Fiberglass Geogrid for Tunnel Reinforcement - Embedment Length of Geogrids

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Geogrid for Tunnel Reinforcement

Description Of Fiberglass Geogrid for Tunnel Reinforcement:

Fiberglass geogrid is based on fiberglass woven cloth coated with modified bitumen or PVC, it was developed to address the problem of pavement cracking on highways, roads and runways, driven by a need to reduce cost for infrastructure maintenance and repair.

It is characterized by high tensile strength in axial and lateral directions, low stretch rate, alkali-resistance, low temperature- resistance, as well as convenience in construction and low price. It can be used on pitch pavement to prevent cracks and prolong pavement service life. It also can be used as a basal reinforcement material for hillsides, reservoirs, harbors, ports, water channels, seawalls, etc.

Main Features of Fiberglass Geogrid for Tunnel Reinforcement:

1.High tensile strength, low elongation.

2.No long-term creep: the product can keep for a long time performance.

3.Thermal stability: fiber glass melting temperature above 1000 ℃.

4.The compatibility with asphalt.

5.Physical and chemical stability.

Specifications of Fiberglass Geogrid for Tunnel Reinforcement:

Tensile Strength (KN) | Warp | >30 | >50 | >60 | >80 | >100 | >120 | >150 | >200 |

Weft | >30 | >50 | >60 | >80 | >100 | >120 | >150 | >120 | |

Elongation(%) | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | <4< p=""> | |

Mesh Size(mm) | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | 25.4*25.4 | |

Elastic Modulus | 76 | 76 | 76 | 76 | 76 | 76 | 76 | 76 | |

Width(m) | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | 1~6 | |

Length(m) | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | 50~300 | |

Temperature Resistant(℃) | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | -100~280 | |

Resin Content (%) | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | 18~20 | |

Glue Type | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | Bitumen PVC SBR soakage | |

Applications of Fiberglass Geogrid for Tunnel Reinforcement:

Strengthen bitumen concrete roadway and reduce and prevent various kinds of reflection gaps on roadway.

1.Suitable for highway, railway, airport road of subgrade enhancement.

2.Suitable for the large parking lot and port freight yard that the foundations of the permanent load increased.

3.Suitable for railway, highway slope protection.

4.Suitable for culverts.

5.Suitable for the uniaxial tensile geogrid reinforced soil secondary enhancement, after further enhance soil, prevent soil erosion.

6.Mining, tunnel reinforcement.

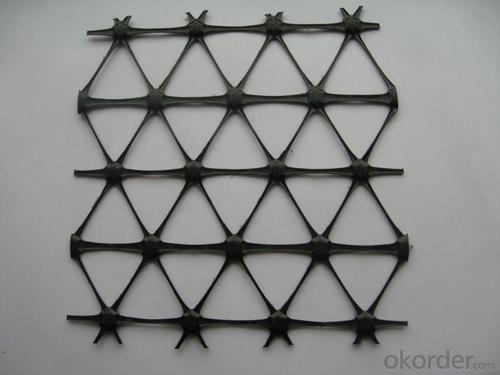

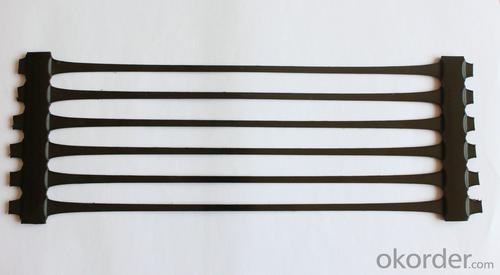

IMages of Fiberglass Geogrid for Tunnel Reinforcement:

FAQ of Fiberglass Geogrid for Tunnel Reinforcement:

1. What are we supplying?

We are specialized in producing Geosynthetic materials, like Geogrid Series, HDPE Geocell, Geonet, Geotextile, Geomat, Tri Denmensional Composite Grainage Geonet, and Geomembrane Series.

.

2. How Many years experience do we have?

We have been exported to more than 20 countries in the past 15 years.

3. How long do we usually reply your request?

We always reply our customer within 24 hours.

- Q: How do geogrids improve the performance of geocell-reinforced slopes?

- Geogrids improve the performance of geocell-reinforced slopes by providing additional strength and stability to the structure. They help distribute the load more evenly across the geocell system, preventing soil erosion and reducing the risk of slope failure. Geogrids also increase the overall tensile strength of the geocell-reinforced slope, making it more resistant to external forces such as water flow or seismic activity.

- Q: Can geogrids be used in soil stabilization for recreational areas?

- Yes, geogrids can be used in soil stabilization for recreational areas. Geogrids provide reinforcement and stabilization to the soil, preventing erosion and improving load-bearing capacity. This makes them suitable for various recreational applications, such as sports fields, playgrounds, and walking trails, ensuring a safe and durable surface for users.

- Q: History of geotechnical materials

- Geosynthetics are widely used in geotechnical engineering at present, which is a general name of polymer products. As early as in 1920s, the chemical industry was successful in the production of synthetic materials, but it was not until the late 50s that the material was gradually used as a new type of building materials to be used in geotechnical engineering. In the early stage, the products were mainly pervious to spinning and non-woven geotextiles, and later produced impermeable geomembrane. With the requirement of engineering practice and the improvement of manufacturing technology, the geogrid and other composite products with high strength reinforcement are manufactured. In this way, the original geotechnical fabric word has not summarized all kinds of products in the international meaning, so there are many alternative names, the geotextile material was the most common, but the habit still referred to as geotextile. Geotechnical material is divided into several categories of materials: geotextile, geomembrane, geogrid, drainage board, composite geomembrane, geotextile, geocell, bentonite waterproof blanket, etc..

- Q: What are the geotechnical testing items for Subgrade?

- Longitudinal and transverse tensile strength and elongation

- Q: What kind of experiments need to be done to check geogrid

- Or the same as the first inspection, different places are not the same as the results of some of the equipment testing may be out, but the probability is not. The company specializes in the production of Geogrid

- Q: Can geogrids be used in soil stabilization for agriculture?

- Yes, geogrids can be used in soil stabilization for agriculture. Geogrids are commonly used in various soil stabilization applications, including agriculture, to improve soil strength, prevent erosion, and enhance load-bearing capacity. They help in stabilizing the soil by providing reinforcement and distributing loads, which is essential for promoting healthy crop growth and preventing soil erosion in agricultural lands.

- Q: Can geogrids be used in stormwater management?

- Yes, geogrids can be used in stormwater management. Geogrids are commonly used in stormwater management systems to reinforce soil, stabilize slopes, and retain sediment. They provide excellent erosion control and can enhance the overall effectiveness of stormwater management practices.

- Q: How do geogrids enhance the performance of geosynthetic clay liner erosion control blankets?

- Geogrids enhance the performance of geosynthetic clay liner erosion control blankets by providing additional reinforcement and stability to the liner. They help distribute loads, reduce soil movement, and improve the overall performance of the erosion control system.

- Q: Glass fiber mesh and geogrid which is good

- All kinds of plastic geogrid, steel plastic composite geogrid, glass fiber geogrid, warp knitted polyester geogrid, geotextile composite geomembrane, bentonite waterproof blanket, a new 3D Geomat, geocell and other engineering materials

- Q: Can geogrids be used in ground reinforcement for airports?

- Yes, geogrids can be used in ground reinforcement for airports. Geogrids are commonly employed in the construction industry to reinforce and stabilize soil, including areas with heavy traffic such as airports. They can effectively distribute loads and improve the strength of the ground, ensuring the stability and durability required for airport infrastructure.

Send your message to us

Fiberglass Geogrid for Tunnel Reinforcement - Embedment Length of Geogrids

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords