Rebar Sales Near Me:High Quality Deformed Steel Bar HRB400 Made in China

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Construction High Quality Deformed Steel Bar HRB400 MADE IN CHINA:

Standard | GB UK USA | HRB335 HRB400 HRB500 G460B, B500A, B500B,B500C GR40, GR60 | |

Diameter | 6mm,8mm,10mm,12mm,14mm,16mm,18mm,20mm, 22mm,25mm,28mm,32mm,36mm,40mm,50mm | ||

Length | 6M, 9M,12M or as required | ||

Packing | Export standard packing: wrapped by wire rod in bundles | ||

Each bundle weight | 2-3MT, or as required | ||

Inspection | Accept the third party inspection | ||

Type | Hot rolled steel rebar | ||

Brand name | DRAGON | ||

Chemical Composition: (Please kindly find our chemistry of our material based on BS4449 as below for your information)

BS4449 G460B | Chemical Composition | ||||

C | Mn | Si | S | P | |

0.18 | 0.35 | 0.14 | 0.025 | 0.25 | |

Physical capability | |||||

Yield Strength(N/cm²) | Tensile Strength(N/cm²) | Elongation (%) | |||

625 | ≥460 | 18 | |||

BS4449 500B | Chemical Composition | ||||

C | Mn | Si | S | P | |

0.24 | 0.45 | 0.16 | 0.05 | 0.31 | |

Physical capability | |||||

Yield Strength(N/cm²) | Tensile Strength(N/cm²) | Elongation (%) | |||

650 | ≥500 | 19 | |||

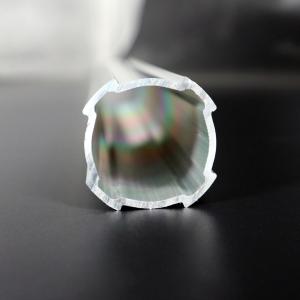

Deformed Steel Rebar in factory

Usage and Applications of High Quality Deformed Steel Bar HRB400 MADE IN CHINA:

Deformed bar is widely used in buildings, bridges, roads and other engineering construction. Big to highways, railways, bridges, culverts, tunnels, public facilities such as flood control, dam, small to housing construction, beam, column, wall and the foundation of the plate, deformed bar is an integral structure material. With the development of world economy and the vigorous development of infrastructure construction, real estate, the demand for deformed bar will be larger and larger..

Packaging & Delivery of High Quality Deformed Steel Bar HRB400 MADE IN CHINA:

Packaging Detail: products are packed in bundle and then shipped by container or bulk vessel, deformed bar is usually naked strapping delivery, when storing, please pay attention to moisture proof. The performance of rust will produce adverse effect.

Payment terms: TT payment in advance or Irrevocable LC at sight.

Trade terms :FOB, CFR, CIF

Delivery Detail: within 45 days after received advanced payment or LC.

Note:

1. Our products are produced according to national standard (GB), if not, supply according to national standards (GB) or agreement as customer required.

2. Other Grade and Standard Deformed Steel Bar we can supply:

Grade: GR40/GR60, G460B/B500A/B500B/B500C,BST500S

Standard: ASTM, BS, DIN

The Minimum Order Quantity of these products is high, and need to be confirmed.

3. We can not only supply Deformed Steel Bar; if you need anything about building materials, please contact us for further information.

4. Please send us your detail specifications when inquire. We will reply to you as soon as possible. We sincerely hope we can establish a long stable business relationship.

- Q:Can steel rebars be used in parking garage construction?

- Yes, steel rebars can be used in parking garage construction. Steel rebars are commonly used in reinforced concrete structures, including parking garages, to provide additional strength and durability. Rebars help to distribute the load and enhance the structural integrity of the concrete, making it capable of withstanding heavy loads, such as those encountered in parking garages. The use of steel rebars in parking garage construction is essential for ensuring the longevity and safety of the structure.

- Q:How are steel rebars connected to each other?

- Steel rebars are typically connected to each other using various methods such as overlapping, welding, or using mechanical connectors like couplers or threaded bars.

- Q:How do steel rebars affect the crack width in reinforced concrete?

- Steel rebars can help to control and limit crack width in reinforced concrete structures. The presence of rebars provides reinforcement and increases the tensile strength of the concrete. This enhanced strength helps to distribute and redistribute the stresses caused by loads, reducing the likelihood and width of cracks forming in the concrete. Additionally, the rebars act as a barrier, preventing cracks from propagating and limiting their width.

- Q:Can steel rebars be used in reinforced masonry structures?

- Yes, steel rebars can be used in reinforced masonry structures. They are commonly used to provide additional strength and reinforcement to masonry walls and structures, helping to resist tensile forces and improve overall structural integrity.

- Q:What are the different corrosion protection methods for steel rebars?

- There are several corrosion protection methods available for steel rebars, which are commonly used in reinforced concrete structures. These methods aim to prevent or minimize the corrosion of the steel rebars, as corrosion can significantly weaken the overall structure. 1. Concrete Cover: The most common corrosion protection method is providing an adequate thickness of concrete cover over the steel rebars. The concrete acts as a physical barrier, preventing exposure of the rebars to corrosive elements. 2. Galvanization: Galvanizing involves coating the steel rebars with a layer of zinc. This protective layer acts as a sacrificial anode, corroding before the steel rebars. Galvanization significantly enhances the rebars' resistance to corrosion. 3. Epoxy Coating: Epoxy coating is a popular corrosion protection method where a layer of epoxy resin is applied over the steel rebars. The epoxy acts as a barrier, preventing moisture and corrosive substances from reaching the rebars. 4. Cathodic Protection: Cathodic protection is an electrochemical method that involves the application of a sacrificial anode or an impressed current system. In a sacrificial anode system, a more reactive metal, such as zinc or magnesium, is connected to the steel rebars, sacrificing itself and preventing corrosion. In an impressed current system, an external power source is used to provide a protective current to the rebars, preventing corrosion. 5. Corrosion Inhibitors: Corrosion inhibitors are chemicals added to the concrete mix or applied as a surface treatment to the rebars. These inhibitors form a protective film on the rebars' surface, preventing corrosion by blocking the access of corrosive agents. 6. Stainless Steel Rebars: Using stainless steel rebars is an effective corrosion protection method. Stainless steel has a high resistance to corrosion, making it suitable for structures exposed to aggressive environments. It is important to note that the selection of the appropriate corrosion protection method depends on various factors, including the environmental conditions, expected service life of the structure, and cost considerations. Additionally, regular inspection and maintenance of the corrosion protection system are essential to ensure its effectiveness over time.

- Q:What is the effect of welding on the properties of steel rebars?

- The effect of welding on the properties of steel rebars can vary depending on various factors such as the welding process, parameters, and the quality of the weld. Generally, welding can introduce localized heat, which may lead to changes in the microstructure and mechanical properties of the rebars. These changes can include the formation of a heat-affected zone (HAZ) with altered hardness, strength, and toughness. Additionally, the weld itself may have different properties compared to the base metal, such as lower ductility or higher susceptibility to cracking. Therefore, it is crucial to carefully control the welding process and ensure proper welding techniques to minimize any adverse effects on the rebars' properties.

- Q:Can steel rebars be prefabricated off-site?

- Yes, steel rebars can be prefabricated off-site. Prefabrication involves manufacturing and assembling components, including rebars, in a controlled environment away from the construction site. This method offers numerous advantages, such as improved quality control, reduced construction time, and increased efficiency. Prefabricated steel rebars can be customized, cut, bent, and welded to meet specific project requirements before being transported to the construction site for installation.

- Q:Do steel rebars have any specific markings or codes?

- Yes, steel rebars typically have specific markings or codes to indicate their size, type, and grade. These markings are essential for identifying and ensuring the correct usage of rebars in construction projects.

- Q:What is the role of steel rebars in the construction of water storage tanks?

- Steel rebars play a crucial role in the construction of water storage tanks as they provide structural reinforcement and enhance the overall strength and stability of the tank. These rebars are embedded within the concrete walls of the tank, helping to distribute and resist the forces exerted by the weight of the water and any external pressure. Thus, by reinforcing the concrete, steel rebars ensure that the water storage tank can withstand the required load and remain durable and safe over time.

- Q:Can steel rebars be used in railway and transportation infrastructure?

- Yes, steel rebars can be used in railway and transportation infrastructure. Steel rebars, also known as reinforcing bars, are commonly used in the construction industry to provide strength and support to concrete structures. In railway and transportation infrastructure, where robust and durable structures are required, steel rebars are often used to reinforce concrete elements such as bridge piers, abutments, and retaining walls. The use of steel rebars in railway and transportation infrastructure offers several advantages. Firstly, steel rebars enhance the tensile strength of concrete, making the structures more resistant to the dynamic and heavy loads imposed by trains and vehicles. This is particularly important in bridges and elevated structures where the loads can be significant. Secondly, steel rebars provide structural integrity and prevent the development of cracks and deformations in the concrete. This is crucial for maintaining the long-term stability and safety of the infrastructure, especially considering the constant exposure to various environmental conditions, such as temperature variations and vibrations. Furthermore, steel rebars are highly durable and resistant to corrosion, which is essential in railway and transportation infrastructure that is often exposed to harsh weather conditions and chemical agents. Their ability to withstand these factors ensures the longevity of the structures and reduces the need for frequent repairs and maintenance. In conclusion, steel rebars can and are commonly used in railway and transportation infrastructure due to their ability to enhance the strength, durability, and stability of concrete structures. Their use ensures the safe and reliable operation of these vital transportation systems, providing a solid foundation for the efficient movement of people and goods.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Rebar Sales Near Me:High Quality Deformed Steel Bar HRB400 Made in China

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords