tie rod spacer washers accessory for formwork

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

tie rod washers spacer for formwork

Concept

We are the professional supplier of formwork, scaffolding, couplers, prop, etc. As the leading supplier of modular formwork in North East China, we endeavour to help you build faster and conveniently, and most important, guarantee the safety for workers. We also endeavour to protect environment because we only have one earth.

Thanks to our credibility and high quality products, we have built long term cooperation relationship with many world class enterprises such as Saudi Arabia ATCO group, Russia Sakhalin Energy Investment Company, Italy Geoplast Company, etc.

Specifications

1. good seal, not leak concrete

2. sustainable and enviroment friendly

3. reusable

4. eco-friendly

5. easy operation

Product Description

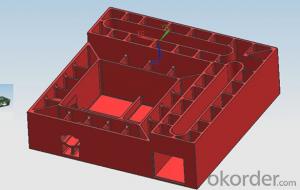

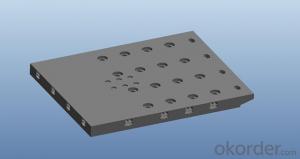

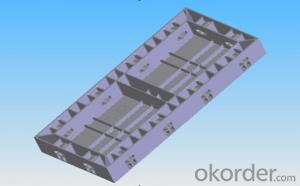

Tie rod, washers and spacers are the accessory for formwork system. Tie rod always used with washers, put tie rod through two formwork panels, and fasten by washers, this way to

strength the formwork system. The spacers used to provent the concrete leak thus make it easy to dismental the tie rod and washers, and then the tie rod and washers can be reused

hundreds of times.

Product Characteristics

| product name | tie rod/washers/spacer |

| origin | China |

| color | Black/yellow |

| material | nylon/steel |

| weight | 0.5kg |

| tensile strength | 40KN |

| brand | BOFU |

| reusable | 1000 times |

| model | CPANE0120 |

Product Introduction

Handier

The tie rod can be cut any length as customer like, generally 3m/pcs. One washers weight only 0.5kg, spacers can be cut as wall thickness.

easy set up

When using this system, just put through the tie rod to the formwork panels, and fasten it by washers, spacers cover the tie rod to prevent the concrete.

- Q: Who used it, how not universal.

- Strong plastic PP plastic template is a joint development of the company's patented product, is the national high-tech industrialization in 2000 to promote the project. The product is based on polypropylene, adding GF fiber, anti-aging additives made of a kind of engineering plastics. Is a plastic generation of steel (bamboo, wood) a new generation of building templates.

- Q: Does the building plastic template use it? How's the effect? Can I use 30 to 50 times? Can the fire protection requirements of the steel plate on the cast-in-place plate be achieved?

- I used, hand drawing is very convenient, can use hundreds of times, made of plastic

- Q: Europe and the United States national construction template is made of plastic or wood

- Part of the place with stones, as the case may be, but certainly yes, Europe and the United States have anti-seismic buildings

- Q: We have to start the construction site immediately, and have not used this plastic building template; I would like to ask you all the big brother who used this plastic building template ah? How is the quality of ah? So good ah?

- The production of plastic building template not only has the many advantages of plastic template, but also successfully broke the plastic building template price is high, the price is equivalent to the current construction industry commonly used bamboo sheet, while giving the plastic template more advantage.

- Q: Who used plastic building templates? How is the effect? What are the advantages and disadvantages?

- The main advantages are:1, the surface smooth and smooth, high strength, the provincial workers, the expected material, can meet the requirements of clear water concrete template, after stripping without cleaning the surface of the template, thus saving a lot of labor, template flatness can be controlled within 0.3mm, thickness uniformity, Can be controlled within ± 0.3mm, wood than the wood to save 2/3 of the nails.2, good water resistance, toughness, long-term immersion is not layered, water swelling rate of less than 0.06%, in -30 ℃ _ +60 ℃ range of normal use, the use of 6 years of aging of 15%, normal use of 8 Years or more.3, plasticity, according to the design and component size requirements, processing and production of different shapes and different specifications of the template, a curvature of the template for the production of a more simple template can be drilling nails, saws, planing and other wood mold with the same machinability , On-site stitching simple and convenient.4, recyclable use, plastic template to a certain extent can be fully recycled, regardless of the size of the old and new, after processing, can be added to produce a new template

- Q: Types of building templates? What is the water template?

- The type of template, according to the material to wood template, steel formwork, bamboo template, Gangmu combination template, etc.

- Q: Plastic mold dynamic template, the size of the template

- Did not you understand what you mean? The dimensions of the mold are based on your mold design, the more product positioning, the greater the shape of the mold.

- Q: How does the concrete on the plastic template remove (already glued to the concrete)

- Water, washed with water, rubbing with things, spend time slowly removed

- Q: Is there a kitchen toilet to seal the water pipe plastic template? Where to sell?

- With PVC board and steel ceiling of the board on it, to the hardware store to buy

- Q: Why is the building template made 1830mm * 915mm and not made 2000mm * 1000mm it?

- This size is an international common size. Because more foreign use of foot units, 1 foot = 30.5cm, 1830 × 915 is usually said that the three or six feet board.

Send your message to us

tie rod spacer washers accessory for formwork

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords