass Mat Tissue Spray Up Roving with Fiberglass Gun Roving

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords