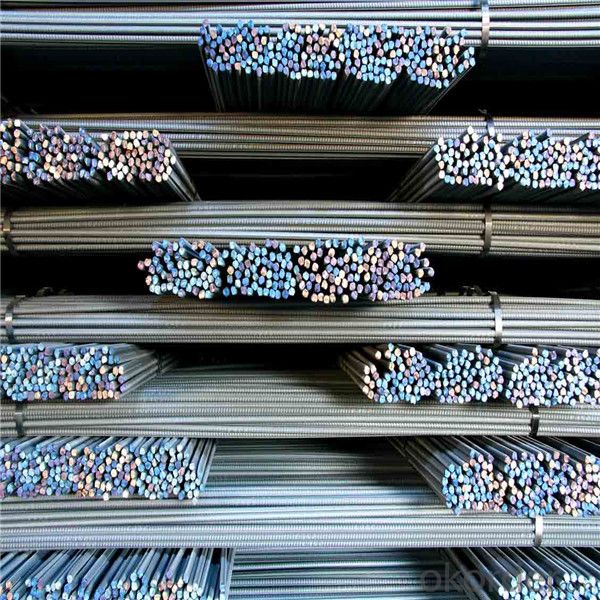

Rebar Strength Deformed Steel Iron Rods in Different Diameters

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 128362 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Our Advantage:

High quality steel products from 1 class mills in China

Reasonable price

Professionalism of the products

On-time delivery

Complete documents and certificates

Sincere service to meet our clients' requirements

Product Description :

Chemical composition (%): | Steel | C | Si | Mn | P | S | Ceq | ||||

HRB335 |

0.25 |

0.80 |

1.60 |

0.045 |

0.045 | 0.52 | |||||

HRB400 | 0.54 | ||||||||||

HRB500 | 0.55 | ||||||||||

Mechanical properties | Steel | Rel/ MPa | Rm/ MPa | A/ % | Agt/ % | ||||||

≥ | |||||||||||

HRB335 | 335 | 455 | 17 |

7.5 | |||||||

HRB400 | 400 | 540 | 16 | ||||||||

HRB500 | 500 | 630 | 15 | ||||||||

Package: | Standard export packing or as customer's request | ||||||||||

Application: | Construction, building, bridge, road. ect | ||||||||||

Payment terms | 1).100% irrevocable L/C at sight. | ||||||||||

Delivery time | 15-30 days after receipt of L/C or deposit by T/T | ||||||||||

Features

1、Pure steel quality, stable chemical contents, small tolerance.

2、Constant Quality, good drawing performance.

3、High dimension accuracy degree, accuracy degree of Level C up to 80%, smooth surface, less scale, easy to be pickled.

4、Automatic bundling with 4 lines by Machine in tidy and good looks

5、Big high quality percentage, small coil percentage, and heavy coil weight for Hard Coil.

6、High sorbitizing percentage.

Packing:

In bundles, each bundle weight 3.5 tons. Load by container or by bulk verssel.

Our service

(1) We cooperate with famous factories with advanced equipment and well trained workers.

(2) We can provide factory price with trading company service.

(3) We continuously work on the improvement of our processes, guaranteeing consistently high standards

of quality to keep none compensation.

(4) We guarantee 24 hours response and 48 hours solution providing service.

(5) We accept small order quantity before formal cooperation.

(6) We deliver the agreed quality at the agreed time, reacting to changes in customer wishes in a flexible way.

(7) Due to our volume and selling power, we have excellent freight rates with shipping lines.

(8) We strive to always be fair and honest in our dealings with customers.

(9) We strive to work together with customers to achieve much more than we can achieve alone.

(10) Through our passion and commitment we aim to be a market leader in all our key markets. To maintain

our position as market leader we must continue to add value in all that we do.

FAQ:

1.Q: What's your MOQ(minimum order quantity)?

A: One full container, mixed acceptable .

2. Q: What's your packing methods?

A: Packed in bundle or bulk ..

3. Q: How can I buy CNBM products in my country?

A:Please send us an inquiry or email ,we will reply to you if there is distributor in your country

4. Q: Can we visit your factory?

A: Warmly welcome. Once we have your schedule, we will arrange the professional sales team to follow up your case.

5. Q: How long does it take to get the product if i place an order?

A:With the process of your requirements,we will pack and deliver in 3-7 days. If it is by sea shipment,it will take 15-45 days depending on different locations

- Q:Can steel rebars be used in structures with limited foundation support?

- Yes, steel rebars can be used in structures with limited foundation support. Steel rebars are commonly used as reinforcement in concrete structures to enhance their strength and durability. They can help distribute the load more evenly across the structure, which can be particularly beneficial in situations where there is limited foundation support. However, it is important to assess the specific circumstances and consult with a structural engineer to ensure that the design and placement of the rebars are appropriate for the given foundation conditions.

- Q:What is the process of calculating the required quantity of steel rebars for a project?

- The process of calculating the required quantity of steel rebars for a project involves several key steps. Firstly, you need to determine the design requirements and specifications of the project. This includes understanding the structural drawings, plans, and any relevant building codes or regulations. Next, you need to identify the specific areas where steel rebars will be used. This can include foundations, columns, beams, slabs, and any other structural elements that require reinforcement. Once the areas are identified, you need to calculate the total length of rebars required for each element. This is done by measuring the dimensions of the elements and determining the required spacing and overlap of the rebars. After obtaining the lengths, you need to consider the bar diameter and spacing requirements, as specified in the design. This will help you calculate the number of rebars needed for each element. In addition to the length and number of rebars, you also need to consider wastage and additional reinforcement requirements. It is common practice to add a percentage of wastage (usually around 2-5%) to account for cutting and bending of the rebars. You may also need to add extra bars for special conditions or to meet the design requirements. Finally, you should create a detailed bar bending schedule (BBS) that includes all the necessary information such as bar sizes, lengths, shapes, and placement details. This schedule acts as a guide for the construction team during the installation process. It is important to note that the process of calculating the required quantity of steel rebars may vary depending on the complexity and size of the project. It is recommended to consult with a structural engineer or a professional rebar detailer to ensure accurate calculations and adherence to the project's specifications.

- Q:Can steel rebars corrode or rust over time?

- Yes, steel rebars can corrode or rust over time due to exposure to moisture and oxygen.

- Q:How are steel rebars bundled and tied together on construction sites?

- Steel rebars, which are commonly used in construction sites to reinforce concrete structures, are bundled and tied together using a specific technique called rebar tying. This process ensures that rebars remain secure and in place during concrete pouring and other construction activities. To bundle rebars, construction workers typically gather a predetermined number of rebars, depending on the project's requirements, and align them parallel to each other. They then use wire or steel straps to tightly bind the rebars together, forming a bundle. The wire or steel straps are wrapped around the rebars at regular intervals, ensuring that the bundle remains compact and the rebars do not shift or separate. Once the rebars are bundled, they are further secured by tying them together using specialized tools. The most common tool used for rebar tying is a rebar tying gun or a rebar tier. This tool automates the process of tying rebars by quickly and efficiently twisting wire around the rebars, creating tight and secure connections. Rebar tying guns or tiers are equipped with a spool of wire that is fed through the tool. The construction worker simply positions the tool over the rebars, presses a trigger or button, and the tool automatically twists the wire around the rebars, tying them together. This process is repeated at regular intervals along the length of the rebars to ensure that they are securely fastened together. The type of wire used for rebar tying is typically a thin, high-tensile steel wire that is strong enough to withstand the forces exerted on the rebars during construction. This wire is specifically designed for rebar tying and is available in pre-cut lengths or on spools. Overall, the bundling and tying of steel rebars on construction sites is a crucial step in ensuring the structural integrity of concrete structures. The use of wire or steel straps, along with specialized rebar tying tools, allows construction workers to create secure and tightly bound bundles of rebars, preventing any movement or separation during construction activities.

- Q:How do steel rebars affect the overall fire rating of a building?

- Steel rebars can have a positive impact on the overall fire rating of a building. By reinforcing concrete structures, rebars can help enhance the fire resistance of the building. Steel has high melting and ignition temperatures, which means it can withstand heat and maintain its structural integrity for longer periods during a fire. This additional durability provided by rebars can help prevent structural collapse, allowing occupants more time to evacuate safely and aiding firefighters in their efforts to suppress the fire.

- Q:How do steel rebars affect the shrinkage and creep behavior of concrete?

- Steel rebars can significantly affect the shrinkage and creep behavior of concrete. Shrinkage refers to the contraction of concrete as it dries and hardens, while creep refers to the long-term deformation of concrete under sustained load. The presence of steel rebars in concrete can reduce the overall shrinkage of the concrete due to two main reasons. Firstly, the steel rebars provide a restraint against shrinkage by resisting the tensile forces that develop during drying. This restraint reduces the overall volume change of the concrete, minimizing the shrinkage. Secondly, the rebars also act as a barrier to moisture movement, limiting the drying and shrinkage of the concrete. However, the addition of steel rebars can also influence the creep behavior of concrete. Creep is influenced by the modulus of elasticity and the strength of the material, and the presence of steel rebars can alter these properties. The high modulus of elasticity and strength of steel rebars can cause the concrete to experience higher levels of creep due to the differential deformation between the concrete and the steel. Moreover, the bond between the rebars and the concrete also plays a role in affecting the creep behavior. The bond strength between the rebars and the concrete can influence the transfer of stress from the concrete to the rebars, affecting the overall creep behavior of the composite material. In summary, steel rebars can reduce the shrinkage of concrete by providing restraint against drying and minimizing moisture movement. However, they can also influence the creep behavior of concrete due to their modulus of elasticity, strength, and the bond between the rebars and the concrete. Understanding the interaction between steel rebars and concrete is crucial in designing structures that can withstand shrinkage and creep effects.

- Q:Can steel rebars be used in precast concrete applications?

- Yes, steel rebars can be used in precast concrete applications. They provide structural reinforcement to the precast concrete elements, enhancing their strength and durability.

- Q:What are the different types of steel coatings used on rebars?

- There are several types of steel coatings commonly used on rebars, including epoxy, galvanized, and stainless steel.

- Q:Why is the price of screw steel affected by iron ore and coal?

- Just now the manufacturing needs to consume iron ore and gas energy, the cost goes up, the price certainly changes

- Q:How do steel rebars affect the constructability of complex architectural designs?

- Steel rebars play a crucial role in the constructability of complex architectural designs by providing structural reinforcement and stability. They enable architects to create intricate and ambitious designs, as rebars can be manipulated and bent to fit various shapes and forms. This flexibility allows for the construction of complex structures, such as curved or cantilevered designs, that would otherwise be challenging or impossible to achieve. Additionally, steel rebars enhance the durability and longevity of buildings, ensuring their ability to withstand various loads and forces over time.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Rebar Strength Deformed Steel Iron Rods in Different Diameters

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 128362 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords