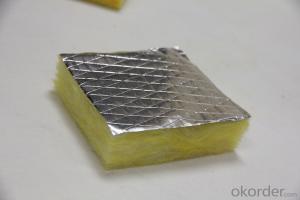

Aluminum Foil Facing Rock Wool Board for Wall Partition Insulation

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 700 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. INTRODUCTION

CMAX ROCK WOOL are widely used in public, commercial an residential building as well as industrial plants, for applications such as roofing, external wall, partion wall and floating floor to provide fire protection, thermal insulation, acoustic control and condensation control.

2. FEATURES

● Thermal Insulation

● Fire Safety

● Acoustic Control

● No Corrosion

● Environmental friendly

● Moisture Resistance

● Energy Conservation & Emissions Reduction

3. CMAX ROCK WOOL BLANKET & BOARD STANDARD SIZE

PRODUCT | BLANKET | BOARD |

Density(Kg/m3) | 60-100 | 40-200 |

Thickness(mm) | 30-150 | 30-100 |

Size:L*W(mm) | 1200*3000-6000 | 600*1200 |

Remark:

Other sizes are available unpon request. Facing materials can be applied unpon request.

4. PRODUCTION THECHNOLOGY

CMAX rock wool is made from natural rocks such as basalt and limestone. The rocks are melted in a cupolaat temperature of >1450℃, and the molten lava is fiberized by a spinner. The inorganic fibers are bondedtogether using a thermosetting resin to form the final product which is cut into suitable sizes for easyhandling and installation. Other products such as wired blanket, pipe cover or faced products are producedby secondary process

5.FAQ:

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 40 working days can be served.

4.Packing,Tranportation and Storage

Product is packed in polythene plastic shrink film or plastic bag. During transportation and storage, please keep product away from moisture and compressive deformation.

5.FAQ:

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Is it possible to use aluminum foil facing as a substitute for a pizza crust?

- <p>While it's not conventional, you can technically use aluminum foil facing as a makeshift pizza crust in a pinch. However, it won't provide the same texture or taste as a traditional crust. Aluminum foil is not designed for consumption and lacks the nutritional value of a real pizza crust. It's advisable to use a proper pizza dough or a store-bought crust for the best results. If you're in a bind, consider alternatives like using a tortilla or flatbread for a makeshift crust.</p>

- Q: What are the recommended cleaning products for aluminum foil facing after use?

- <p>For cleaning aluminum foil facing after use, it's best to use gentle, non-abrasive cleaning products. Mild dish soap and warm water are usually sufficient for most cleaning needs. Avoid using harsh chemicals or abrasive scrubbers, as they can damage the aluminum surface. If there are stubborn stains, a mixture of baking soda and water can be used as a gentle abrasive. Always rinse thoroughly and dry the surface to prevent any residue or potential damage.</p>

- Q: This question asks for clarification on the distinction between two types of aluminum products: aluminum foil facing and aluminum foil sheet.

- <p>Aluminum foil facing is a thin layer of aluminum laminated to a substrate, typically used in construction for insulation and moisture barrier purposes. It provides a reflective surface that can enhance energy efficiency by reflecting heat. On the other hand, aluminum foil sheet is a flat, flexible material made of pure aluminum or aluminum alloy, commonly used in cooking, food packaging, and crafts. It is not bonded to any other material and is available in various thicknesses and widths. The primary difference lies in their applications and composition; foil facing is part of a composite material for construction, while foil sheets are standalone materials for a variety of uses.</p>

- Q: Is it safe and practical to use aluminum foil facing as a protective layer for a cutting board?

- <p>Yes, you can use aluminum foil facing as a temporary cover for a cutting board. It provides a smooth surface that can protect the cutting board from scratches and stains. However, it's not recommended for long-term use or heavy-duty cutting as it may tear or dent easily. For regular use, a proper cutting board cover or a plastic cutting mat is more durable and safer.</p>

- Q: Is it safe to use aluminum foil facing to wrap food for cooking methods like roasting or grilling?

- <p>Yes, you can use aluminum foil facing to wrap food before roasting or grilling. Aluminum foil is a common and safe material used in cooking, especially for wrapping foods to retain moisture and flavor. It's important to ensure the foil is food-grade and not damaged, as this can affect the food's safety and taste. When using foil, make sure it's sealed properly to prevent juices from leaking and to keep the food moist. Avoid direct contact with the heat source as much as possible to prevent the foil from burning and potentially releasing any harmful substances into the food.</p>

- Q: This question asks about potential health hazards linked to consuming food that has been wrapped in aluminum foil.

- <p>There are minimal health risks associated with eating food wrapped in aluminum foil. Aluminum foil is generally safe for cooking and food storage. However, it's important to avoid wrapping acidic or high-sodium foods in aluminum foil, as these can cause the foil to corrode and potentially release small amounts of aluminum. Long-term consumption of aluminum in large quantities has been linked to rare health issues, such as Alzheimer's disease, though this link is not definitively proven. To be safe, use aluminum foil sparingly and avoid wrapping foods that are highly acidic or salty.</p>

- Q: What are the chemical characteristics of the side of aluminum foil that faces outwards?

- <p>The chemical properties of the aluminum foil facing outward are primarily determined by its elemental composition, which is aluminum (Al). Aluminum is a lightweight, soft, and malleable metal with a silvery-white appearance. It is highly reactive and readily forms a thin, protective oxide layer (aluminum oxide) when exposed to air, which prevents further oxidation. This oxide layer is what gives aluminum foil its resistance to corrosion and its shiny appearance. Aluminum is also a good conductor of heat and electricity. The facing side of the aluminum foil may have slight differences in properties due to the manufacturing process, but fundamentally, it remains chemically similar to the rest of the aluminum foil.</p>

- Q: Is there a concern that aluminum from aluminum foil can seep into food during cooking or storage?

- <p>There is minimal risk of aluminum leaching from aluminum foil into food. Aluminum foil is generally safe for cooking and food storage when used properly. The risk increases with acidic or alkaline foods and high temperatures, but under normal cooking conditions, the amount of aluminum that could leach is negligible. However, it's best to avoid wrapping food in aluminum foil for long periods or at very high temperatures to minimize any potential exposure.</p>

- Q: This question asks about the various types of aluminum foil facing used in construction and insulation materials.

- <p>Aluminum foil facing is used in various applications, including insulation and construction materials. The different types include: 1) Plain Foil Facing, which is a smooth, uncoated aluminum foil; 2) Coated Foil Facing, which has a protective coating applied to one or both sides; 3) Laminated Foil Facing, where aluminum foil is bonded to other materials like polyester or polyethylene; 4) Embossed Foil Facing, featuring a pattern or texture on the surface for added strength or aesthetic purposes; and 5) Reinforced Foil Facing, which incorporates additional materials to enhance durability and tear resistance.</p>

- Q: This question asks for the optimal methods of storing food in containers not made of traditional food-safe materials.

- <p>The best ways to store food in containers made from alternative materials involve ensuring the containers are food-safe and do not impart any harmful substances to the food. For glass containers, ensure they are free of lead and are properly sealed to maintain freshness. For stainless steel containers, avoid those with non-food-grade coatings and ensure they are well-sealed to prevent spoilage. For silicone or plastic containers, look for BPA-free options and avoid high temperatures that could cause the material to leach chemicals. Always check for any odors or tastes that the container might impart to the food, and never store acidic foods in non-acid-resistant containers as this can lead to chemical reactions and contamination.</p>

Send your message to us

Aluminum Foil Facing Rock Wool Board for Wall Partition Insulation

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 700 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords