Fiberglass Mat Tissue Woven Roving for FRP Pipe Production

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of woven roving Description

1,high strenth,corosion and resistence

2,consistent thickness,no fuzz

3,rapid impregnating

4,ISO9001:2008

Glass woven rovings are bidirectional fabric by direct rovings in plain weave pattern. They are

applicable for hand lay-up,

winding and compress molding process, suitable for manufacturing tank, boat, automobile parts

and other FRP products.

Main Features of the woven roving

Consistent thickness and excellent surface treatment.

Rapid impregnating and good compatibility with resin.

Uniform tension, high dimensional stability and making handing easy.

Good mechanical properties and high strength of parts.

ISO9001 certificated

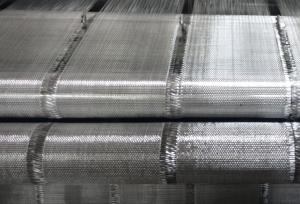

Woven roving Images

Woven roving Specification: weight& thickness

100 | 0.11 | |

135 | 0.14 | |

200 | 0.18 | |

290 | 0.23 | |

330 | 0.25 | |

350 | 0.28 | |

400 | 0.31 | |

600 | 0.52 | |

800 | 0.71 |

FAQ of woven roving:

Delivery Detail: 15-21days

Other spec. can be custom made as per customer's request.

Welcome to contact us for details!

- Q: Can fiberglass mat tissue be used for soundproofing?

- Yes, fiberglass mat tissue can be used for soundproofing. Fiberglass is known for its excellent sound absorption properties. When used as a mat or tissue, it can effectively reduce noise transmission by absorbing and dampening sound waves. The porous nature of fiberglass allows it to trap and dissipate sound energy, making it an ideal material for soundproofing applications. Additionally, fiberglass is lightweight, flexible, and easy to install, making it a practical choice for soundproofing projects.

- Q: Can fiberglass mat tissue be used for reinforcing fiberglass roofs?

- Indeed, fiberglass mat tissue is a suitable option for reinforcing fiberglass roofs. Comprised of delicate fibers that are joined together using a binder, fiberglass mat tissue is a thin and lightweight material. It is widely utilized as a reinforcement layer in fiberglass composites, providing them with robustness and endurance. Concerning fiberglass roofs, fiberglass mat tissue can be applied as an extra layer to enhance the roof's structural integrity. This additional layer aids in evenly distributing the load across the surface, thereby augmenting the roof's resistance against cracks, leaks, and other types of damage. Typically, fiberglass mat tissue is used alongside other fiberglass products, including resin and fiberglass cloth, to generate a sturdy composite material. The mat tissue is placed atop the fiberglass cloth prior to the application of resin. Subsequently, the resin saturates the mat tissue, establishing a bond between the layers. This combination results in a reinforced fiberglass roof that possesses heightened strength and durability. Moreover, fiberglass mat tissue can confer thermal insulation properties to the roof, contributing to temperature regulation and reduced energy consumption. It exhibits resistance against heat transfer, thereby preventing excessive heat accumulation within the building during hot weather. All in all, fiberglass mat tissue is an exceptional choice for reinforcing fiberglass roofs. By adding strength, durability, and thermal insulation properties to the roof, it becomes a reliable option for both residential and commercial buildings.

- Q: Does fiberglass mat tissue require any special handling precautions?

- Yes, fiberglass mat tissue does require special handling precautions. It is important to wear appropriate protective gear such as gloves, goggles, and a respirator when working with fiberglass mat tissue to prevent skin, eye, and respiratory irritation. Additionally, it is recommended to work in a well-ventilated area to minimize exposure to fiberglass particles.

- Q: How does the weight of fiberglass mat tissue affect its performance?

- The weight of fiberglass mat tissue directly affects its performance as a lighter tissue allows for better flexibility and ease of handling, while a heavier tissue provides increased strength and durability.

- Q: Can fiberglass mat tissue be used for reinforcing fiberglass pools?

- Fiberglass mat tissue is indeed suitable for reinforcing fiberglass pools. This product, known for its thin and flexible nature, is widely utilized in the construction and repair of fiberglass structures, including pools. Comprising delicate glass fibers bonded together with a binder, the mat tissue offers added strength and reinforcement when applied to the pool's surface. By doing so, it effectively prevents cracks and damage. Typically, it is used in conjunction with fiberglass resin, which acts as an adhesive to securely attach the mat tissue to the pool surface. The practice of utilizing fiberglass mat tissue for reinforcing fiberglass pools is widely adopted, as it significantly increases the pool's lifespan and durability.

- Q: How is fiberglass mat tissue used in the production of composite panels?

- Fiberglass mat tissue is used in the production of composite panels as a reinforcement material. It is typically placed between layers of resin to provide strength, stability, and impact resistance to the panel. The fiberglass mat tissue helps to distribute the load evenly across the composite structure, making it more durable and capable of withstanding various external forces.

- Q: Is fiberglass mat tissue resistant to moisture vapor transmission?

- Yes, fiberglass mat tissue is resistant to moisture vapor transmission. It is a highly durable and moisture-resistant material that is commonly used in various applications where moisture control is important, such as in roofing, insulation, and flooring. The fiberglass mat tissue is specifically designed to prevent the transmission of moisture vapor, helping to maintain the integrity and performance of the materials it is used with. Its resistance to moisture vapor transmission makes it an ideal choice for environments where moisture control is critical.

- Q: Are there any specific certifications or standards that fiberglass mat tissue must meet?

- Yes, fiberglass mat tissue must meet specific certifications and standards. These can include ASTM International standards such as ASTM D7055 for fiberglass mat used in roofing applications or ASTM C1667 for fiberglass mat used in gypsum panels. Additionally, the product may need to comply with industry-specific certifications like ICC-ES for construction materials or UL for fire resistance. Meeting these certifications and standards ensures the quality and performance of fiberglass mat tissue in various applications.

- Q: Does fiberglass mat tissue require any special tools for installation?

- Special tools may be needed for installing fiberglass mat tissue. These tools may include a utility knife or scissors for cutting the mat to the desired size, a roller or brush for applying adhesive or resin to secure the mat to the desired surface, and safety equipment like gloves and goggles to protect the installer from potential dangers. Furthermore, certain installations may necessitate the use of a heat gun or torch to activate or cure the resin. To ensure proper installation and ascertain if any special tools are necessary, it is crucial to carefully read and adhere to the manufacturer's instructions and recommendations for the specific fiberglass mat tissue being used.

- Q: Is fiberglass mat tissue suitable for agricultural applications?

- Yes, fiberglass mat tissue is suitable for agricultural applications. It is a versatile material that offers several benefits for use in the agricultural industry. Fiberglass mat tissue is resistant to moisture, chemicals, and UV radiation, making it ideal for applications such as greenhouse roofing, animal enclosures, and agricultural equipment. It provides excellent insulation properties, helping to regulate temperature and protect crops or livestock from extreme weather conditions. Additionally, fiberglass mat tissue is lightweight, easy to install, and durable, making it a cost-effective choice for agricultural projects. Overall, fiberglass mat tissue is a suitable material for various agricultural applications, offering durability, versatility, and protection for the farming industry.

Send your message to us

Fiberglass Mat Tissue Woven Roving for FRP Pipe Production

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords