Aluminum Foil Facing Mylar Bubble Heat Seal Composite Film

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 32 inch

- Supply Capability:

- 123 inch/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Aluminum Foil Facing Description:

Aluminium foil laminated with PET film

PET laminated aluminum foil is an improved surfacing material for SBS/APP modified bitumen waterproofing membrane.

PET laminated aluminum foil is an improved surfacing material for SBS/APP modified bitumen waterproofing membrane. It has all the aluminum foil functions. Since it is the lamination of PET/PE film and aluminum foil, it is more flexible and with higher strength.

Technical Data

PROPERTIES | TYPICAL DATA |

COMBINED THICKNESS | 35--40 MICRON |

PET FILM:12MICRON ALUMINUM FOIL:10MICRON PET FILM:12 MICRON | |

UNITE WEIGHT | 60-70 G/M2 |

WIDTH | 1020 MM |

SURFACE FINISH | TOP: PET FILM MIDDEL: ALUMINUM FOIL BOTTOM: PET FILM |

TENSILE STRENGTH | LONGITUDINAL> 40 N/15MM TRANSVERSAL> 50 N/15MM |

ELONGATION AT BREAK | LONGITUDINAL>10 TRANSVERSAL>15 |

I.D. | 75-80MM |

O.D.OF ROLL | 450-550MM |

SD VALUE | 7000M(APPROX) |

WATER VAPOUR PERMEABILITY | <0.02 G/M2 D |

COMPOUND CHARACTERISTICS | THE COMPOUND DOES NOT CHANGE ITS CHARACERISTICS WHEN USED AT 180 °C IN A SHORT BITUMEN CYCLE |

2.Main Features of the Aluminum foil facing:

• Light weight

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• High reflective insulation

• Heat resistant, water proof, stable at high temperature;

• environmentally friendly,no smell and not-toxic;

• Smooth and clear surface;

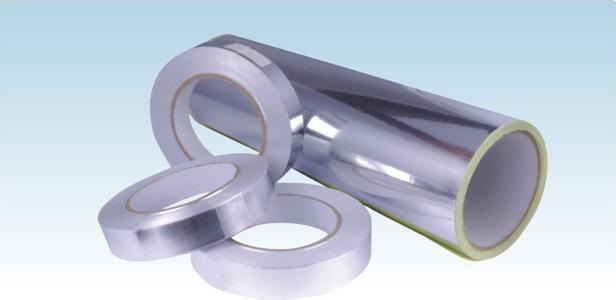

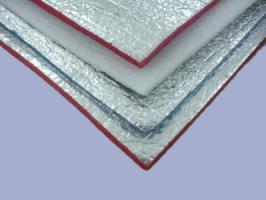

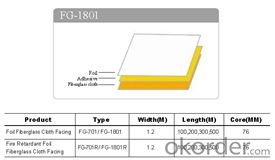

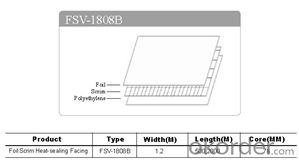

3.Aluminum Foil Facing Images

4.Aluminum Foil Facing Specification

TYPICAL PHYSICAL PROPERTIES:

PROPERTIES | UNIT | VALUE | TEST METHOD | |||||

Basic weight | gsm | 120 | ASTM D646 | |||||

Tensile strength: M. D. X. D. | N/25mm | 180 90 | ASTM C1136 | |||||

Burst strength | N | 50 | ASTM D774 | |||||

Reflectivity of foil surface | % | 95 | ---------- | |||||

Temp. Resistance | -29°C +66°C | No change keep soft | ASTM C1263 | |||||

Water vapor permeance | ng/N.s | 5.75 | ASTM E-96 | |||||

Water Soak Test | 24hrs | No delamination | ---------- | |||||

Width: 1.0 m, 1.2m, 1.25m, 1.3m

Length: 60m,100m,120m, 200m

Core I.D.: 3"(76mm ±1)

Based on order, special sizes are also available.

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

1. How about your company?

A world class manufacturer & supplier of aluminum foil facing and is one of the large-scale professional investment aluminum foil facing bases in China. Annually more than 1000 containers of aluminum foil facing are exported to markets in Europe, America and Japan.

1. What is the storage condition?

1,The products should be stored at room temperature and kept from wet and heat source.

2, It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

3, The user should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: Is it possible to use aluminum foil facing as a material for baking goods?

- <p>Yes, aluminum foil facing can be used to make baked goods, but it's important to use it correctly. Aluminum foil is a common material used in baking for lining baking sheets and pans to prevent sticking and to facilitate easy removal of baked goods. It's crucial to ensure that the foil is food-grade and safe for use with food. When using aluminum foil, make sure it covers the bottom and sides of the pan to prevent direct contact between the food and the pan, which can lead to uneven cooking or burning. Additionally, avoid using aluminum foil in broilers or at very high temperatures as it may melt or create a fire hazard.</p>

- Q: Is it hazardous to cook acidic or salty foods with aluminum foil?

- <p>Using aluminum foil with highly acidic or salty foods is generally safe, but it's important to use the correct type of foil. Heavy-duty aluminum foil is designed for cooking and is safe for use with acidic and salty foods. However, avoid using aluminum foil with reactive metals, as it can cause a chemical reaction. Always follow cooking instructions and be cautious with prolonged cooking times or high temperatures, as these can potentially cause the foil to break down and release small amounts of aluminum into the food. For best results, opt for non-reactive cookware or use parchment paper or silicone baking mats as alternatives.</p>

- Q: Is aluminum foil a healthier alternative to plastic wrap?

- <p>Aluminum foil may have some health benefits over plastic wrap due to its non-porous nature, which prevents the absorption of flavors and odors. It's also heat resistant, making it suitable for cooking and reheating food. However, aluminum foil doesn't cling to surfaces as well as plastic wrap, making it less convenient for sealing food. Additionally, there are concerns about aluminum exposure, though the risk is considered low when used in cooking. It's important to note that the health benefits of using aluminum foil over plastic wrap are not definitively established, and both have their pros and cons.</p>

- Q: What are the potential health advantages of using food packaging that does not contain aluminum?

- <p>Yes, there are health benefits associated with using aluminum-free food packaging. Aluminum has been linked to potential health risks, including Alzheimer's disease and neurological disorders. By avoiding aluminum in food packaging, there's a reduced risk of exposure to this metal, which can leach into food, especially when heated. This can help minimize the intake of aluminum, potentially lowering the risk of related health issues. Aluminum-free packaging also reduces the environmental impact and is often more sustainable, contributing to overall health by promoting a cleaner environment.</p>

- Q: What are the eco-friendly options available to replace plastic containers?

- <p>Yes, there are several alternatives to plastic containers that are more environmentally friendly. Glass containers are a popular choice due to their durability and ability to be reused multiple times. Stainless steel containers are also a great option as they are long-lasting and do not leach chemicals. Biodegradable materials like bamboo, silicone, and certain types of plant-based plastics are other alternatives. Additionally, using cloth bags or reusable food wraps can help reduce the need for single-use plastic containers.</p>

- Q: What are the most effective ways to clean surfaces that have aluminum foil applied to them?

- <p>The best cleaning methods for aluminum foil facing involve gentle cleaning to avoid damaging the foil. Use a soft cloth or sponge with warm water and mild dish soap to wipe the surface. Avoid abrasive cleaners or scrubbing, as this can scratch or tear the foil. For stubborn stains, a mixture of baking soda and water can be applied as a paste and gently rubbed with a soft cloth. Always rinse thoroughly and dry the surface to prevent water spots and maintain the integrity of the aluminum foil.</p>

- Q: Is it possible to use aluminum foil as a cooking utensil for stir-frying or sauteing food?

- <p>While aluminum foil can be used in some cooking applications, it is not recommended for stir-frying or sauteing due to its low melting point and potential for tearing. Aluminum foil can melt at high temperatures, which are often used in stir-frying and sauteing, leading to a fire hazard or uneven cooking. Additionally, the foil may tear or puncture easily, releasing aluminum particles into the food, which is not safe. Instead, use proper cookware like non-stick pans or stainless steel for these cooking methods.</p>

- Q: This question asks for the method to wrap a hot pan using aluminum foil, with specific instructions on how the foil should face.

- <p>To wrap a hot pan with aluminum foil, first ensure the pan is stable and on a heat-resistant surface. Take a large piece of aluminum foil, about twice the size of the pan. Hold one corner of the foil and drape it over the pan, allowing the shiny side to face the pan. Gently press the foil against the pan, working your way around the edges to cover the entire surface. Ensure the foil is snug but not too tight to avoid tearing. The shiny side facing the pan will help reflect heat and protect the pan's surface. Be cautious while handling the hot pan and aluminum foil to avoid burns.</p>

- Q: Is it safe to use old aluminum foil for food packaging, considering potential health risks and material degradation?

- <p>Using old aluminum foil for food packaging is not recommended. Over time, aluminum foil can become discolored, thin, or develop pinholes, which can compromise its integrity. These changes can lead to food contamination and the foil's ability to protect food from bacteria or other contaminants. Additionally, old aluminum foil may contain residues from previous uses that could mix with new food items, potentially causing off-flavors or health concerns. It's best to use fresh, clean aluminum foil for food packaging to ensure safety and hygiene.</p>

- Q: What are some effective techniques or suggestions for utilizing aluminum foil in various applications?

- <p>Using aluminum foil effectively involves a few tricks: 1) For cooking, use a double layer to prevent food from sticking and to distribute heat evenly. 2) When grilling, crumple the foil to create a heat-reflective dome for indirect cooking. 3) Line baking sheets with foil to simplify cleanup. 4) Use foil to create makeshift containers for baking, such as foil packets for vegetables or fish. 5) For storage, wrap food tightly to preserve freshness. 6) When roasting meats, tent with foil to lock in moisture. 7) Use foil to create a barrier between food and the grill grates to prevent flare-ups. Remember, avoid using foil with acidic foods as it can react and release aluminum into the food.</p>

Send your message to us

Aluminum Foil Facing Mylar Bubble Heat Seal Composite Film

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 32 inch

- Supply Capability:

- 123 inch/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords