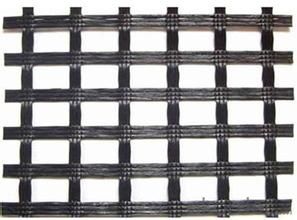

Reinforcement Geogrids - Fiberglass Geogrid Геосетк Длина Рулона Состав Пластик

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Geogrid With CE ISO certification

Геосетк Длина рулона, м 50 Разрывная нагрузка,

Intriduction:

CMAZ fiberglass georid is based on fiberglass woven cloth with modified bitumen or PVC, it was developed to address the problem of pavement cracing on highways, roads and runways, driven by a need to reduce cost for infrastructure maintanance and repair.

It is a characterized by high tensile strength in axial and lateral direcions,low stretch rate, alkali-resistance, low temperature-resistance, as well as convenience in construction and low price. It can be on pitch pavement to prevent cracks and prolong pavement service life. It also can be used as a basal reinforcement material for hillsides, reservoirs,harbors,ports,water channels,seawalls,etc.

Performance:

High strength, high modulus and low temperatures resistance.

Product function:

1. It reinforces old asphalt concrete road surface and asphalt surface layer, and prevents damage;

2. it used for rebuilding cement concrete road surface into composite road surface and restraining reflection caused by block contraction;

3. it is used in road expansion and improvement project and crack caused by old and new combination position and uneven sedimentation;

4. it is used in soft soil base reinforcement treatment ,is favorable for soft soil water separation and concretion, restrains sedimentation effectively, distributes stress uniformly and improve overall strength of road base;

5. it is used for preventing contraction crack caused by new road semi-rigid base layer, and reinforcing and preventing road surface crack caused by foundation crack reflection

| Tensile | Warp | ≥30 | ≥50 | ≥60 | ≥80 | ≥100 | ≥120 | ≥150 |

| Strength | ||||||||

| (KN) | Weft | ≥30 | ≥50 | ≥60 | ≥80 | ≥100 | ≥120 | ≥150 |

| Elogation | Fiberglass | <4 % | 4 % | 4 % | 4 % | 4 % | 4 % | 4 % |

| Polyester | <13%< td=""> | 13% | 13% | 13% | 13% | 13% | 13% | |

| Mesh size(mm) | 12.7×12.7 | 12.7×12.7 | 12.7×12.7 | 12.7×12.7 | 12.7×12.7 | 12.7×12.7 | 12.7×12.7 | |

| 25.4×25.4 | 25.4×25.4 | 25.4×25.4 | 25.4×25.4 | 25.4×25.4 | 25.4×25.4 | 25.4×25.4 | ||

| 42×42 | 42×42 | 42×42 | 42×42 | 42×42 | 42×42 | 42×42 | ||

| 50×50 | 50×50 | 50×50 | 50×50 | 50×50 | 50×50 | 50×50 | ||

| Elastic Modulus | 76 | 76 | 76 | 76 | 76 | 76 | 76 | |

| (Fiberglass) | ||||||||

| Width(m) | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | |

| Length(m) | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | |

| Temperature | Fiberglass | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 |

| Resistant (°C) | Polyester | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 |

| Resin | Fiberglass | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 |

| Content (%) | polyester | ≤30% | ≤30% | ≤30% | ≤30% | ≤30% | ≤30% | ≤30% |

- Q: How do geogrids enhance the stability of steep highway embankments?

- Geogrids enhance the stability of steep highway embankments by reinforcing the soil and preventing lateral movement. They provide tensile strength to the soil, distributing the load more effectively and reducing the potential for slope failure. Additionally, geogrids improve the overall bearing capacity of the embankment, enhancing its ability to withstand vertical and horizontal forces.

- Q: How do geogrids improve the performance of geosynthetic reinforced slopes?

- Geogrids improve the performance of geosynthetic reinforced slopes by providing reinforcement and stability to the soil. They enhance the tensile strength of the soil, preventing it from sliding or collapsing. Geogrids also distribute the load evenly across the slope, reducing stress concentrations and promoting better load-bearing capacity. Additionally, they facilitate better interlocking between soil particles, increasing the overall shear strength and resistance to erosion.

- Q: What are the physical properties of Geosynthetics

- What are the physical properties of geosynthetics? 1, thickness: the thickness of geosynthetics mm. The variation of thickness has a great influence on the porosity, permeability and filtration properties of the fabric. Commonly used the thickness of all kinds of geosynthetics: geomembrane 0.25 ~ 0.75mm, the thickest of up to 2 ~ 4mm;

- Q: Geogrid and geotextile, the role is the same?

- Geogrid and geotextile are different

- Q: How do geogrids enhance the performance of geotextile tubes?

- Geogrids enhance the performance of geotextile tubes by providing additional strength, stability, and reinforcement to the structure. They help distribute and transfer the loads more efficiently, improving the overall stability and resistance to deformation of the geotextile tubes.

- Q: How do geogrids improve the performance of geosynthetic-reinforced slopes in seismic zones?

- Geogrids improve the performance of geosynthetic-reinforced slopes in seismic zones by providing increased stability and reducing the potential for slope failure. These geosynthetic materials act as a reinforcement layer within the slope, distributing and dissipating the seismic forces more effectively. By enhancing the tensile strength and shear resistance of the slope, geogrids minimize the displacement and deformation during seismic events, thereby enhancing the overall stability and safety of the slope in seismic zones.

- Q: Can geogrids be used in reinforcement of soft soils?

- Yes, geogrids can be used in the reinforcement of soft soils. Geogrids are commonly used in civil engineering applications to stabilize and reinforce weak soils. They provide tensile strength and distribute loads, improving the overall stability and load-bearing capacity of the soil.

- Q: Are geogrids suitable for use in ground reinforcement for residential developments?

- Yes, geogrids are suitable for use in ground reinforcement for residential developments. They provide excellent soil stabilization and reinforcement, helping to prevent soil erosion, improve load-bearing capacity, and enhance the longevity of residential structures. Geogrids are a cost-effective and sustainable solution for various ground reinforcement applications, making them a suitable choice for residential developments.

- Q: How to determine the number of geogrid detection method

- What are the geogrid testing items1) place: in the surface layer of 50cm thick sand gravel or sand (egg) gravel cushion, and compaction, which is not only conducive to improve the friction between the soil and the grid, but also conducive to the consolidation of the foundation drainage.

- Q: How do geogrids improve the performance of geotextile tubes?

- Geogrids improve the performance of geotextile tubes by providing additional structural support and stability. They enhance the tensile strength of the geotextile tubes, preventing deformation and maintaining their shape under pressure. Geogrids also increase the overall load-bearing capacity of the geotextile tubes, making them more effective in erosion control, shoreline protection, and soil stabilization applications.

Send your message to us

Reinforcement Geogrids - Fiberglass Geogrid Геосетк Длина Рулона Состав Пластик

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords