Geotextile Fabric Reinforcement and Separation Fiberglass Geogrid for Muddy Roads

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Porducts Description

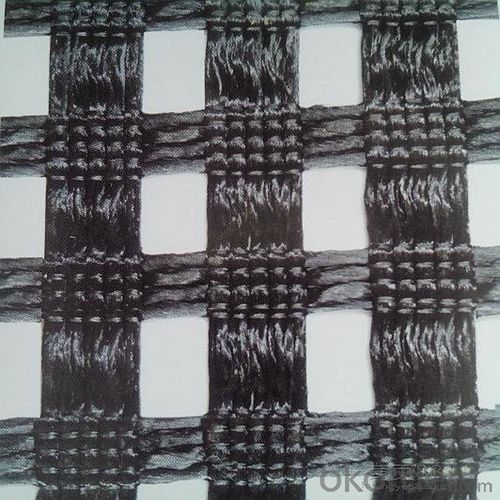

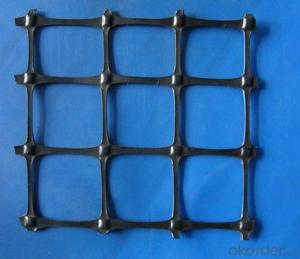

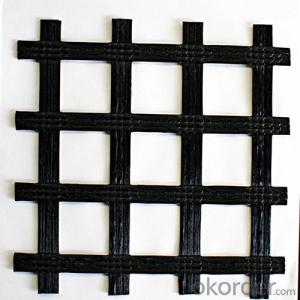

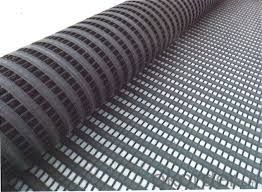

Classify Fiberglass Geogrid Classify Polyester Geogrid

Material Fiberglass Material Polyester

Tensile Strength: 25-25KN; 30-30KN; 50-50KN; 80-80KN; 100-100KN; 120-120KN;

Road Size: 3.95x100m; as customer required;

Application

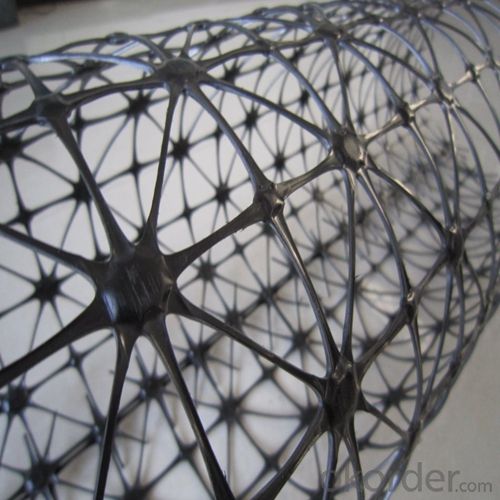

1. Roadbed reinforcement in highway, railway and municipal road, prevent road surface crack

2. Reinforcement and separation in dam and river, improve soft soil bearing capacity and stability.

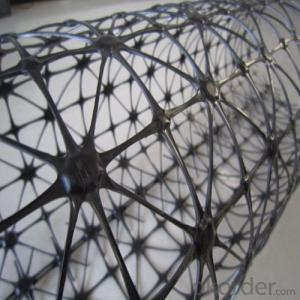

fiberglass geogrid/glass fiber geogrid with CE certificateIntroduction: Fiberglass geogrid is a kind of new favorable earthwork base material to strengthen the road surface and roadbed. This product is composed of fiberglass filaments that are coated with an inorganic sizing agent

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Artificial lake can not do geotextile waterproofing? What method can not do geotextile waterproof?

- Yes, with polyethylene polypropylene cloth is also OK

- Q: What are the key factors affecting the hydraulic conductivity of geotextiles?

- The key factors affecting the hydraulic conductivity of geotextiles include the size and shape of the geotextile fibers, the porosity of the material, the thickness of the geotextile, and the applied pressure or load. Other factors that can influence the hydraulic conductivity include the type of soil or aggregate being filtered, the presence of any clogging materials, and the overall condition and integrity of the geotextile.

- Q: Geotextile, one ton, replaced by a square meter how much money formula

- First look at how many grams of cloth, and then in addition to the number of square feet on how much money and then divided by the square to know how much money a square I plant geotextile

- Q: How do geotextiles help with soil reinforcement in retaining wall applications?

- Geotextiles help with soil reinforcement in retaining wall applications by providing a stable base for the wall, preventing soil erosion, and improving the overall stability and durability of the structure. They act as a barrier that separates the backfill soil from the wall, allowing for proper drainage while also preventing the loss of fine particles. This reinforcement helps to distribute the lateral forces exerted by the soil, reducing the pressure on the wall and increasing its overall strength.

- Q: The amount of geotextile drainage of the drainage pipe, as well as the amount of gravel block ye count

- Are you talking about plastic blinds? do you need? I specialize in producing geotextile materials

- Q: How are geotextiles different from other geosynthetic materials?

- Geotextiles are a type of geosynthetic material that is specifically designed to provide filtration, separation, and reinforcement functions in civil engineering projects. Unlike other geosynthetic materials such as geogrids or geomembranes, geotextiles are primarily used for their filtration properties, allowing water to pass through while retaining soil particles. They are typically made from synthetic fibers, which give them high tensile strength and durability. Overall, geotextiles serve a distinct purpose within geosynthetic materials, focusing on filtration and soil stabilization applications.

- Q: What are the design considerations for geotextile applications?

- Some design considerations for geotextile applications include the type and weight of the geotextile material, the strength and durability requirements, the expected level of permeability, the ability to withstand environmental conditions such as UV exposure or chemical exposure, and the compatibility with other materials used in the project. Additionally, factors such as installation methods, load distribution, and long-term maintenance should also be taken into account during the design process.

- Q: Can geotextiles be used in the construction of sports fields?

- Yes, geotextiles can be used in the construction of sports fields. Geotextiles are often used as a barrier between the soil and the playing surface to prevent weed growth, stabilize the soil, and improve drainage. They can also enhance the durability and longevity of the sports field by preventing soil erosion and reducing the risk of subsidence.

- Q: What is the difference between finished and semi-finished products?

- Think of ways to develop customers in the country Well. Foreigners may now also like, in the future may also like to like something else. We have the domestic people's own preferences are unable to control, but also control the other countries ah?

- Q: How do geotextiles help in stabilizing slopes for pipeline construction?

- Geotextiles help in stabilizing slopes for pipeline construction by providing reinforcement and erosion control. They are placed along the slope to prevent soil erosion and promote stability. The geotextiles act as a barrier, preventing the movement of soil particles and reducing the risk of slope failure. Additionally, they enhance the soil's strength and increase its resistance to erosion caused by water flow. Overall, geotextiles play a crucial role in maintaining the stability of slopes during pipeline construction.

Send your message to us

Geotextile Fabric Reinforcement and Separation Fiberglass Geogrid for Muddy Roads

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords