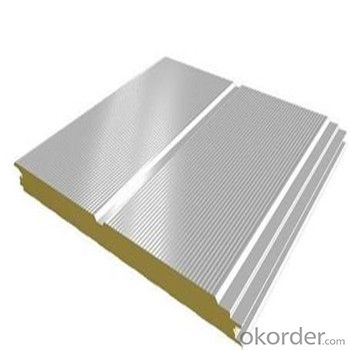

Insulated Sandwich Panels with Rockwool for Prefab House

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Wall Sandwich Panel with rockwool core

Advantage:1. fireproof

2. anti-dust

3. light in weight

4. economic and durable

5. heat and sound insulation

Basic Structure :

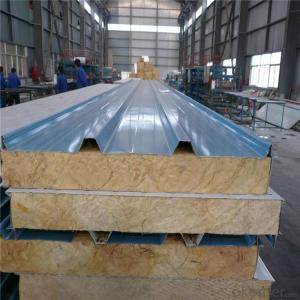

Rock Wool Sandwich Panels use fire-retardant rockwool as core material, and zinc-plated & color-coated steel sheets as the upper and bottom sheets. The panels

are formed by heating and pressing with high-intensity glue through high-speed continuous forming machines.

Detail introduction:

The Rockwool Sandwich Panel production process adopts the colored steel plate as surface board and the core materials is the self-extinguishing closed cell rock wool, it is kind of high –strength composited building materials, and it was formed in the automated continuous molding machine, by combining the pressed colored steel with high strength adhesives. Rockwool sandwich panels have the excellent fire performance because the color steel plate and rock wool materials are fireproof best.

Specification References:

Detailed Specification For Rock Wool Sandwich Panels | |||

Fireproof grade | Grade A | ||

Density | 120kg/m3 | ||

Steel Thickness | 0.3mm-0.6mm | ||

Effective Width | 950mm 960mm 1150mm | ||

Length | Arbitrary length , according to the transportation ,<12m< span="">

| ||

Zinc Galvanized | 120gr/ m2 Minimum | ||

Paint | 25/7 Micron Polyester Minimum | ||

Density | 120kg/m3 | ||

Temperature Range | -200°C~+ 150°C Specs | ||

Water Absorption Rate | Less than 0.118 | ||

color | Polyester Varnish With Standard Color Shade | ||

Rock Wool Thickness | 50mm | 75mm | 100mm |

Plate Weight KN/m2 | 0.178 | 0.263 | 0.301 |

Heat transfer coefficient W/M2K | 0.749 | 0.530 | 0.411 |

Kcal/m2.h. °C | 0.644 | 0.456 | 0.353 |

Certification | ISO9001:2000 | ||

COMMENT | Qualified. The item tested is in accordance with the national standard of P.R.OF China completel | ||

Applications for Rock Wool Sandwich Panels

Rockwool Sandwich Panels have been widely used in steel structure warehouse, factories, exhibition hall, container houses, cold storage, etc.

We can supply all kinds of Sandwich Panels such as: EPS Sandwich Panels. Rock wool Sandwich Panels, PU Sandwich Panels … and also can supply as your requests.

FAQ

A, Could be changed the size of the panel?

Yes, we design the size according to your requirement.

B, What is the color of the panel?

All the colors in "RAUL"

- Q: Polyurethane sandwich panels in the polyurethane is what material, what are the benefits of industrial building materials should choose polyurethane?

- Foam benzene board capacity of not less than 18kg, other indicators in line with national regulations

- Q: Are sandwich panels suitable for automotive showrooms?

- Yes, sandwich panels are suitable for automotive showrooms. These panels provide excellent insulation, durability, and aesthetic appeal, making them a practical choice for creating a modern and visually appealing showroom. Additionally, sandwich panels can be customized to meet specific design requirements and offer ease of installation, making them a suitable option for automotive showrooms.

- Q: What is the difference between the board and the core board? The The

- 024 (thermal conductivity of the lower insulation effect The better) Polyurethane sandwich panels used in the filling process of polyurethane, pre-made pre-insulation board directly installed on-site use If your plant area is relatively large, it is recommended that you only use the whole color plate, and then use the field of polyurethane spray foam process, this process than the infusion process is the advantage of spraying seamless, better insulation The cost is still lower than the infusion process

- Q: Sandwich panels and Malacca ecological board what is the difference

- Not count But it is best to mark the gun in the obvious place.

- Q: Are sandwich panels suitable for food kiosks?

- Yes, sandwich panels are suitable for food kiosks. Sandwich panels are commonly used in the construction of food kiosks due to their durability, insulation properties, and ease of installation. They provide a hygienic and easy-to-maintain surface, making them ideal for food-related businesses. Additionally, sandwich panels offer flexibility in design and can be customized to meet specific requirements, making them a popular choice for food kiosks.

- Q: Color steel sandwich panel price table color steel sandwich board how much money a square meter

- Height of 24m below the double scaffold can be flexible connection, but must be used to withstand the tension and pressure structure.

- Q: 800 * 800 tiles can not stick to the sandwich panel on the wall to do

- The inner panel can be installed with conventional technology, pay attention to the edge, the installation of corners, as well as their installation with the wallboard order, part of the first to install

- Q: Color steel sandwich panels and synthetic resin tile which is more market

- JGJ130-2011 "construction construction fastener steel scaffold safety technical specifications" in the provisions of the external scaffolding should be used rigid wall pieces.

- Q: Color steel tile and Caigang sandwich board What is the difference between the use of what is the difference

- Door scaffolding, fastener steel scaffolding, bowl button steel pipe scaffolding, socket-type steel scaffolding. It is best to pay for the work of the scaffolding to learn the preparation of scaffolding program

- Q: What is the difference between rock wool sandwich panels, EPS sandwich panels and polyurethane sandwich panels?

- With the construction specifications quickly calculated to you, you can call me, I am a professional to do this full of construction team

Send your message to us

Insulated Sandwich Panels with Rockwool for Prefab House

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords