reusable wall panels for concrete construction

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Plastic Formwork

reusable wall panels for concrete construction

Saving your time, money and energy !!!

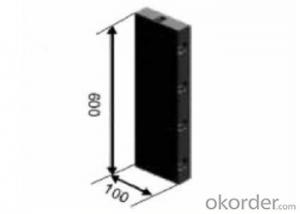

What is Details of our products reusable wall panels ?

Features:

1. Long lifespan& Cost effective -- Plastic formwork can be reused over 100 times,

where Plywood can only be reused 3 to 5 times. Therefore the Plastic Formwork

is more cost effective.

2. Waterproof -- As the nature of plastic material. It's imputrescible and rustless,

especially suitable for underground and watery circumstance.

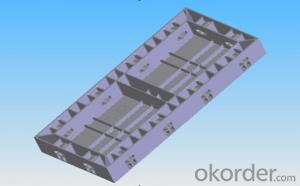

3. Interlocking Design -- No release agent needed, good effect of demolding.

4. Easy deassembly -- The template will be separated easily from concrete

5. Simple Installation -- Light weight and safe to handle, easy cleaning and very robust.

6. High Quality -- Abrasion resistance, excellent mechanical property, best impermeability.

7. Recycable -- Waste scrap molding board could be recycled.

What is Advantages of our company ?

Our anvantages

| High quality |

Reasonable price | |

| Strict delivery time | |

| Good after-sales service | |

Profession maker for 21 years | |

Gold supplier 9th year | |

Strict quality control | |

| professional injection mould | |

| 3D design |

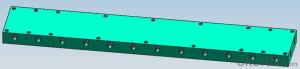

Product Photos/ reusable wall panels

FAQ:

1.Q:Are you a factory or trading company?

A: We are a factory of plastic formwork.

2.Q:Where is your factory located? How can I visit there?

A: Our factory is located in Taizhou City, China.You can fly to Ningbo airport directly.All our clients, from home or abroad, are warmly welcome to visit us!

3.Q:How can I get some samples?

A: We are honored to offer you samples.

4.Q:How does your factory do regarding quality control?

A:"Quality is priority. we always attach great importance to quality controlling from the very beginning to the very end. Our factory has gained ISOTS16949 authentication.

How to Contact Us?

If you are interested in our plastic formwork , please feel free to contact with us by email. We will quote you the best price, if you have drawings, we can help you caculate the quantity of plastic formwork .

Any building drawings is OK, just send us your drawing, we can make the plastic formwork quantity for you.

And we warmly welcome friends from all over the world to visit our factories for business.

- Q: Plastic deformation of the template how to solve or why the deformation Thank you I want the reason

- The lower the density of the foam board is easier to deform.Crust foam can be changed to coextrusion foam. General cross-linking or blending halogenation and other methods to improve Vicat. Reduce traction override

- Q: Plastic construction template has no one used? How about the effect of using. How much can the main savings? Can really use 50 times?

- By our site identification: hollow plastic building templates to protect the case of the use of 50 times is not a problem, even more than 50 times. Not capped Plastic non-stick cement. You know.

- Q: Why the floor is not plastic building materials square wood and template

- Is the plastic strong? The environment on the site you know, throw off how to do, have to find strong and durable.

- Q: Does the building plastic template use it? How's the effect? Can I use 30 to 50 times? Can the fire protection requirements of the steel plate on the cast-in-place plate be achieved?

- Plastic template this line, and now China is not perfect, may reach less than 30-50 this requirement, but better than the wood template, fire requirements should be able to achieve.

- Q: Europe and the United States national construction template is made of plastic or wood

- Although the problem is not understand the landlord can not help.

- Q: Types of building templates? What is the water template?

- With the development of the economy, the emergence of new materials in the building materials industry, the increasing number of types of building classification, there are four types of building templates

- Q: Is there a kitchen toilet to seal the water pipe plastic template? Where to sell?

- The general building materials market have to sell, I hope my answer can help you ~

- Q: The price of raw materials can say better, is the PVC material.

- Usually in square meters. But whether by square meters or by weight count, but the process is different, but the results will be the same unit price. Off to know how much the cost of this product, how much profit. The cost of each product produced by the factory are not necessarily, of course, the profit is not the same. Cost is the material, management, plant rent, utilities, machine depreciation and other costs together, and now PVC materials have different grades, the specific price can be found on the Internet to see.

- Q: Will the plastic building template on the builders really do not use the price is how much price

- Easy to use, heat insulation. A lot of building materials market there ah, to see what you want the model, the price range,

- Q: Shear wall plastic template for the wall height and thick ratio requirements is how much?

- Plastic building template to be extended when the expansion joints: As the plastic building template than the steel mold, wood mold thermal expansion coefficient larger, morning and evening laying plastic template must be reserved for about 2 mm expansion joints (according to the size of the day the temperature difference ), No need to reserve the expansion of the slit at noon. The length of the nail is generally 1.5 inches to 2 inches is appropriate, not too long or too short.

Send your message to us

reusable wall panels for concrete construction

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords