Embedment Length of Geogrids Reinforcement and Separation Geogrid for Civil Engineering Products

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

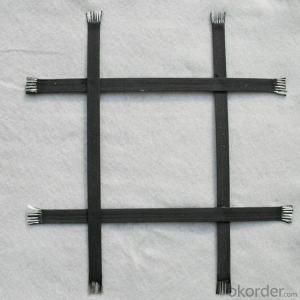

Geogrids are flat structures, where two or more series of strip elements made of polyester coated with polyethylene, are linked at regular intervals by means of bonding.

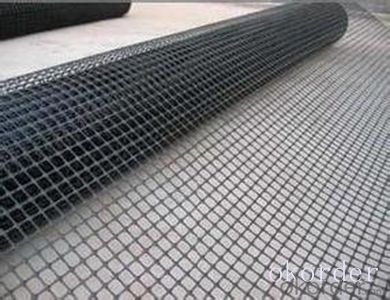

Woven Geogrids are flat structures in the shape of a net made of high module synthetic fibres20X20,30X30,40X40,50X50,60X60,70X70,80X80,90X90,

100X100KN

PP geogrid

20X20,30X30,40X40,50X50,60X60,70X70,80X80,90X90,

100X100,110x110KN

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: What is the role of Geogrid

- 4, geogrid used to reduce the thickness of cushion, save cost.5, the geogrid can effectively isolate the seismic force transfer, and to enhance the seismic stiffness, strength and stability of the embankment has an important role

- Q: Are geogrids effective in preventing soil erosion on slopes with vegetation?

- Yes, geogrids are effective in preventing soil erosion on slopes with vegetation. Geogrids provide structural support to the soil, preventing it from being washed away by water or blown away by wind. This helps to maintain the stability of the slope and protects the vegetation from being uprooted. Additionally, geogrids help to reinforce the root systems of plants, enhancing their ability to hold the soil in place. Overall, geogrids are a valuable tool in preventing soil erosion on slopes with vegetation.

- Q: Can geogrids be used in reinforcement of reinforced soil slopes?

- Yes, geogrids can be used in the reinforcement of reinforced soil slopes. Geogrids are commonly used in geotechnical engineering applications to enhance the stability and performance of soil structures, including reinforced soil slopes. They are typically placed within the soil mass to provide tensile strength and improve the overall resistance to soil movement. By effectively distributing and restraining the forces exerted on the soil slope, geogrids can significantly enhance its stability and prevent potential failures.

- Q: What is the recommended depth of geogrid installation?

- The recommended depth of geogrid installation can vary depending on the specific project and soil conditions. However, in general, it is recommended to install geogrids at a depth of at least 12 inches to provide adequate stabilization and reinforcement to the soil.

- Q: What are the design considerations for geogrid-reinforced slopes?

- Some of the design considerations for geogrid-reinforced slopes include the slope stability analysis, selection of appropriate geogrid material and properties, determining the required strength and stiffness of the geogrid, proper installation techniques, and considering the long-term durability and maintenance requirements of the reinforced slope.

- Q: How do geogrids improve the performance of geocell-reinforced slopes for erosion control?

- Geogrids improve the performance of geocell-reinforced slopes for erosion control by providing additional strength and stability. They help distribute the load evenly across the slope, preventing soil movement and reducing erosion. Additionally, geogrids increase the frictional resistance between soil layers, enhancing the overall slope stability and preventing soil slippage.

- Q: Is there any difference between glass fiber grille and geogrid

- There are many kinds of Geogrid

- Q: What are the factors that affect the installation and survivability of geogrids in harsh environments?

- There are several factors that can impact the installation and survivability of geogrids in harsh environments. Firstly, the quality and strength of the geogrid material itself play a significant role. Geogrids made from durable and high-quality materials are more likely to withstand harsh conditions. Secondly, the installation technique is crucial, as improper installation can lead to geogrids being damaged or dislodged. The type and condition of the subgrade also affect the geogrid's survivability, as a stable and well-prepared subgrade provides a solid foundation for the geogrids. Additionally, environmental factors such as extreme temperatures, moisture levels, and chemical exposure can impact the long-term performance and durability of geogrids in harsh environments.

- Q: Can geogrids be used in retaining walls?

- Yes, geogrids can be used in retaining walls. Geogrids are commonly used as a reinforcement material in retaining walls to enhance their stability and strength.

- Q: How many Chinese geogrid manufacturers? How many famous

- Manufacturers have more than N, there is no specific how much to say

Send your message to us

Embedment Length of Geogrids Reinforcement and Separation Geogrid for Civil Engineering Products

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords