Plastic Concrete Formwork Accessories for Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 80000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

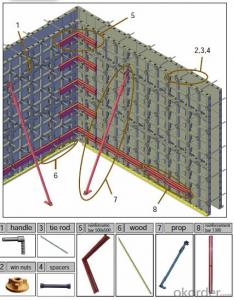

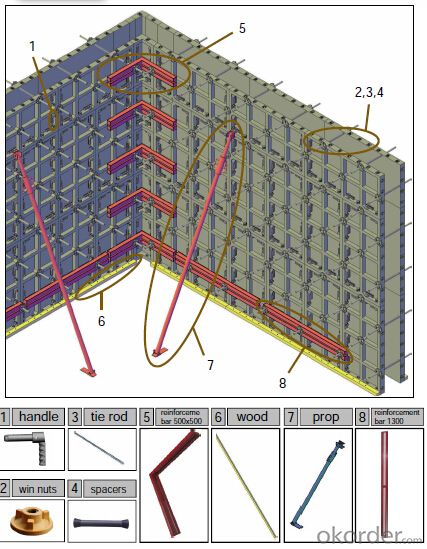

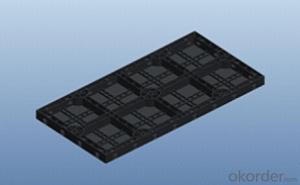

1. Structure of Plastic concrete formwork-Round panel

Plastic concrete formwork is more and more popular in the market. It consist of wall panel, corner panel, column panel, corner block and round panels. It is a very adjustable and flexible modular formwork and works quite efficiently.

Plastic formwork do not many accessories and it only need handles,plugs, washers and reinforcements. As for its supporting system, it may need prop, fork, tripod, and H20 beam.

2. Main Features of Plastic concrete formwork Accessories

-easy set up

-modularity work

-High strength

-enviroment friendly

-consequent

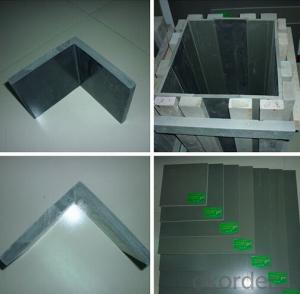

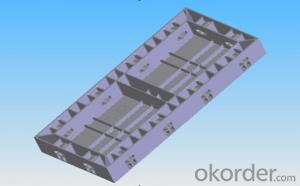

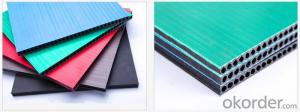

3. Plastic concrete formwork accessories images

4. Plastic concrete formwork accessories Specifications

The material are mostly steel, pp, nylon , wood.

5. FAQ of Plastic concrete formwork accessories

1) What can we do for you?

.We can ensure the quality of Plastic concrete formwork accessories panel and avoid extra expenses for customers.

.We can provide you the professional technical team.

.We can provide professional building proposal for your projects.

2) What promises can be done by us?

. please feel free to write us for any QUOTE.

. If need any technical and building assistance, we could provide on-site professional staff for instruction.

. Please DO check goods when courier knocks your door and contact us asap if any issues.

- Q: Plastic deformation of the template how to solve or why the deformation Thank you I want the reason

- The lower the density of the foam board is easier to deform.Crust foam can be changed to coextrusion foam. General cross-linking or blending halogenation and other methods to improve Vicat. Reduce traction override

- Q: Plastic construction template has no one used? How about the effect of using. How much can the main savings? Can really use 50 times?

- It seems to have been the introduction of hollow plastic building template production line (foreign technology), the site last year to see someone used this plastic building template, our site is now using this plastic building template material is polypropylene PP, this template Cheap, suitable for ordinary wall. There is also a material that is made of polycarbonate PC This material is suitable for viaducts, water conservancy works, pouring walls without whitewashing. The wall is very light. It is expensive point.

- Q: I am a novice, do this product development, and now design a set of products, and now take the product to open the mold, it is not clear what kind of material template selection! Please advise experts who look

- This is not know your product materials and performance requirements, but the mold, then we generally use 45 steel, if the product is not corrosive strong, then what can be used to compare 50 steel.

- Q: I heard that there are building aluminum template and plastic template it? Which is better?

- Aluminum alloy template is the best architectural template, the advantages of a high number of turnaround, the theory is 300 times, but the actual use of 60 will have a small part of the deformation, a comprehensive calculation of 150 no problem, the second is quick, every worker day Can be assembled 20 square meters or more, three is light weight, manual transmission is very convenient, do not rely on tower crane, four is the quality assurance, the basic can meet the specifications, five is conducive to civilized construction, will not produce garbage and noise, No wood. Disadvantages of a high cost, and second, only in the standard layer to use to play advantage

- Q: We have to start the construction site immediately, and have not used this plastic building template; I would like to ask you all the big brother who used this plastic building template ah? How is the quality of ah? So good ah?

- We use the pp building template. The effect is also good, top about. They also recycle the plastic building template we used for 3 tons for 1 ton.

- Q: Want to purchase a number of building templates and found a new plastic building template, do not know how the quality?

- Plastic construction template is the disadvantage of airtight and non-absorbent, in the mold, the wall will blister, can not meet the construction requirements, especially high-rise buildings, repeated use after a few times can no longer use. At present, a large number of domestic or wood template.

- Q: Who used plastic building templates? How is the effect? What are the advantages and disadvantages?

- Plastic construction template is not a good place to say, talk about the shortcomings of it, 1: the quality is too heavy, 2 intensity is not very satisfactory, 3, a little fee wooden side

- Q: Plastic mold dynamic template, the size of the template

- Bigger than the fixed model on the line, a good folder folder.

- Q: Why is the building template made 1830mm * 915mm and not made 2000mm * 1000mm it?

- This size is an international common size. Because more foreign use of foot units, 1 foot = 30.5cm, 1830 × 915 is usually said that the three or six feet board.

- Q: Shear wall plastic template for the wall height and thick ratio requirements is how much?

- Should not be less than 160mm, and should not be less than the floor of the high 1/20; bottom reinforced parts of the wall thickness of not less than 200mm, and should not be less than the floor of the high 16/1. Hope to be helpful to you.

Send your message to us

Plastic Concrete Formwork Accessories for Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 80000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords