Construction Metal Board Rockwool Sandwich Panel 50mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Quality Polyurethane Sandwich Panels for Roof,Wall and Cold Storage

1.Structure of Sandwich Panel

Sandwich panel is composed of 2 layers of weather-proof colored steel sheets and jetted the hard forms of polyurethane between 2 layers which feature fireproof materials. Sandwich panel is suitable for the various roofs and walls referring to the large-size factory buildings, storages, exhibition halls, gymnasiums, freezing stores, purifications workshops, etc, Sandwich panel has features temp-keeping, heat insulation, weight-bearing, weatherproof with the rich colorfulness and good appearance.

2.Main Features of the Sandwich Panel

1) Our EPS sandwich panel has the following characteristics:light dead weight, high mechanical strength, excellent shearing resistant performance, strong corrosion resistance, high durability, and weather fastness, etc.

2) The sandwich panel has excellent insulating performance: heat insulation, sound insulation, waterproof performance, etc.

3) It is easy to install and can be used many times over.

4) Nowadays, the EPS sandwich panel is widely used for cleaning workshops, industrial factory buildings, office buildings, stadiums, villas, and public buildings, etc.

5) Apart from EPS sandwich panels, Wiskind also offers rock wool sandwich panels, glass wool sandwich panels, PU sandwich panels, honeycomb sandwich panels.

6) These products have all passed ISO9001 and ISO14001 certification. Due to their high quality and low price, they are well received by our customers in Russia, Australia, Angola, Congo, and Korea, etc.

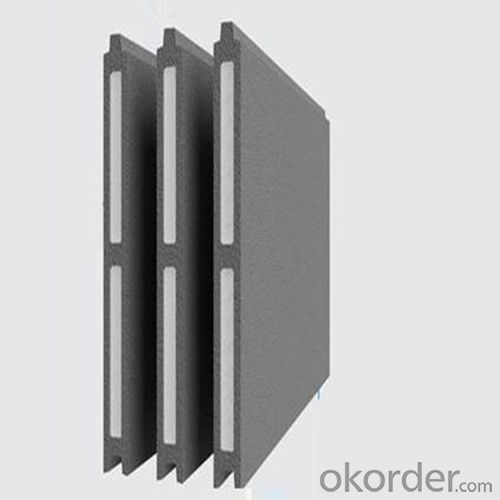

3. Sandwich Panel Images

4. Sandwich Panel l Specification

Effective width Wall panel: 950mm 1150mm 1200mm Roof panel: 950mm 980mm

Length; According to customer's request

Materials; Polystyrene foam board(EPS), Color steel sheet

Structure; Upper and lower layer: Color steel sheet

Middle; polystyrene foam board

Thickness; Color steel sheet: 0.3-0.6mm

Polystyrene foam board: 50mm 75mm 100mm 150mm 200mm

The polystyrene density; 8-20kg/m3

Conventional color; RAL standard

Character; Light in weight, heat insulation, water resistant, green and environmental

Use various roofs and walls referring to the large size factory buildings, storages, exhibition halls, gymnasiums etc.

5.Advantages of Sandwich Panels

1) Heat and sound insulation: The outer steel sheets can maintain the lastingness of the color of the building, and reduce the solar radiation and keep the appropriate indoor temperature. The high quality heat insulation materials are made with the adoption of polyurethane PU and (PIR) polyisocyanurate resin acid hydrogen containing no Chloro-fluoro-carbons (CFC).

2) A degree inflaming retarding: This system can effectively prevent the fire and prevent the fire from spreading during the cross construction and during the use of the boards

3) Environment protection: By learning after the successful experience in environment protection constructions from companies home and abroad and through our scientific analysis, we objectively bear the idea of “low carbon designing, environmental building materials and energy-saving technology” in mind.

4) Super-low heat conductivity: The lowest heat conducting coefficient of the heat insulation boards ensures that, under the condition that the thinnest heat insulation materials are used; the system can meet the energy-saving requirement and offer the strongest basic guarantee to meet the requirement of high standard heat insulation

5) Easily and quick installation

6.FAQ

1) How to guarantee the quality of the products?

2) We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3) How long can we receive the product after purchase?

4) In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: Can Caoyan sandwich wall be installed? How to install Thank you

- Can ah, with steel structure

- Q: Is polystyrene sandwich board flammable?

- Conventional flat polystyrene polystyrene sandwich panels are non-flame retardant, there is a Hongxin source flame retardant polystyrene sandwich panels, but relatively less flame retardant effect such as rock wool and other core material sandwich panels , And now fire requirements are not allowed to use polystyrene sandwich panels

- Q: anxious! Will the polyurethane sandwich panels of various parameters, plant design!

- Polyurethane is a two-component AB material (isocyanate and combined polyether) mixed foam, is the thermal insulation material in the lowest thermal conductivity of 0.017 ~ 0.024 (thermal conductivity of the lower the better insulation). Polyurethane sandwich panels used in the filling process of polyurethane, pre-made pre-insulation board directly installed on-site use. If your plant area is relatively large, it is recommended that you only use the whole color plate, and then use the field of polyurethane spray foam process, this process than the infusion process is the advantage of spraying seamless, better insulation. The cost is still lower than the infusion process.

- Q: Flour mill production workshop, steel frame, roof with glass wool cotton sandwich panel (veneer) whether it can,

- I can answer; I can not use color steel to answer;

- Q: What is the latest export tax rebate rate for sandwich panels and color steel tiles? Thank you

- 3921199000 Other foam sheets, sheets, films, foils, strips Tax rebate rate 13% No regulatory conditions 7210700000 painted or coated iron or non-alloy steel wide sheet (width ≥ 600mm) Tax rebate rate 13% No regulatory conditions

- Q: I need to install a circuit breaker and a few outlets on a container made with sandwich panels.Are there any special equipments or materials for the job?

- You will need to use surface mount materials that can be screwed or bolted to the sandwich panels. Most electrical distribution centers have surface mounting options. For wiring, you will need to use conduit (PVC, EMT, or flex), metal clad cable, or wire mold. Surface mount junction boxes for devices need to be compatible with your choice of wiring method.

- Q: Sandwich board formaldehyde excessive fine how much

- Homemade materials in the toxic substances is an important source of indoor air pollution, and even some people because of building materials is not up to suffering from leukemia. The maximum allowable concentration of formaldehyde in the room air is 0.08 mg / m3. National furniture standard GB5296.2004 provides that: if the formaldehyde emission is greater than 1.5 mg / l of the required standards, the manufacturers will be punished with sales of 50% to 3 times the fine. Will also be subject to fraudulent penalties. Operators can not sell wood-based panels without production licenses. In accordance with the relevant laws and regulations, sales of no production license of the wood-based panel operators will be punishable by a fine of 50,000 yuan to 20 million, if you are selling a production license of the man-made board was fine, you do not have the quality of the product Joint liability, manufacturers should be fine, but this money or Trade and Industry Bureau or to punish you, you can rely on the Trade and Industry Bureau of the test report manufacturers claim compensation, if he does not pay, you can sue him.

- Q: Does anyone know the reason why the sandwich panel is bubbling and partially degumming during the pressing process?

- Hydraulic press to suppress the plate, the bubble and local degumming these two phenomena are due to: 1, veneer moisture content is too high or dry uneven 2, the amount of glue is too large 3, buck faster or hot pressing temperature is too high 4, the degree of condensation is not enough resin 5, hot pressing time is insufficient

- Q: Polyurethane sandwich panels in the polyurethane is what material, what are the benefits of industrial building materials should choose polyurethane?

- Polyurethane is a two-component AB material (isocyanate and combined polyether) mixed foam, is the thermal insulation material in the lowest thermal conductivity of 0.017 ~ 0.024 (thermal conductivity of the lower the better insulation). Polyurethane sandwich panels used in the filling process of polyurethane, pre-made pre-insulation board directly installed on-site use. If your plant area is relatively large, it is recommended that you only use the whole color plate, and then use the field of polyurethane spray foam process, this process than the infusion process is the advantage of spraying seamless, better insulation. The cost is still lower than the infusion process.

Send your message to us

Construction Metal Board Rockwool Sandwich Panel 50mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 8000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords