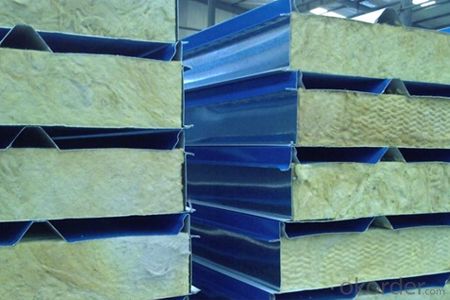

rockwool sandwich panel china sandwich panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

| Place of Origin: | China (Mainland) | Brand Name: | DESUMAN | Model Number: | sandwich panel price,DSM808 |

| Panel Material: | Metal | Type: | EPS Sandwich Panels | Thickness: | 50-200mm |

| Color: | Blue, White, Red etc | Length: | less than 11.8m | width for roof: | 960mm or 1050mm |

| width for wall: | 950mm or 1150mm | Steel thickness: | 0.3-1.5mm | Advantage: | energy saving, easy |

| Smaple: | for free |

Packaging & Delivery

| Packaging Detail: | PE film on the surface of panel, then put into container directly |

| Delivery Detail: | within 12 days after client confirm |

Specifications

1.Sound Insulation

2.Fireproof,

3. Anti-earthquake

rockwool sandwich panel china sandwich panel clean room

- Q: Bunny plate prices and Moganshan plate which is of good quality, expensive?

- The two almost, but I tend to king coconut plate, although he is also the top ten brands of plates, but the king coconut of the paint plate is the national standard drafting unit

- Q: What is the material of the deer river?

- Now the dew river almost marks the environmental protection, consumers take this brand, manufacturers also say that the dew river, true and false, can Mongolia Mongolia, or recognize the good.

- Q: How is the stone sheet transported?

- (2) the transportation of decorative stone sheet Handling and handling must comply with the following: (1) should be lightly loaded when handling, is strictly prohibited to roll, the vertical code must be placed on the back edge of the first landing. (2) stone sheet monolithic area of more than 0.25m2, all upright handling. Large products with lifting gear handling, the force edge edge must be pad. (3) wooden box packaging products, with lifting equipment loading and unloading, each lifting a box is appropriate. Cauline packaging products when handling, shall not pull grass rope. (4) loading code should be stored in accordance with the requirements of storage, transport required a smooth, non-collision.

- Q: Giant peak sheet in the end okay?

- Giant peak sheet is produced by Zhejiang Jifeng Wood Industry Co., Ltd., Zhejiang Jufeng Wood is the first batch of enterprises in Zhejiang Province to obtain green business and production license, Zhejiang is the largest production base of decorative plate substrate is well-known brand " Bunny "" Moganshan "decorative board substrate designated suppliers. Zhejiang Jufeng Wood Industry Co., Ltd. has been awarded the honorary title of China Environmental Labeling Product Certification, ISO9001 Quality Management System Certification, California Certification, China Famous Brand, Zhejiang Famous Brand, Zhejiang Famous Brand, Zhejiang Province Decoration Board Top Ten Brand Zhejiang Province forestry leading enterprises, agricultural enterprises in Zhejiang Province. In the environment-friendly decorative materials research and development and marketing has been in the industry-led, the product has reached F4 Star, E0, E1-class environmental standards. So, Giant peak sheet quality is absolutely no problem, with the bunny, Moganshan these qualities almost, may be in the brand publicity, Kyoho start late, but the quality is definitely OK!

- Q: Look at the brand of wardrobe quite nice but offer too high. So I would like to buy their own plate to find wood workers to do. What sheet is good?

- Fukuoka's joinery board. The The + Glue + wood line package edge + drawer track board with ordinary fire board can be a panel to see what you are the style of design, the color is light maple board ash, etc., heavy with teak, sandalwood, iron Knife, etc. If it is white, there are closed paint kerosene texture (no bad panel on the line) and semi-closed paint (the normal use of water texture is more beautiful)

- Q: E0 grade sheet and E1 grade plate, which is more environmentally friendly? How to distinguish

- E0 level is the European standard, e1 level is the domestic standard, e0 relatively strict implementation of the standard, which is commonly referred to as more environmentally friendly, but the so-called business e0 level is sometimes just a rhetoric, the best time to buy Look at the relevant files. Can not let its flicker.

- Q: What is the difference between wood and wood?

- Wood can be called wood logs is the original length to the size, shape, quality standards or special provisions cut into a certain length of the wood section, the wood section called logs. Wood is processed semi-finished products. The use of wood: to be divided into direct use and chemical or special processing to do the use of raw materials. Wood direct use are: construction, pit wood, pillars, sleepers, packaging, furniture, craft sculpture, ships, sports equipment, cultural and educational supplies, musical instruments, decoration, grenade handle, butt, After chemical processing or special processing to do the use of raw materials are: paper, rayon, regenerated cellulose, nitrocellulose, cellulose acetate, ethyl cellulose, hydroxy cellulose, phenyl cellulose.

- Q: Home decoration cabinet made with what plate is good? How is the Malacca plate?

- Malacca is a tropical tree species from Indonesia, the Philippines and other places. Malacca core has a lot of advantages, relatively smooth, relatively homogeneous wood, foreign splicing is good, after drying to the domestic processing after processing made Malacca ecological board more suitable for: home decoration, wardrobe and so on.

- Q: On the difference between Q235 and Q345 plate and use

- Q235 steel is an ordinary carbon structural steel, that the old A3 steel its yield point is 235MPa, tensile strength of 375-500MPa. General use more. Q345 steel is a low-alloy high-strength structural steel, including 16Mn, 12MnV, 14MnNb, 18Nb, 16MnRe, including a class of steel, the yield point of 345MPa, tensile strength of 470-630MPa. Ordinary quality of low alloy steel.

- Q: What is Guodong plate

- Guodong Group mainly produces medium density fiberboard, with an annual output of 300,000 cubic meters, widely used in furniture, wood flooring production. 2017 Guodong Group will add three new production lines from Germany, the production capacity will reach 100 million cubic meters or more, will become the largest domestic medium-density fiberboard manufacturing enterprises

Send your message to us

rockwool sandwich panel china sandwich panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords