Nysdot Approved Reinforcement and Separation Geogrids for Civil Engineering in Road Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction

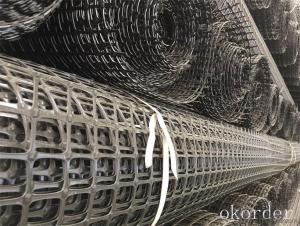

PET geogrid

15X15,20X20,25X25,30X30,35X35,40X40,50X50,60X60.

70X70,80X80,90X90,100X100,110X110KN

color:

black

certification:

ISO9001,ISO14001

standard:

GB/T 17639-2008

MOQ:

5000m2

Place of origin:

Shandong,China

packing:

according to customer's need

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: How do geogrids help in reducing construction labor requirements?

- Geogrids help in reducing construction labor requirements by providing stability and reinforcement to the soil, thus eliminating the need for extensive excavation and compaction. They distribute loads more evenly, reducing the amount of material needed and the labor involved in handling and compacting it. This ultimately leads to faster and more efficient construction processes with fewer workers required.

- Q: What are the types of Geogrid

- Glass fiber geogrid, 1595341 polyester fiber geogrid, glass fiber, polyester composite geotextile, steel plastic composite geogrid, PP grid, one-way two-way stretching plastic geogrid,

- Q: Is there a big difference between horizontal permeability and vertical permeability coefficient

- Geomembrane, composite geomembrane, geotextile, geogrid, geotextile, geotextile bags, etc. are called geosynthetics. The coefficient of permeability is a kind of soil properties;

- Q: Can geogrids be used in reinforcement of embankments over soft soils?

- Yes, geogrids can be used in the reinforcement of embankments over soft soils. Geogrids are commonly used to improve the stability and strength of embankments by providing additional reinforcement and distributing loads more evenly. By placing geogrids within the embankment layers, they can effectively improve the bearing capacity of the soil, prevent excessive settlement, and increase the overall stability of the embankment structure.

- Q: How do geogrids improve the performance of geotextile sediment retention systems?

- Geogrids improve the performance of geotextile sediment retention systems by providing reinforcement and stability. They enhance the overall strength and durability of the system, preventing soil erosion and retaining sediment effectively. Additionally, geogrids help distribute load and reduce stress on the geotextile, increasing its lifespan and effectiveness in retaining sediments.

- Q: Geogrid is mainly used for what?

- Application of unidirectional geogrid:Unidirectional geogrid is a kind of high strength structural material, which is suitable for highway, municipal road, railway, runway and so on. 1, strengthen the embankment, can effectively improve the load distribution, and the bearing capacity and service life of the subgrade stability; 2, preventing the material loss caused by the deformation of subgrade, and even rupture; 3, can withstand greater load; 4, applicable to all kinds of soil, no place to be drawn, saves time and labor; and the use of construction simple biaxial geogrid:

- Q: What is the road geogrid

- GeogridThe grid is made of polypropylene, polyvinyl chloride and other high molecular polymer thermoplastic or molded into a two-dimensional grid or a certain degree of three-dimensional grid screen, when used as civil engineering, known as the geogrid

- Q: Are there any environmental concerns associated with geogrids?

- Yes, there are some environmental concerns associated with geogrids. One concern is that geogrids are often made from non-biodegradable materials such as plastics, which can contribute to pollution and waste accumulation. Additionally, the manufacturing process of geogrids may require the use of fossil fuels and other resources, which can have a negative impact on the environment. However, when used correctly and in appropriate applications, geogrids can also help mitigate certain environmental concerns such as soil erosion and habitat destruction.

- Q: What are the quality control measures for geogrid manufacturing?

- Quality control measures for geogrid manufacturing typically include several steps and processes to ensure the product meets the required standards and specifications. These measures may include regular inspections and testing of raw materials, such as polymer resins, to ensure their quality and consistency. During the manufacturing process, strict monitoring is carried out to ensure proper mixing and blending of materials, as well as accurate temperature and pressure controls. Additionally, the geogrids are subject to various tests, including tensile strength, elongation, aperture size, and aperture stability tests, to verify their performance and durability. These quality control measures help ensure that the geogrids produced are of high quality and capable of meeting the intended engineering applications.

- Q: What are the long-term performance characteristics of geogrids?

- The long-term performance characteristics of geogrids include high tensile strength, durability, and resistance to creep or deformation over time. Geogrids also exhibit excellent resistance to chemical and biological degradation, making them suitable for long-term applications in various civil engineering and construction projects. Additionally, geogrids provide long-lasting reinforcement and stabilization to soils, helping to maintain their structural integrity and prevent soil erosion.

Send your message to us

Nysdot Approved Reinforcement and Separation Geogrids for Civil Engineering in Road Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords