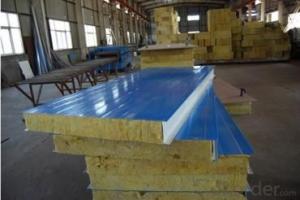

Rockwool Sandwich Panel 950/Sheet Metal Prices

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

Packaging Details:Standard seaworthy packing.

Delivery Detail:20days after your deposits

Presentation

1.Heat Insulating

2.Good Fire Resistance

3.Width:950mm,1150mm

4.ISO9001and ISO14001 certification

5.Widely use

Features:

1. Good Thermal Insulation, an energy saving material

2. Good Fire Resistance: B1 grade for total panel

3. Special Connection Design: Screw concealed connection

4. Graceful Finish: embossment, small wave, big rib and flat finish

5. Advance Machine: The longest main machine

6. Strict Workshop Management: TMP-5S management system

7. Raw Material: Only quality steel is selected.

8. Strict Quality Control: ISO9001and ISO 14001 certification

9. Wide Usage: Used as roof and wall in workshop and warehouse

Application:

Because of its excellent thermal insulation and good fire proof property, it is widely used as roof and wall in workshop and warehouse.

Specification:

Item

Thickness of facing plate

Type of Core Material

Thickness of core material(mm)

Width(mm)

Wall Panel

0.3-0.6mm

EPS/rock wool/glass wool/PU

50/75/100/150/200

950/1150

Roof Panel

0.3-0.6mm

EPS/rock wool/glass wool/PU

50/75/100/150/200

950/980

The width of the pu sandwich panel: 930mm/1000mm

- Q: Can steel sheets be used for food processing equipment?

- Yes, steel sheets can be used for food processing equipment. Stainless steel is a popular choice for food processing equipment due to its durability, corrosion resistance, and ease of cleaning. It is non-reactive with food and does not impart any unwanted flavors or odors. Steel sheets can be formed into various shapes and sizes, making them suitable for different types of food processing equipment such as mixers, conveyors, tanks, and cutting blades. Additionally, stainless steel is also resistant to high temperatures, making it ideal for applications that involve heat. Overall, steel sheets are a reliable and hygienic material choice for food processing equipment.

- Q: What are steel sheets?

- Steel sheets are flat metal plates made of steel that are used in various industries for applications such as construction, manufacturing, and fabrication. They are typically thin and come in different sizes and thicknesses, making them versatile for a wide range of purposes.

- Q: Do steel sheets have any magnetic properties?

- Yes, steel sheets do have magnetic properties. Steel is an alloy composed primarily of iron, carbon, and other elements, and it is known to be ferromagnetic. This means that it can be magnetized and attracts magnets. However, the degree of magnetism in steel can vary depending on its composition and processing. Some steel alloys can be easily magnetized and retain their magnetism even after the applied magnetic field is removed, while others may have lower magnetic properties. The presence of impurities and the specific heat treatment process can also affect the magnetic properties of steel. Overall, steel sheets can exhibit magnetic properties, but the degree of magnetism may vary depending on the specific type and composition of the steel.

- Q: What is the standard size of a steel sheet?

- The standard size of a steel sheet can vary depending on its intended use and industry standards. However, common sizes for steel sheets range from 4x8 feet to 5x10 feet.

- Q: Can steel sheets be recycled?

- Yes, steel sheets can be recycled. Steel is a highly recyclable material and can be reprocessed into new steel products without losing its quality. Recycling steel sheets helps to conserve natural resources, reduces energy consumption, and minimizes waste sent to landfills.

- Q: How are steel sheets tested for hardness?

- Steel sheets are typically tested for hardness using a method called the Rockwell hardness test. This test involves applying a specific amount of force onto the steel sheet's surface using a diamond or hardened steel ball indenter. The depth of indentation created by the indenter is measured, which provides a hardness value on the Rockwell scale.

- Q: What is the average moisture resistance of steel sheets?

- The average moisture resistance of steel sheets can vary depending on various factors such as the type of steel, the coating or treatment applied, and the specific environmental conditions. However, steel sheets are generally known to have good moisture resistance due to their inherent corrosion-resistant properties.

- Q: What are the electrical conductivity properties of steel sheets?

- Steel sheets have high electrical conductivity properties due to the presence of metallic bonds between iron atoms, allowing for the easy flow of electric current through the material.

- Q: Can steel sheets be used for safety barriers or guardrails?

- Yes, steel sheets can be used for safety barriers or guardrails. Steel sheets are often used in the construction industry for their strength, durability, and ability to withstand impact. They can be shaped into various configurations to create safety barriers or guardrails that provide protection and prevent accidents. Steel sheets are commonly used in road safety barriers, highway guardrails, and industrial safety barriers. They are designed to absorb the impact of a collision, redirect the vehicle, and prevent it from crossing into oncoming traffic or hazardous areas. Additionally, steel sheets can be galvanized or coated to enhance their corrosion resistance, making them suitable for outdoor applications where they may be exposed to harsh weather conditions. Overall, steel sheets are a popular choice for safety barriers and guardrails due to their robustness and reliability in providing protection.

- Q: Are steel sheets available in textured finishes?

- Yes, steel sheets are available in textured finishes. Textured finishes can be achieved through various processes such as embossing, etching, or brushing. These techniques create patterns or textures on the surface of the steel sheet, giving it a unique and visually appealing appearance. These textured finishes not only enhance the aesthetic appeal of the steel sheet but also provide functional benefits like improved grip, reduced glare, or increased durability. Different types of textures can be applied to steel sheets to suit different applications and design preferences.

Send your message to us

Rockwool Sandwich Panel 950/Sheet Metal Prices

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords