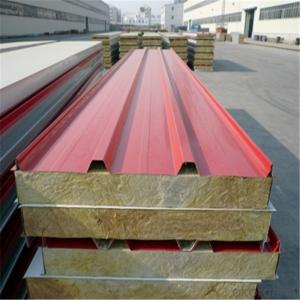

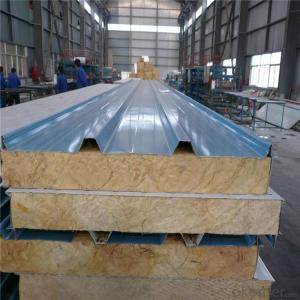

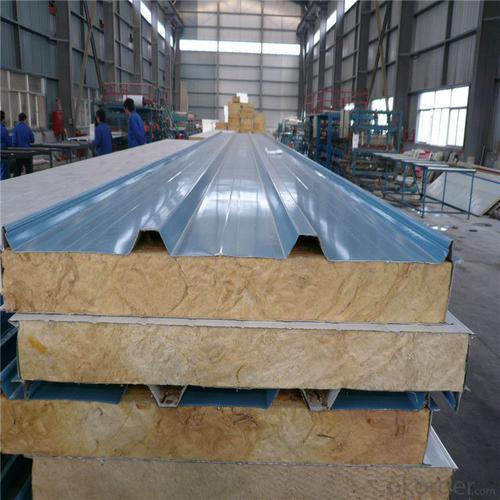

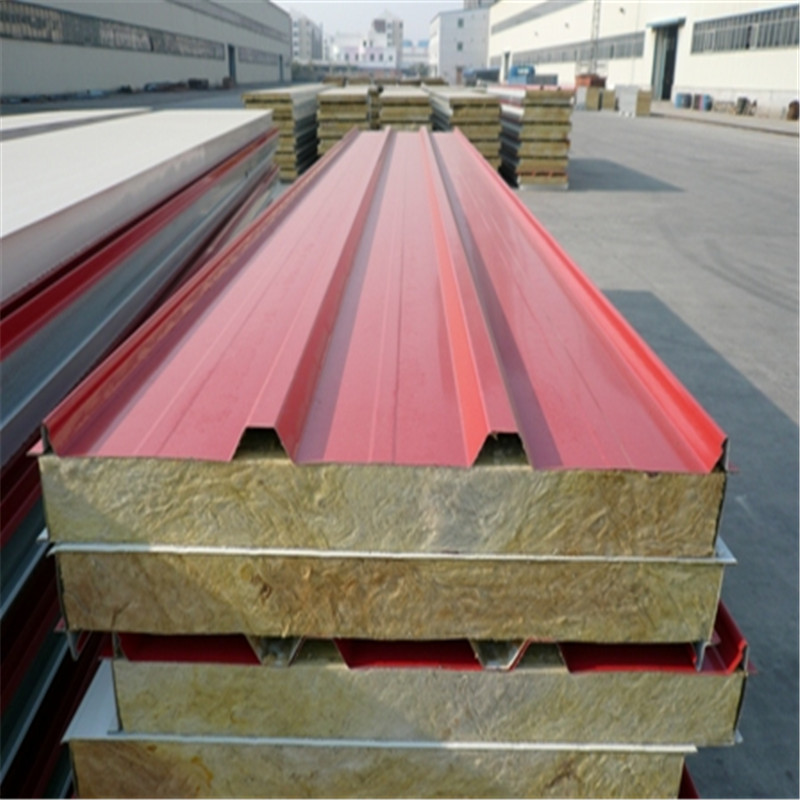

Rock wool sandwich panels for low cost wall cladding and roof of prefabricated house

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Rock wool sandwich panels for low cost wall cladding and roof of prefabricated house

Description of rock wool sandwich panels:

The rock wool, which we call it “mineral wool”, is made from blast furnace slag, phosphorus slay, and coal ash through fusion. This is unreal rock wool with the features of high slag and has a lot of dust.

Rock Wool Sandwich Panel advantages

For more than ten years, sandwich panels with rock wool cores have been used successfully in a quick way of construction, having lots of advantages compared to conventional building systems:

Fast installation and convenient handling

Crane assembly and no scaffolding required

No thermal bridges and good thermal insulation properties

Plenty of design with choice of profiles and colours

Panels can be installed horizontally or vertically

Reliable robust mechanical performance

Outstanding non-combustible and acoustic performance

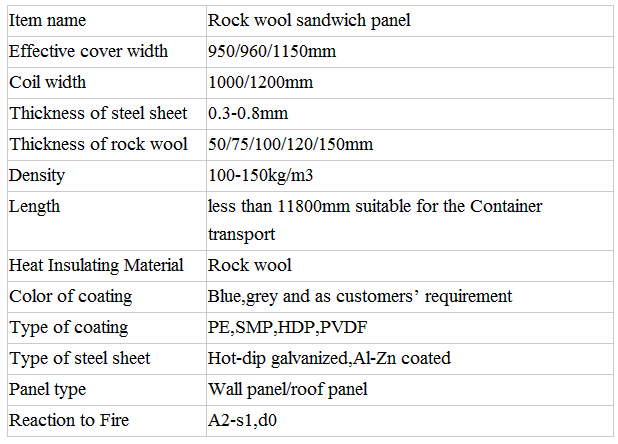

Specification of rock wool sandwich panels:

Applications

Rock Wool Sandwich panels cover all applications in steel building construction and prefabricated houses: external walls, roofs, partitions, ceiling panels, fire rated and acoustic sandwich panels for workshops,warehouse, industrial factory buildings, office buildings, stadiums, villas, and public buildings, etc.

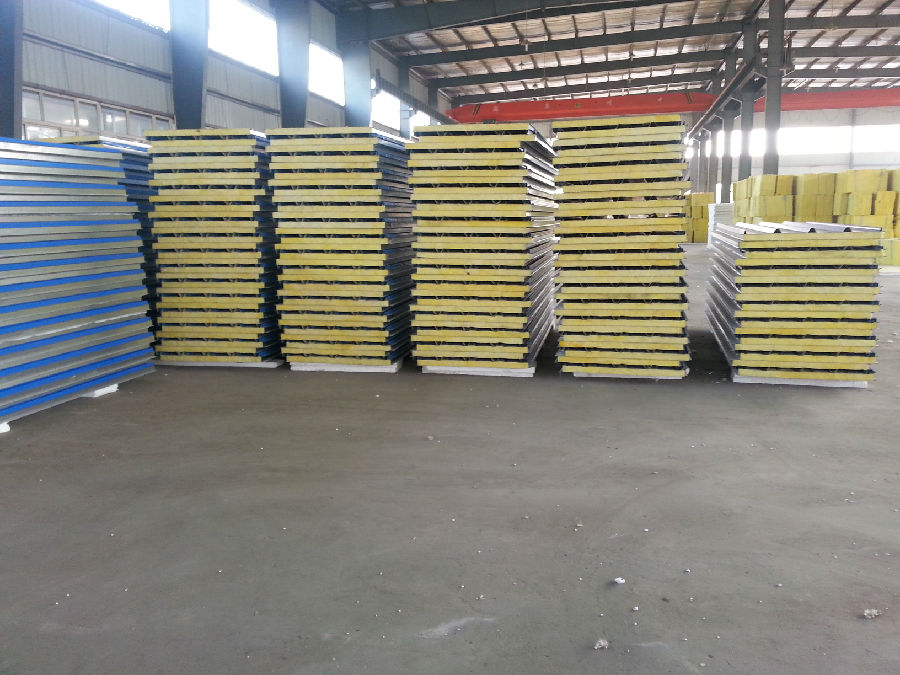

Workshop of rock wool panels

- Q: Color steel sandwich panels are prefabricated or on-site production processing

- Not prefabricated, is custom production.

- Q: Everybody is the polyurethane sandwich board to which manufacturers to buy?

- I came to tell you that I was buying polyurethane sandwich panels to go to Zhejiang Bo Ya building materials, where their products are not only durable, good quality, but also beautiful, there are a variety of styles, all kinds of places can be used on the

- Q: There is a comprehensive building, a two-story canteen, three-story activity room, the roof for the Caigang sandwich panel roof, the building fire rating for the two, the roof sandwich board design using polystyrene foam sandwich panels can?

- Can not. Polystyrene foam sandwich panels are mostly flammable and flammable, preferably flame retardant, and the burning properties of their materials do not meet the requirements of Grade II refractory grade buildings. Our province has been a few cases of Caigang sandwich panel roof fire cases, due to sandwich material led to the rapid expansion of fire.

- Q: Sandwich board machine how much money

- I am the production of color plate machine, and hope to cooperate with you, OKorder Zhongji machinery Yang Yun

- Q: I would like to use Caigang sandwich panels to do the indoor ceiling ... how to use what keel .. how the ceiling thank you

- Swallowtail screws (also known as drilling screws) is a color plate dedicated screws, thousands of square meters of large factories are fixed with how it will be unstable, light steel keel is absolutely not work.

- Q: Magnesium Sulfide sandwich color steel plate

- Henan Ming-chen purification Technology Co., Ltd. mainly produces and sells magnesium sulfate fire board, magnesium sulfide mechanism board, magnesium sulfide manual board, purification equipment (return window, diffuse board, medicine cabinet, purification lamp, color steel plate series, Purification of special aluminum, plate exhaust, residual pressure, air conditioning units, ozone generator, efficient air supply, air filter, laminar flow hood, clean sampling vehicles, transfer window, air self-purification, air shower), to undertake purification engineering. I uphold the company in good faith-based, quality-oriented, service-oriented concept for the majority of customers to provide quality services.

- Q: Sandwich board is 50,75,100,150, color steel thickness, casually one can.

- 50 thick: 45 ~ 75 yuan 75 thick: 53 ~ 87 yuan 100 thick: 62 ~ 95. Sandwich panel thickness is not limited. I am also about this. Because you are not very clear.

- Q: Pressure-type sandwich color plate thickness 100mm What is the socket type

- In general, this type of plug-in, such as Heilongjiang, Czech Republic, the European-style rock wool board has plug-in.

- Q: Span 13 meters of the roof beam how to do the roof with 75mm foam sandwich board does not consider the wind load (indoor)

- We have a home here Jiangxi Baoyuan Caigang, they specializing in the production of sandwich panels, activities, color steel tiles, galvanized sheet, C steel, steel industry in the color of the very experienced, Jiangxi Baoyuan Caigang products sell well throughout the country , Won the majority of customers praise.

- Q: Sandwich board is used to do what ah ??

- Should be "sandwich board" was right. Sandwich panel products are composed of two layers of metal panels (or other material panels) and directly in the middle of the panel foam, mature molding of the composition of the polymer core insulation. These sandwich panels are easy to install, lightweight and efficient. Filling system is also used to close the molecular structure, you can put an end to the condensation of water vapor. The forming of the outer steel sheet takes into account the structural and strength requirements, and takes into account the appearance, the inner layer is formed into a flat plate to suit various needs. Sandwich panels for large industrial plants, warehouses, gymnasiums, supermarkets, hospitals, cold storage, activities, building plus layer, clean workshop and the need to heat insulation fire places.

Send your message to us

Rock wool sandwich panels for low cost wall cladding and roof of prefabricated house

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords