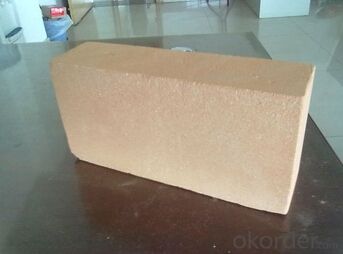

Insulating Fire Brick - Refractory Mullite Insulating Refractory Brick JM 28

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 20 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information

CMAX insulating firebricks are classified under temperature between 1300℃ to 1700℃, manufactured from high purity alumina clay.

1. Lower content of iron, alkaline and impurities, good high temperature properties.

2. Homogeneous structure, light weight, energy saving because lower heat storage in the furnace during cooling cycles.

3. High strength, good thermal shock resistance under high temperature.

4. Precise sizes due to grinding and shaping after sintering, which meets the requirement of construction.

5. Max service temp: Up to 1730C (3160F)

Feature

Light weight and low thermal conductivity

Low heat storage

Low iron and impurities

High thermal shock resistance

Application of Insulating brick

Metallurgical Industry: blast furnace, hot blast furnace, heating furnace, etc..

Petrochemical Industry: ethylene cracking furnace, hydrogen furnace, the main furnace, heating furnace, etc..

Ceramic industry: roller kiln, kiln, etc..

Glass industry: glass furnace regenerator, etc.

Carbon industry: carbon furnace, etc..

Aluminum electrolysis industry: aluminum reduction cell, etc.

Other industries: tunnel kiln, shuttle kiln, etc.

Advantages of heat insulation brick

Low thermal conductivity: many air holes will bring good thermal insulation effect, energy saving.

High crushing strength: high crushing strength, volume stability.

Low heat storage: small heat storage, absorb more heat, energy-saving effect is obvious.

Technical Data

ITEM | GJM30 | GJM28 | GJM26 | GJM23 |

Classification Temperature, ℉/℃ | 3000/1650 | 2800/1540 | 2600/1430 | 2300/1260 |

Bulk Density,g/cm³ | ≤1.0 | ≤0.9 | ≤0.8 | ≥0.5 |

Reheating Linear Change, % | ≤0.9 (1550℃,12 h) | ≤0.8 (1510℃,12 h) | ≤0.7 (1410℃,12 h) | ≤0.5 (1230℃,12 h) |

Al2O3 Content, % | ≥75 | ≥65 | ≥55 | ≥45 |

Fe2O3 Content, % | ≤0.5 | ≤0.6 | ≤0.7 | ≤1.0 |

Thermal Conductivity: | ||||

800℃, w/m.k | ≤0.39 | ≤0.37 | ≤0.35 | ≤0.18 |

1000℃, w/m.k | ≤0.43 | ≤0.41 | ≤0.39 | ≤0.20 |

1200℃, w/m.k | ≤0.48 | ≤0.46 | ≤0.43 | --- |

Insulating brick

Common problem solution

1. What products do you have?

We have all kinds of refractory bricks, refractory casting materials, mortar, cement, ceramic fiber products, etc..

Or you can browse our products to choose what you need.

2. How to control product quality?

With strict quality control system throughout the material selection and production process, we have the quality of refractory materials and ceramic fiber products to meet customer requirements.

From the selection of raw materials, the quality of our control to start. The quality of the raw materials required for each batch of products in the use of the front line test. In the production process, through the quality control of workers, and then to each piece of classification, and through quality supervision and inspection.

3. Could you give me a brief introduction to the application of your product?

My Company is mainly engaged in steel, cement, glass, ceramics, petrochemical, electric power and other industries.

4. If I need you, what kind of information do you need?

In order to select the right products, we will provide us with information, such as the United States, technical data, order quantity, product applications, etc..

If you have any questions, please contact us.

- Q: Can insulating fire bricks be used in the construction of lime recovery kilns?

- Insulating fire bricks are indeed applicable for the construction of lime recovery kilns. These kilns, utilized in industrial settings, operate at high temperatures to convert limestone into lime via calcination. Specifically designed to endure elevated temperatures and offer exceptional thermal insulation, insulating fire bricks are composed of lightweight refractory materials, such as clay or silica, and possess low thermal conductivity. Within lime recovery kilns, which can reach temperatures ranging from 900 to 1200 degrees Celsius, insulating fire bricks are suitable for lining the kiln's walls, floors, and roofs. Their superior insulating properties effectively diminish heat loss, thereby enhancing energy efficiency by retaining heat within the kiln. Consequently, this results in reduced fuel consumption and cost savings. Furthermore, insulating fire bricks exhibit excellent resistance to thermal shock, a crucial characteristic in the lime recovery process. These kilns undergo repeated cycles of heating and cooling, necessitating bricks capable of withstanding temperature fluctuations without cracking or disintegrating. Ultimately, insulating fire bricks prove to be a fitting choice for lime recovery kilns due to their capacity to withstand high temperatures, provide thermal insulation, and resist thermal shock.

- Q: Can insulating fire bricks be used as a lining for chimneys?

- Yes, insulating fire bricks can be used as a lining for chimneys. These bricks are designed to withstand high temperatures and provide insulation, making them suitable for lining chimneys and protecting them from heat damage.

- Q: Can insulating fire bricks be used in residential fireplaces?

- Yes, insulating fire bricks can be used in residential fireplaces. Insulating fire bricks are designed to withstand high temperatures and provide excellent insulation, making them a suitable choice for fireplace construction. These bricks can help retain heat, increase energy efficiency, and prevent heat loss. They also offer superior protection against thermal shock, which is essential for withstanding the intense heat generated by a fireplace. Additionally, insulating fire bricks are lightweight, easy to handle, and can be easily shaped or cut to fit any fireplace design or size. Overall, using insulating fire bricks in residential fireplaces is a wise choice for homeowners looking to enhance the performance and safety of their fireplace.

- Q: Can insulating fire bricks be used in wood-fired kilns?

- Indeed, wood-fired kilns can utilize insulating fire bricks. These bricks are specifically engineered to endure elevated temperatures and offer exceptional insulation, rendering them an optimal choice for wood-fired kilns. They effectively retain and evenly distribute heat throughout the kiln, guaranteeing efficient and uniform wood firing. Furthermore, their lightweight nature aids in the construction and upkeep of the kiln. Ultimately, the utilization of insulating fire bricks in wood-fired kilns enhances their overall performance and efficiency.

- Q: Are insulating fire bricks resistant to alkali attack?

- Yes, insulating fire bricks are generally resistant to alkali attack. These bricks are made from high-temperature refractory materials and are designed to withstand extreme temperatures and chemical environments. Alkalis are known to corrode and degrade certain materials, but insulating fire bricks are specifically formulated to resist this type of chemical attack. They have a low porosity and dense structure, which helps prevent the penetration of alkalis into the brick's surface. Additionally, the refractory materials used in these bricks have a high melting point and are chemically inert, making them well-suited for applications where alkali exposure is a concern. However, it is important to note that the specific resistance of insulating fire bricks to alkali attack may vary depending on the composition and manufacturing process of the brick, as well as the concentration and duration of alkali exposure. Therefore, it is always recommended to consult with the manufacturer or supplier for detailed information about the resistance of their specific insulating fire bricks to alkali attack.

- Q: Are insulating fire bricks suitable for use in the construction of lime kilns?

- Insulating fire bricks are indeed suitable for constructing lime kilns. These bricks are designed specifically to possess low thermal conductivity, enabling them to retain heat and avoid heat loss. This feature is crucial in lime kilns as they necessitate high temperatures for effectively converting limestone into lime. The utilization of insulating fire bricks facilitates the better maintenance of the kiln's generated heat, leading to enhanced energy efficiency and reduced fuel consumption. Moreover, these bricks are lightweight and convenient to handle, making them the perfect choice for lime kiln construction. All in all, insulating fire bricks are a dependable and efficient option for building lime kilns.

- Q: Can insulating fire bricks be used for insulation in heat recovery systems?

- Indeed, insulating fire bricks have the capability to serve as insulation within heat recovery systems. These bricks are specially crafted to endure elevated temperatures and deliver efficient thermal insulation. By possessing low thermal conductivity, they possess the ability to reduce heat dissipation and enhance heat recovery within a system. Consequently, they are frequently implemented in diverse industrial settings, including kilns, furnaces, and ovens, where temperature regulation and energy efficiency are paramount. Therefore, these bricks present a viable option for insulating heat recovery systems, facilitating the optimization of waste heat recovery and utilization.

- Q: Can insulating fire bricks be used in the construction of heat storage systems?

- Insulating fire bricks have the potential to be utilized in the construction of heat storage systems. These bricks are specifically designed to possess low thermal conductivity, enabling them to effectively trap and retain heat. They are typically composed of materials such as fire clay, which possess exceptional insulation properties. By incorporating insulating fire bricks, it becomes feasible to minimize heat loss, thereby facilitating efficient heat storage and retention within the system. These bricks can be employed to construct the walls and lining of the heat storage system, ensuring that the stored heat does not dissipate into the surroundings. Furthermore, insulating fire bricks are lightweight and easily manageable, rendering them a convenient option for the construction of heat storage systems. Ultimately, the utilization of insulating fire bricks significantly enhances the thermal efficiency of heat storage systems, consequently contributing to more effective heat management.

- Q: Can insulating fire bricks be used in the construction of lime production linings?

- Insulating fire bricks are capable of being utilized in the construction of lime production linings. These bricks are specifically designed to possess low thermal conductivity, making them exceptionally beneficial for applications that necessitate heat insulation. In the process of calcination that takes place during lime production, high temperatures are essential. By incorporating insulating fire bricks into the construction of lime production linings, heat loss can be minimized, thus enhancing energy efficiency. Furthermore, these bricks are lightweight and easy to manipulate, rendering them suitable for lining various components of lime kilns and other equipment employed in the lime production process. In summary, the utilization of insulating fire bricks in lime production linings has the potential to optimize the production process and enhance the overall performance of lime production facilities.

- Q: Can insulating fire bricks be used for insulation in steam pipes?

- Insulating fire bricks are indeed a viable choice for insulating steam pipes due to their exceptional ability to withstand high temperatures and provide excellent thermal insulation. With their low thermal conductivity, these bricks effectively impede heat transfer, making them perfect for insulating steam pipes. This quality aids in minimizing heat loss and maintaining the steam's temperature within the pipes. Furthermore, the lightweight nature and easy installation of insulating fire bricks make them a convenient option for insulating steam pipes.

Send your message to us

Insulating Fire Brick - Refractory Mullite Insulating Refractory Brick JM 28

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 20 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords