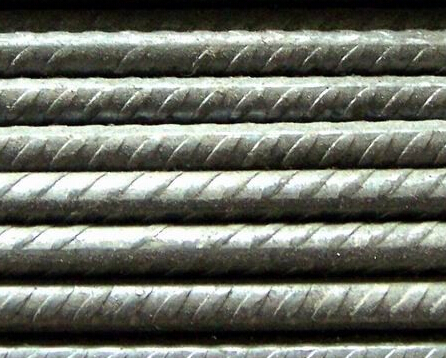

Deformed Steel Bar ASTM A615 GR40 GR60 with High Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Deformed Steel Bar ASTM A615 GR40 GR60 with High Quality at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Deformed Steel Bar ASTM A615 GR40 GR60 with High Quality are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Steel I-Beams are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Specifications of Deformed Steel Bar ASTM A615 GR40 GR60 with High Quality:

Standard | GB | HRB335, HRB400, HRB500 | |

UK | G460B, B500A, B500B,B500C | ||

USA | GR40, GR60 | ||

Diameter | 6mm,8mm,10mm,12mm,14mm,16mm,18mm,20mm, 22mm,25mm,28mm,32mm,36mm,40mm,50mm | ||

Length | 6M, 9M,12M or as required | ||

Place of origin | Hebei, China mainland | ||

Application | building,construction,road,bridge etc | ||

Brand name | DRAGON | ||

Theoretical weight and section area of each diameter as below for your information:

Diameter(mm) | Section area (mm²) | Mass(kg/m) |

6 | 28.27 | 0.222 |

8 | 50.27 | 0.395 |

10 | 78.54 | 0.617 |

12 | 113.1 | 0.888 |

14 | 153.9 | 1.21 |

16 | 201.1 | 1.58 |

18 | 254.5 | 2.00 |

20 | 314.2 | 2.47 |

22 | 380.1 | 2.98 |

25 | 490.9 | 3.85 |

28 | 615.8 | 4.83 |

32 | 804.2 | 6.31 |

36 | 1018 | 7.99 |

40 | 1257 | 9.87 |

50 | 1964 | 15.42 |

Usage and Applications of Deformed Steel Bar ASTM A615 GR40 GR60 with High Quality:

Deformed bar is widely used in buildings, bridges, roads and other engineering construction. Big to highways, railways, bridges, culverts, tunnels, public facilities such as flood control, dam, small to housing construction, beam, column, wall and the foundation of the plate, deformed bar is an integral structure material. With the development of world economy and the vigorous development of infrastructure construction, real estate, the demand for deformed bar will be larger and larger..

Packaging & Delivery of Deformed Steel Bar:

Packaging Detail: products are packed in bundle and then shipped by container or bulk vessel, deformed bar is usually naked strapping delivery, when storing, please pay attention to moisture proof. The performance of rust will produce adverse effect.

Each bundle weight: 2-3MT, or as required

Payment term: TT or L/C

Delivery Detail: within 45 days after received advanced payment or LC.

Label: to be specified by customer, generally, each bundle has 1-2 labels

Trade terms: FOB, CFR, CIF

Deformed Steel Bar in Coil

Produce Line of Deformed Steel Bar

Note:

1. Our products are produced according to national standard (GB), if not, supply according to national standards (GB) or agreement as customer required.

2. Other Grade and Standard Deformed Steel Bar we can supply:

Grade: GR40/GR60, G460B/B500A/B500B/B500C,BST500S

Standard: ASTM, BS, DIN

The Minimum Order Quantity of these products is high, and need to be confirmed.

3. We can not only supply Deformed Steel Bar; if you need anything about building materials, please contact us for further information.

4. Please send us your detail specifications when inquire. We will reply to you as soon as possible. We sincerely hope we can establish a long stable business relationship

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

- Q: What is the role of steel rebars in roof slab construction?

- Steel rebars are commonly used in roof slab construction to provide reinforcement and strength to the concrete. They help to distribute the load evenly across the slab, making it more resistant to bending and cracking. The rebars also help to prevent the concrete from expanding or contracting due to temperature changes, ensuring the stability and durability of the roof slab.

- Q: What are the guidelines for protecting steel rebars in structures exposed to aggressive chemicals?

- The guidelines for protecting steel rebars in structures exposed to aggressive chemicals typically include using corrosion-resistant materials such as epoxy-coated rebars or stainless steel rebars, applying protective coatings on the rebars, ensuring proper concrete cover thickness, and implementing regular inspections and maintenance to identify and address any signs of corrosion.

- Q: Can steel rebars be used in slabs and beams?

- Yes, steel rebars can be used in slabs and beams. Steel rebars are commonly used as reinforcement in concrete structures, including slabs and beams, to enhance their strength and durability.

- Q: Can steel rebars be used in corrosive environments?

- No, steel rebars are not suitable for use in corrosive environments as they are prone to corrosion and can weaken over time.

- Q: What are the guidelines for the proper curing of concrete with steel rebars?

- The proper curing of concrete with steel rebars requires adherence to the following guidelines: 1. Moisture: To ensure proper hydration and strength development, it is necessary to maintain moisture during the curing process. However, excessive moisture should be avoided when curing concrete with steel rebars to prevent corrosion and damage. Therefore, it is important to strike a balance between providing sufficient moisture and preventing the accumulation of standing water around the rebars. 2. Covering: During the pouring process, it is crucial to adequately cover the steel rebars with concrete to protect against corrosion. The thickness of the cover should meet the design specifications to ensure adequate strength and durability. 3. Curing time: The curing time for concrete with steel rebars is typically longer than that of plain concrete. This is due to the need for the steel to bond with the concrete and achieve proper adhesion. The recommended curing period may vary depending on factors such as ambient temperature, humidity, and the specific type of steel used. It is important to refer to the project specifications or consult with a structural engineer to determine the appropriate curing time for the specific application. 4. Temperature control: Temperature control is essential during the curing process to ensure uniform hydration and prevent thermal stress. Rapid temperature changes can lead to cracking and compromise the integrity of the concrete. Therefore, it is important to protect the concrete from extreme temperature variations and provide insulation or shading as necessary. 5. Protection from external elements: Concrete with steel rebars must be safeguarded against external elements that can cause damage or corrosion. This includes protection from chloride ions, carbonation, and chemicals. Additional protection can be provided by applying suitable surface coatings or sealants. 6. Inspection and maintenance: Regular inspection and maintenance are vital for ensuring the long-term durability of concrete with steel rebars. It is important to monitor for signs of corrosion, cracking, or deterioration and take appropriate action promptly. This may involve repairing damaged areas, applying protective coatings, or implementing measures to prevent corrosion. By following these guidelines, the proper curing of concrete with steel rebars can be achieved, resulting in a construction material that is structurally sound and durable, capable of withstanding the test of time.

- Q: Can steel rebars be used in the construction of educational institutions and schools?

- Yes, steel rebars can be used in the construction of educational institutions and schools. Steel rebars are commonly used as reinforcement in concrete structures, including educational buildings. They provide strength and durability to the structure, ensuring its safety and longevity. Additionally, steel rebars are fire-resistant, corrosion-resistant, and have high tensile strength, making them suitable for constructing educational institutions and schools.

- Q: What is the average lifespan of a reinforced concrete structure with steel rebars?

- The average lifespan of a reinforced concrete structure with steel rebars can vary depending on various factors such as the quality of construction, maintenance, exposure to environmental conditions, and usage patterns. However, with proper design, construction, and maintenance, reinforced concrete structures with steel rebars can have an average lifespan of 50 to 100 years or more. Reinforced concrete structures are known for their durability and strength due to the combination of concrete and steel reinforcement. The concrete provides compressive strength, while the steel rebars provide tensile strength, making the structure resistant to various loads and forces. However, over time, reinforced concrete structures may experience degradation due to factors such as exposure to moisture, chemicals, temperature changes, and loading conditions. These factors can lead to the corrosion of steel rebars, which is a common concern for the longevity of such structures. Corrosion occurs when moisture and oxygen penetrate the concrete, causing the steel rebars to rust. This rusting process can lead to the expansion of the steel rebars, causing cracks in the concrete and further accelerating the deterioration of the structure. To mitigate the effects of corrosion and extend the lifespan of reinforced concrete structures, various measures can be taken. These include using high-quality concrete and steel rebars, applying protective coatings, implementing proper drainage systems, and conducting regular inspections and maintenance. With appropriate maintenance and upkeep, reinforced concrete structures can last well beyond their average lifespan. However, it is crucial to note that the lifespan can vary depending on specific conditions and circumstances. Therefore, it is essential to consult with structural engineers and industry professionals to assess and determine the expected lifespan of a particular reinforced concrete structure.

- Q: What is the role of steel rebars in basement wall construction?

- The role of steel rebars in basement wall construction is to provide reinforcement and strength to the concrete walls. The rebars are embedded within the concrete to help resist tension and prevent cracking, ensuring the stability and durability of the basement walls.

- Q: How do steel rebars impact the overall flexibility of a structure?

- Steel rebars impact the overall flexibility of a structure by providing reinforcement and increasing its strength. The addition of steel rebars enhances the structural integrity, allowing the structure to withstand external forces and stresses without deformation or failure, thus improving its overall flexibility and durability.

- Q: How are steel rebars affected by temperature fluctuations?

- Steel rebars are affected by temperature fluctuations in several ways. Firstly, when exposed to high temperatures, steel rebars can expand, which may lead to the bending or distortion of the structure they support. On the other hand, in cold temperatures, steel rebars contract, potentially causing cracks or fractures in the concrete surrounding them. Rapid and frequent temperature changes can accelerate these effects, increasing the risk of structural damage. Therefore, it is crucial to consider temperature fluctuations when designing and constructing structures using steel rebars.

Send your message to us

Deformed Steel Bar ASTM A615 GR40 GR60 with High Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords