Hot-Dip Galvanized Steel Roof of High Quality with Different Surface Traetment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

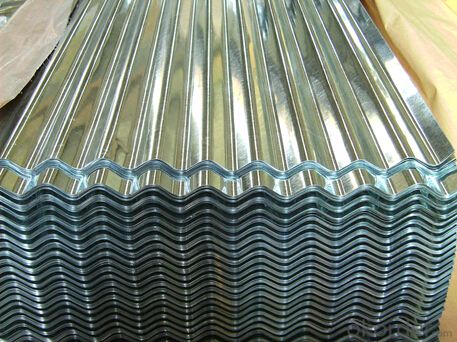

1. Hot-Dip Galvanized Steel Roof Description:

Hot-dip galvanized steel roof are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial application.

2.Main Features of the Hot-Dip Galvanized Steel Roof:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

3.Hot-Dip Galvanized Steel Roof Images

4.Hot-Dip Galvanized Steel Roof Specification

Material: Galvanized Sheet

Width: 650/800/890/900

Length: 1500/1800/2000/2400/3005/3600 or customized

Thickness: 0.2-2.0

Surface Treatment: Hot dipped/Bended

Application: warehouse; shelter; Commercial facilities; industrial facilities

5.FAQ of Hot-Dip Galvanized Steel Roof

Which payment term we can do?

L/C at sight or T/T.

What’s the basic material of this product?

Galvanized/Aluzinc Steel

What’s the coating composition of Hot-Dip Galvanized Steel Coil?

The coating composition is 55% aluminium in weight ratio, 43.4% zinc, and 1.5% silicon, with excellent corrosion and heat resistance performance.

- Q: What are the different surface treatments applied to steel coils?

- Some of the different surface treatments applied to steel coils include galvanizing, which involves coating the steel with a layer of zinc to protect it from corrosion, painting or powder coating to enhance the aesthetics and provide additional protection, and passivation to remove any impurities on the surface and improve its corrosion resistance.

- Q: How are steel coils protected during transportation?

- Steel coils are kept safe and free from harm during transport through a range of precautionary measures. One widely used technique involves utilizing top-notch packaging materials like heavy-duty plastic wrap or waterproof paper. These materials form a protective shield against external factors such as moisture, dust, and debris. Moreover, steel coils are typically placed on wooden pallets or skids to elevate them from the ground and prevent direct contact with surfaces that may cause scratches or dents. To provide further protection, the coils are securely fastened to the pallets using strong, corrosion-resistant metal strapping or bands. This ensures that the coils remain in position and do not shift or move during transport, significantly reducing the risk of damage. Additionally, specialized equipment like coil cradles, coil racks, or coil bunks are used to load and secure the steel coils onto flatbed trailers or shipping containers. These devices are specifically designed to firmly hold the coils in place and evenly distribute their weight, preventing any stress or strain during transit. Apart from physical safeguards, steel coils may also undergo various surface treatments before being transported to prevent corrosion. This may involve applying a protective coating or oiling the coils to create a barrier between the steel and the surrounding environment. This process is particularly important when the coils are exposed to adverse weather conditions or long shipping durations, as it helps to prevent rust or other forms of corrosion. In conclusion, a combination of appropriate packaging, secure fastening, and proper loading techniques are employed to ensure the safety of steel coils during transportation. These measures guarantee that the coils arrive at their destination without significant damage.

- Q: i see a lot of connexes say repair only with corten steel. what is the difference between corten steel and regular steel. and if i was going to stick weld it what type of electrode would i use?and while i'm at it what is the best electrode to use when welding galvenized steel?

- 6010 and 6011 Electrodes for welding galvenized steel. Weathering steel, best-known under the trademark COR-TEN steel and sometimes written without the hyphen as Corten steel, is a group of steel alloys which were developed to obviate the need for painting, and form a stable rust-like appearance if exposed to the weather for several years. The corrosion-retarding effect of the protective layer is produced by the particular distribution and concentration of alloying elements in it. The layer protecting the surface develops and regenerates continuously when subjected to the influence of the weather. In other words, the steel is allowed to rust in order to form the 'protective' coating. For welding corten steel: 1A.W.S ClassificationE 7018 - 1AWS A 5 - 1 - 78 2IS classificationE 5424 JXIS 814 (Part I II)H 3BS classificationE 51.54 B 12 17HBs 639 - 1976

- Q: How are steel coils used in the manufacturing of agricultural trailers?

- Steel coils are used in the manufacturing of agricultural trailers as they provide strength and stability to the trailer's structure. These coils are typically shaped and welded to form the trailer's frame, ensuring durability and load-bearing capacity. Additionally, steel coils can be used to reinforce certain components of the trailer, such as the axles or suspension system, to enhance its overall performance and withstand the demands of agricultural work.

- Q: I am buying a knife for my future husband for his wedding gift and I was wondering what is better carbon steel or stainless steel?

- The better grade of stainless is the top choice, but it can be hard to find, and expensive. - Surgical scalpels are made of it. (Common '420' stainless will not hold an edge as well as high carbon steel.)

- Q: What are the different methods of forming steel coils?

- Steel coils can be formed using several methods, depending on their specific requirements and applications. These methods comprise hot rolling, cold rolling, and continuous casting. The most commonly used method for forming steel coils is hot rolling. This involves heating the steel billet or ingot to high temperatures and passing it between a series of rollers to reduce its thickness and shape it into a coil. Typically, this process is carried out above the recrystallization temperature of the steel, which allows for better shaping and improved mechanical properties. On the other hand, cold rolling is performed at or near room temperature. It entails passing the steel through a series of rollers to reduce its thickness and shape it into a coil. Cold rolling is often utilized to produce steel coils with precise dimensions and excellent surface finish. Additionally, it can enhance the strength and hardness of the steel. Another method for forming steel coils is continuous casting. This involves pouring molten steel into a continuous casting machine, where it solidifies into a strand. The strand is then continuously fed into a series of rollers, which shape it into a coil. Continuous casting offers several advantages, including improved efficiency, reduced energy consumption, and better control over the steel's composition and quality. In addition to these primary methods, there are various secondary processes involved in forming steel coils. These processes encompass pickling, annealing, and coating. Pickling is used to remove any rust or scale from the surface of the steel, ensuring a clean and smooth finish. Annealing involves heating the steel to a specific temperature and then slowly cooling it, which improves its ductility and reduces internal stresses. Coating is often applied to steel coils to provide corrosion resistance or enhance its aesthetic appeal. To summarize, steel coils can be formed using different methods such as hot rolling, cold rolling, and continuous casting. Each method offers distinct advantages and is chosen based on the specific requirements of the steel product. Additionally, secondary processes like pickling, annealing, and coating are employed to further enhance the quality and performance of the steel coils.

- Q: I am doing a experiment on mild steel soaked in sodium chlorideanyone can enlighten me about the effect of the sodium chloride in engineering term ?The mild steel specimen which I soaked in the sodium chloride has orange rust on it

- The mild steel contains a lot of Iron. The NaCl solution quickly attacks the iron content and forms rust. Over time, the solution may also cause what is called 'Chloride Cracking' of the steel. Pitting corrosion of stainless steel due to chlorides would certainly produce a rust-colored product. Passivation can be used to maintain a good corrosion resistant surface of stainless steel process vessel. There are many commercial products for this purpose. In the pharmaceutical industry, this process is often called derouging, that is to remove the buildup of iron oxides on the stainless steel process surfaces

- Q: Hey do you know what is Steel Arch Building and how it looks like exactly??

- Typically, okorder /

- Q: What is the process of recycling steel coils?

- To ensure optimal utilization of material and minimize waste, several steps are undertaken in the recycling of steel coils. To begin, steel coils are gathered from a variety of sources, including industrial manufacturing facilities, construction sites, and scrap yards. These coils are then transported to a recycling facility where their quality is thoroughly assessed and the appropriate recycling method is determined. Following this, the steel coils are cleansed to eliminate any contaminants such as dirt, oil, or paint. This cleansing process may involve the use of chemical agents or mechanical procedures, depending on the extent of contamination. The cleansing of the coils is crucial in maintaining the quality of the recycled steel. After the cleansing process, the coils are either shredded or sheared into smaller pieces for easier processing. This step helps to increase the surface area, making it simpler to separate the steel from any other materials that may be present within the coils. Once the coils have been broken down into smaller pieces, they undergo magnetic separation. This entails passing the steel pieces through a magnetic separator that utilizes powerful magnets to attract and separate the ferrous steel from non-ferrous materials like aluminum or plastic. This separation is vital in ensuring the purity of the recycled steel. The separated steel pieces are then subjected to extremely high temperatures in a furnace, causing them to melt. This melting process not only eliminates any remaining impurities but also allows the steel to be shaped into various forms and molds, depending on its intended use. Following the melting process, the molten steel is poured into molds or cast into ingots to solidify. These ingots can be further processed and transformed into new steel products or used as raw material in different industries. Throughout the recycling process, the steel coils are subjected to quality control measures to guarantee that the resulting recycled steel meets the necessary specifications and standards. This includes conducting chemical analyses and mechanical tests to verify the strength, composition, and overall quality of the recycled steel. In conclusion, the recycling of steel coils involves the collection, cleansing, shredding, separation, melting, and molding of the steel to produce new products or raw material. This process not only conserves valuable resources but also reduces the environmental impact associated with traditional steel production.

- Q: What are the cost considerations when purchasing steel coils?

- When buying steel coils, there are several factors to consider regarding cost. To begin with, the price per unit of steel coil is a significant consideration. The cost of steel coils can vary depending on factors such as the type of steel, grade, thickness, width, and length. Higher-grade steel coils tend to be more expensive than lower-grade ones, and thicker or wider coils can also come at a higher cost. Another cost consideration is the quantity of steel coils required. Purchasing larger quantities often comes with volume discounts, so it is important to determine the necessary quantity and assess whether it is more cost-effective to buy in bulk or smaller batches based on demand and storage capacity. Transportation costs should also be taken into account. The weight and size of the coils can impact shipping costs, especially for long-distance transportation. Additionally, the distance between the supplier and the buyer can affect freight charges, so it is crucial to evaluate different shipping options and choose the most cost-effective method. Furthermore, it is essential to consider any additional costs associated with processing or customizing the steel coils. For example, if the coils need to be cut, leveled, or coated, these extra services can add to the overall cost. Obtaining quotes from different suppliers and comparing prices for these value-added services is important. Lastly, the overall quality and reliability of the steel coils must be taken into consideration. Although cheaper options may seem more cost-effective initially, they may end up costing more in the long run if they do not meet required standards or have a shorter lifespan. Choosing reputable suppliers with a history of delivering high-quality products is advisable to ensure that the investment in steel coils is worthwhile. In conclusion, the cost considerations when purchasing steel coils include the price per unit, quantity discounts, transportation costs, additional processing services, and the overall quality and reliability of the coils. Thoroughly evaluating these factors will help make an informed decision that balances cost-effectiveness with the desired quality and specifications of the steel coils.

Send your message to us

Hot-Dip Galvanized Steel Roof of High Quality with Different Surface Traetment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords