Ring-Lock Scaffolding Table Formwork

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

1. Brief introduction

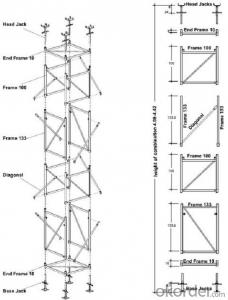

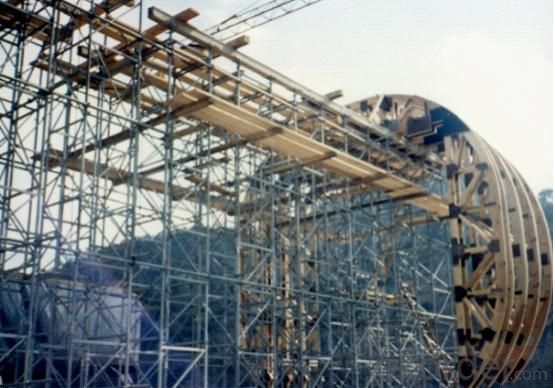

FA-TNOR system is widely used for pouring slab concrete, especially for the building which has higher story height that only using props can’t meet requirements. The system guarantees quick assembly, simple structure and easily operation, it is good choice for slab construction.

2. About the infill areas

Like RA-INST system, infill materials are necessary for small space or same special area. They are usually composed of timber beam, head-jack, scaffold support, and plywood as the below picture shown.

3. Competitive advantage

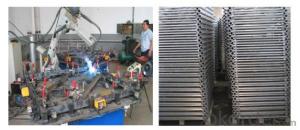

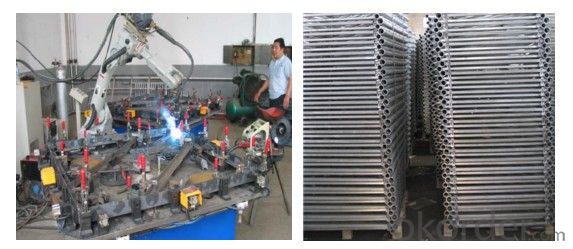

① Fast construction

The table formwork is pre-assembled; all the structural elements are connected by specific fastenings, so it is easily to move and turnover.

②Easy operation

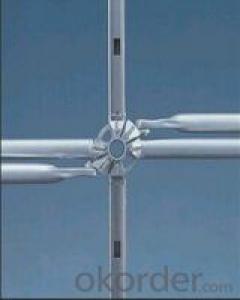

The formwork is composed of plywood, timber beam, channel beam, connectors and ring-lock scaffolding support system. It’s easy to assemble for labors with simple structure. Special skill train is no needed.

③Height of scaffolding is adjustable

Table formwork is supported with adjustable scaffoldings; the scaffoldings can be pivoted in two directions for meeting the demand of different height with adjustable head jack and adjustable foot jack.

④Mature system with specific tools for removing.

We afford trolley for FA-TNOR system, trolley is especially for shifting table formwork from the slab, it guarantees easy operation and safe removing.

4. Applications

- Q: What are the maintenance and maintenance of hydraulic climbing formwork

- Regular inspection of the climbing device should check the connections. In particular, the following parts of the site to focus on inspection and reinforcement: according to the design requirements of the bolt with spring washers

- Q: Climbing frame is divided into several kinds, what is its running mode? What is the rental cost? Please explain in detail! Thank you very much

- Install the lifting seat and a guide seat is connected with the high wall, main frame vertical rod, the frame set up to the designed height, laying the top scaffold, block feet - laying bottom safety nets and scaffolding, making turning plate - the upper part of the frame body structure and effective tie (tie spacing is not greater than 6m) - display efflux dense mesh safety net to the top of the shelf, the anti dropping boom is inserted into the base anti dropping device, the installation of steel rope - placed distribution cables, installation control cabinet, electric hoist, electric wiring and debugging system, pre inspection, electric hoist, demolition of frame body and the upper structure of pulling and synchronization a layer - installation completed, enter the upgrade cycle

- Q: The difference between the scaffold and the scaffold

- The difference between climbing frame and scaffolding is commonly used scaffolding from below has been set up, which is followed by building up climbing frame, the figure is upstairs, they have in common is that we are like scaffolding

- Q: Advantages and disadvantages of climbing frame and floor type scaffold

- 3, compared with the economy, the processing is simple, and the investment cost is low; if the geometric dimensions of the scaffold are carefully designed, and the utilization rate of the steel tube is improved, the material consumption can also obtain better economic effect. Fastener steel pipe frame equivalent to 15 square meters per square meter of construction steel.

- Q: The whole concrete wall climbing frame or good use of steel scaffolding

- Climbing frame, also known as the lifting frame, according to its source of power can be divided into hydraulic, electric, manual pull and other major categories. It is a new type of scaffolding system developed in recent years, which is mainly used in high-rise shear wall construction

- Q: What is an integrated climbing frame? What are the works? What are the advantages

- The climbing frame, which is also called the lifting frame, can be divided into several types, such as hydraulic, electric, manual and so on. It is a new type of scaffolding system developed in recent years, which is mainly used in high-rise shear wall construction.

Send your message to us

Ring-Lock Scaffolding Table Formwork

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords