Ring-Lock Scaffolding Table Formwork, Slab Formwork System

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ring-Lock Scaffolding Table Formwork with High Load Bearing Capacity

Description:

1. Brief introduction

FA-TNOR system is widely used for pouring slab concrete, especially for the building which has higher story height that only using props can’t meet requirements. The system guarantees quick assembly, simple structure and easily operation, it is good choice for slab construction.

2. About the infill areas

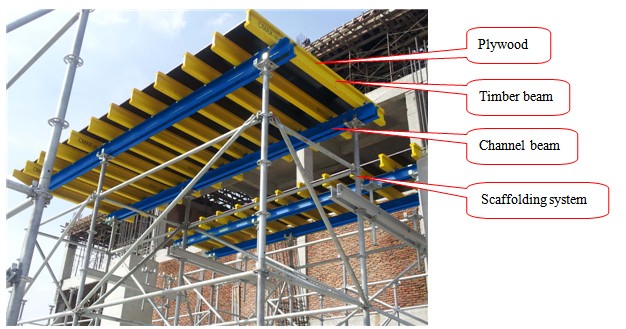

Like RA-INST system, infill materials are necessary for small space or same special area. They are usually composed of timber beam, head-jack, scaffold support, and plywood as the below picture shown.

3. Competitive advantage

① Fast construction

The table formwork is pre-assembled; all the structural elements are connected by specific fastenings, so it is easily to move and turnover.

②Easy operation

The formwork is composed of plywood, timber beam, channel beam, connectors and ring-lock scaffolding support system. It’s easy to assemble for labors with simple structure. Special skill train is no needed.

③Height of scaffolding is adjustable

Table formwork is supported with adjustable scaffoldings; the scaffoldings can be pivoted in two directions for meeting the demand of different height with adjustable head jack and adjustable foot jack.

④Mature system with specific tools for removing.

We afford trolley for FA-TNOR system, trolley is especially for shifting table formwork from the slab, it guarantees easy operation and safe removing.

4. Applications

- Q: Plastic construction template has no one used? How about the effect of using. How much can the main savings? Can really use 50 times?

- Solid can use foam technology to save costs, there is a hollow drawback in the use of the process, in the corner when the nail easily broken.

- Q: Who used it, how not universal.

- Strong plastic PP plastic template is a joint development of the company's patented product, is the national high-tech industrialization in 2000 to promote the project. The product is based on polypropylene, adding GF fiber, anti-aging additives made of a kind of engineering plastics. Is a plastic generation of steel (bamboo, wood) a new generation of building templates.

- Q: I heard that there are building aluminum template and plastic template it? Which is better?

- Aluminum alloy template is the best architectural template, the advantages of a high number of turnaround, the theory is 300 times, but the actual use of 60 will have a small part of the deformation, a comprehensive calculation of 150 no problem, the second is quick, every worker day Can be assembled 20 square meters or more, three is light weight, manual transmission is very convenient, do not rely on tower crane, four is the quality assurance, the basic can meet the specifications, five is conducive to civilized construction, will not produce garbage and noise, No wood. Disadvantages of a high cost, and second, only in the standard layer to use to play advantage

- Q: Europe and the United States national construction template is made of plastic or wood

- Part of the place with stones, as the case may be, but certainly yes, Europe and the United States have anti-seismic buildings

- Q: Who used plastic building templates? How is the effect? What are the advantages and disadvantages?

- The main advantages are:1, the surface smooth and smooth, high strength, the provincial workers, the expected material, can meet the requirements of clear water concrete template, after stripping without cleaning the surface of the template, thus saving a lot of labor, template flatness can be controlled within 0.3mm, thickness uniformity, Can be controlled within ± 0.3mm, wood than the wood to save 2/3 of the nails.2, good water resistance, toughness, long-term immersion is not layered, water swelling rate of less than 0.06%, in -30 ℃ _ +60 ℃ range of normal use, the use of 6 years of aging of 15%, normal use of 8 Years or more.3, plasticity, according to the design and component size requirements, processing and production of different shapes and different specifications of the template, a curvature of the template for the production of a more simple template can be drilling nails, saws, planing and other wood mold with the same machinability , On-site stitching simple and convenient.4, recyclable use, plastic template to a certain extent can be fully recycled, regardless of the size of the old and new, after processing, can be added to produce a new template

- Q: Plastic mold dynamic template, the size of the template

- A lot of it? What are you talking about? Plastic mold points a lot of tonnage, there are 80T, 120T, 240T, 1000T, 1250T

- Q: What is the economic benefits of building wood formwork compared to plastic molds?

- Both are their own strength, stiffness is not high, the turnover rate of the template material is low, but the cost is relatively low, due to different uses, can not be compared: wood sheet low cost, can be processed, the turnover rate is low, can not help blisters, if Small keel spacing is large, and the concrete side of the larger pressure, its own stiffness is low, there will be bending deformation or even up the mold, generally in the base floor or slope roof and other concrete appearance quality requirements are not high or one-time no longer a lot of turnover Parts of the use of plastic templates are generally stereotypes, such as ribbed floor in the plastic mold shell, is a specific structure with the template can be leased.

- Q: Plastic building template made of what material

- Plastic template (that also can be said that the composite template)

- Q: The price of raw materials can say better, is the PVC material.

- Templates in accordance with the different prices of materials are also very different. The general plywood is 50-65 / sheet.

- Q: Shear wall plastic template for the wall height and thick ratio requirements is how much?

- Should not be less than 160mm, and should not be less than the floor of the high 1/20; bottom reinforced parts of the wall thickness of not less than 200mm, and should not be less than the floor of the high 16/1. Hope to be helpful to you.

Send your message to us

Ring-Lock Scaffolding Table Formwork, Slab Formwork System

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 500 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords