Trustworthy Auto-Climbing Bracket

- Loading Port:

- XINGANG

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 Sets set

- Supply Capability:

- 10000 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Introduction of the Trustworthy Auto-Climbing Bracket

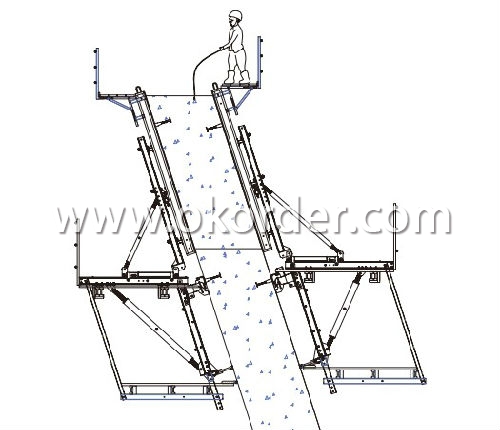

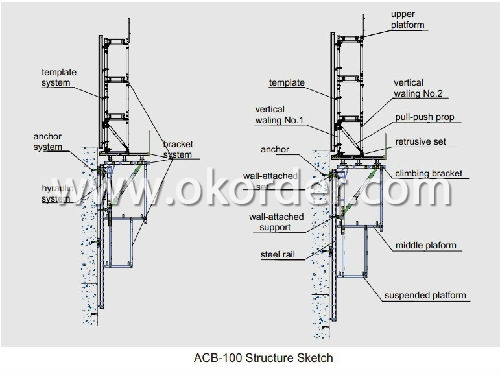

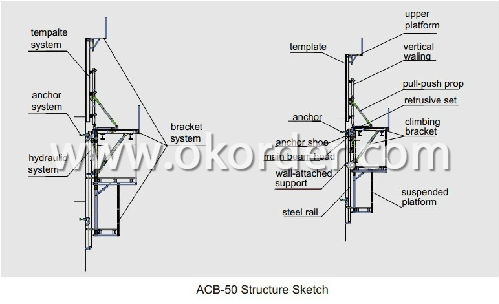

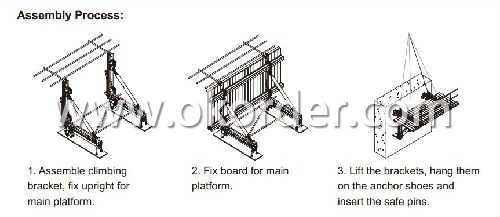

The power of the auto-climbing formwork is the hydraulic system,which includes the oil cylinder and two commutators.The commutators can control the climbing of climbing rail and the bracket.The steel rail and the bracket can inter-climbing,so the whole system will climb up steadily.Cranes are not needed during the construction.It's easy to operate,highly efficient and safe.it's the best choie for the construction of high buildings and bridges.

There are mainly two types of standard auto-climbing brackets,ACB-50 and ACB-100, the figure means the push power of cylinder with unit of KN.

2.Characteristics of Auto-Climbing Bracket

Perfect load bearing anchor system.

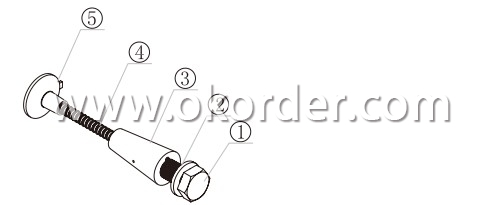

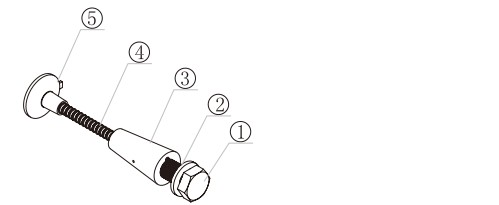

Anchor system is the most important supporting part.The system is made of five parts shown below.Thereinto,tensile bolt,V-climbing cone and washer can be taken out for reusing after the concrete pouring finished.There are two kinds of anchor systems,A&B.A is matched with single anchor shoe and B is matched with double anchor shoe.

Anchor system assembly A(Matched with single anchor shoe)

1,Tensile Bolt M42 1.60 09000194

2, Washer 78/52 0.21 01091610

3, V-climbing Cone M42/D20 2.78 09001204

4, High-strength Rod D20/L=300 0.81 09000241

5,Anchor Plate D20 0.65 09000102

Anchor assembly B(Matched with double anchor shoe)

1,Tensile Bolt M36 1.05 09000191

2,Washer 65/46 0.14 01091611

3,V-climbing Cone M36/D20 1.77 09001203

4,High-strength Rod D20/L=300 0.81 09000241

5,Anchor Plate D20 0.65 09000102

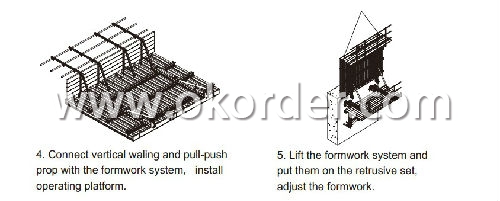

Crane-independent

Crane-independent forming,striking and climbing speeds up the work procedures on the construction site and also makes them independent of each other.This means the planned sequences can be maintained along with guaranteeing high productivity levels.The crane can therefore be used for other tasks.

Hydraulic system is mainly made of two commutators,oil cylinder and power disribution system.The commutator can control the climbing of climbing rail and bracket

High bearing capacity and safe

The stable working platforms are able to carry large loads,e.g.The storage of reinforcing steel for the next climbing section.Generously-sized working platforms, the well thought-out design for handing very high wind loads and the patented control function of the climbing mechanism are some of the special details contained within the comprehensive safety concept.

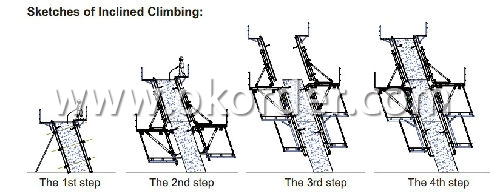

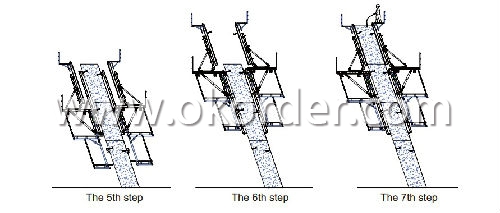

Platforms adjusted to suit the angle of inclination

The horizontal working areas thus created provide safe and comfortable conditions for reinforcement work,shuttering and striking,concreting and finishing.

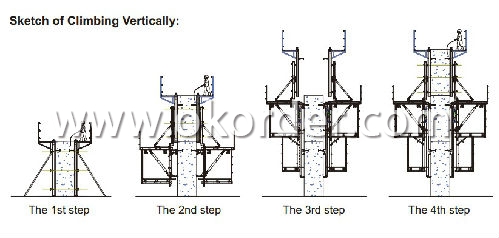

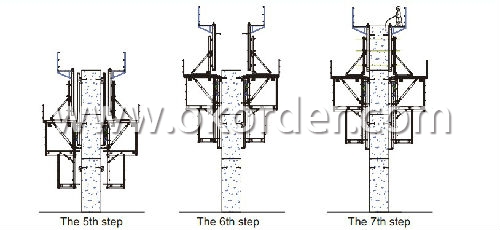

The ACB formwork system can climb not only vertically but also slantways,the largest angle is 18 degrees.

The system can climb up wholly or separately.The climbing process is steady,synchronous and safe.

The bracket will not fall to the groud until the construction is finished,the field will be saved an the impacting breakage will be reduced (especially the panel).

The system will furnish omnidirectional platform,the construction organizations don't need to set up additional operation platform.

The error of structure construction is small and easy to correct.

The climbing speed is fast,the construction course will be quickened.

The formwork can climb itself and cleaning work can be done in the same situs,the used times of tower crane will be greatly reduced.

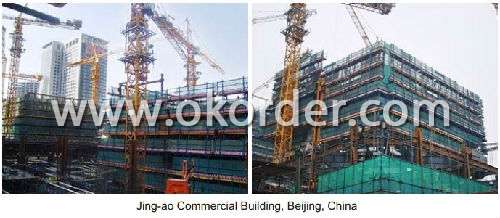

3.Project Application of Auto-Climbing Bracket

- Q: What are the maintenance and maintenance of hydraulic climbing formwork

- Whether or not the double screw nut is used on the important bolt connection, the degree of the fastening, whether the steel bar is pressed according to the rules, and the steel wires are bundled together

- Q: Climbing frame is divided into several kinds, what is its running mode? What is the rental cost? Please explain in detail! Thank you very much

- Climbing frame, also known as the lifting frame, according to its source of power can be divided into hydraulic, electric, manual pull and other major categories. It is a new type of scaffolding system developed in recent years, which is mainly used in high-rise shear wall construction. It can climb up or down the building. This system makes the change scaffolding Technology: one is without turning over the shelf; two is exempt from the disassembly process of scaffold (an assembly has been used after the completion of construction, and not affected) building height restrictions, greatly saves manpower and material. And in terms of security is also a big change for the traditional scaffolding. Highly developed in high-rise buildings.

- Q: The difference between the scaffold and the scaffold

- The difference between climbing frame and scaffolding is commonly used scaffolding from below has been set up, which is followed by building up climbing frame, the figure is upstairs, they have in common is that we are like scaffolding

- Q: Advantages and disadvantages of climbing frame and floor type scaffold

- Floor scaffold:Advantage:1) large bearing capacity. When the scaffolding geometry and structure comply with the relevant requirements, under normal circumstances, the bearing capacity of 15kN ~ 35kN of the single column scaffold (1.5tf ~ 3.5tf, design value).

- Q: The whole concrete wall climbing frame or good use of steel scaffolding

- Floor scaffold:Advantage:1) large bearing capacity. When the scaffolding geometry and structure comply with the relevant requirements, under normal circumstances, the bearing capacity of 15kN ~ 35kN of the single column scaffold (1.5tf ~ 3.5tf, design value).Clamp and Tube Scaffold2) easy to install and disassemble, set up flexible. Because the length of the steel tube is easy to adjust and the fastener is convenient to connect, the utility model can be used for various buildings and structures with various planes and elevations.3, compared with the economy, the processing is simple, and the investment cost is low; if the geometric dimensions of the scaffold are carefully designed, and the utilization rate of the steel tube is improved, the material consumption can also obtain better economic effect. Fastener steel pipe frame equivalent to 15 square meters per square meter of construction steel.

- Q: What is an integrated climbing frame? What are the works? What are the advantages

- . It can climb up or down the building. This system makes the change scaffolding Technology: one is without turning over the shelf; two is exempt from the disassembly process of scaffold (an assembly has been used after the completion of construction, and not affected) building height restrictions, greatly saves manpower and material

1. Manufacturer Overview

| Location | Shanghai,China |

| Year Established | 1949 |

| Annual Output Value | Below US$1 Million |

| Main Markets | North America South America Eastern Europe Southeast Asia Africa Oceania Mid East Eastern Asia Western Europe Central America Northern Europe Southern Europe South Asia Domestic Market |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | SHANGHAI |

| Export Percentage | 91% - 100% |

| No.of Employees in Trade Department | 200 |

| Language Spoken: | English,Chinese |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Trustworthy Auto-Climbing Bracket

- Loading Port:

- XINGANG

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 Sets set

- Supply Capability:

- 10000 Sets per Month set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords