Hot Rolled Steel Rebar

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25MT m.t.

- Supply Capability:

- 800000TONS/YEAR m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Hot Rolled Steel Rebar:

Standard | GB UK USA | HRB335 HRB400 HRB500 G460B, B500A, B500B,B500C GR40, GR60 | |

Diameter | 6mm,8mm,10mm,12mm,14mm,16mm,18mm,20mm, 22mm,25mm,28mm,32mm,36mm,40mm,50mm | ||

Length | 6M, 9M,12M or as required | ||

Price | Keep lower operating costs so as to offer competitive price for our clients | ||

Delivery Detail | within 45 days after received advanced payment or LC. | ||

Application | mainly used in construction industry to reinforce concrete structures and so on | ||

Invoicing | Actual or Theoretical Weight Basis as buyer’s request. | ||

Type | Hot rolled steel rebar | ||

Brand name | DRAGON | ||

Theoretical weight and section area of each diameter as below for your information:

Diameter(mm) | Section area (mm²) | Mass(kg/m) | Weight of 12m (kg) | Pcs/ton |

6 | 28.27 | 0.222 | 2.664 | 375.38 |

8 | 50.27 | 0.395 | 4.74 | 210.97 |

10 | 78.54 | 0.617 | 7.404 | 135.06 |

12 | 113.1 | 0.888 | 10.656 | 93.84 |

14 | 153.9 | 1.21 | 14.52 | 68.87 |

16 | 201.1 | 1.58 | 18.96 | 52.74 |

18 | 254.5 | 2.00 | 24 | 41.67 |

20 | 314.2 | 2.47 | 29.64 | 33.74 |

22 | 380.1 | 2.98 | 35.76 | 27.96 |

25 | 490.9 | 3.85 | 46.2 | 21.65 |

28 | 615.8 | 4.83 | 57.96 | 17.25 |

32 | 804.2 | 6.31 | 75.72 | 13.21 |

36 | 1018 | 7.99 | 98.88 | 10.43 |

40 | 1257 | 9.87 | 118.44 | 8.44 |

50 | 1964 | 15.42 | 185.04 | 5.40 |

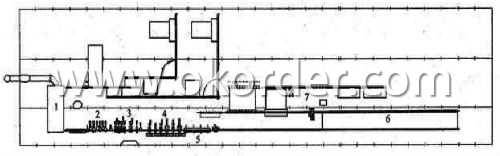

The production process of Steel Rebar

1-Waling beam furnace 2-Roughing rolling group 3-Intermediate rolling train

4-Finishing rolling group 5-Water-cooling device 6-Walking beam cooler

7-Finishing equipment(including the cold scale shear,short feet collection system,

automatic counting device,bundling machine, collect bench)

Usage and Applications of Hot Rolled Steel Rebar:

Deformed bar is widely used in buildings, bridges, roads and other engineering construction. Big to highways, railways, bridges, culverts, tunnels, public facilities such as flood control, dam, small to housing construction, beam, column, wall and the foundation of the plate, deformed bar is an integral structure material. With the development of world economy and the vigorous development of infrastructure construction, real estate, the demand for deformed bar will be larger and larger..

Packaging & Delivery of Hot Rolled Steel Rebar:

Packaging Detail: products are packed in bundle and then shipped by container or bulk vessel, deformed bar is usually naked strapping delivery, when storing, please pay attention to moisture proof. The performance of rust will produce adverse effect.

Each bundle weight: 2-3MT, or as required

Payment terms: TT payment in advance or Irrevocable LC at sight.

Trade terms :FOB, CFR, CIF

Label:to be specified by customer, generally, each bundle has 1-2 labels

Steel Rebar in stock

Note:

1. Our products are produced according to national standard (GB), if not, supply according to national standards (GB) or agreement as customer required.

2. Other Grade and Standard Deformed Steel Bar we can supply:

Grade: GR40/GR60, G460B/B500A/B500B/B500C,BST500S

Standard: ASTM, BS, DIN

The Minimum Order Quantity of these products is high, and need to be confirmed.

3. We can not only supply Deformed Steel Bar; if you need anything about building materials, please contact us for further information.

4. Please send us your detail specifications when inquire. We will reply to you as soon as possible. We sincerely hope we can establish a long stable business relationship.

- Q: What are the common misconceptions about steel rebars?

- Steel rebars are often mistakenly thought to be exclusively used in large construction projects. While they are indeed commonly employed in the construction of big buildings, bridges, and other infrastructure, they are also utilized in smaller endeavors such as residential homes, retaining walls, and even garden structures. By providing strength and reinforcement to concrete structures, rebars ensure the durability and longevity of these constructions. Another misconception pertains to the assumption that all rebars are identical. In reality, there are numerous types of rebars available, each possessing unique characteristics and serving specific purposes. Some common variations include carbon steel rebars, epoxy-coated rebars, stainless steel rebars, and galvanized rebars. The particular type selected depends on factors such as the environment, exposure to corrosive elements, and project requirements. Additionally, there is a misconception that rebars can be haphazardly placed or spaced within a concrete structure. However, improper placement or inadequate spacing of rebars can result in structural weaknesses, compromising the integrity of the concrete. It is essential to adhere to engineering specifications and guidelines to ensure that the rebars are correctly positioned and spaced, thus providing optimal reinforcement. Furthermore, there is a belief that steel rebars are prone to rusting. While it is accurate that steel can corrode when exposed to moisture and oxygen, construction practices can greatly mitigate this risk. For instance, the use of epoxy-coated or galvanized rebars offers an additional layer of protection against corrosion. Additionally, appropriate concrete cover and the application of protective coatings can prevent moisture penetration and prolong the lifespan of the rebars. Lastly, some individuals argue that steel rebars are costly and not cost-effective. Although it is true that steel rebars can contribute to the overall expenses of a construction project, they are an indispensable investment in ensuring structural integrity and safety. The cost of repairing or replacing a structure due to insufficient reinforcement far exceeds the initial investment in quality rebars. Furthermore, the use of rebars can reduce the need for excessive concrete, resulting in cost savings in terms of materials and construction time. In conclusion, it is imperative to debunk prevailing misconceptions surrounding steel rebars. They are not solely limited to large construction projects, they come in various types, necessitate proper placement and spacing, can be safeguarded against corrosion, and represent a cost-effective investment in guaranteeing the durability and safety of concrete structures.

- Q: Can steel rebars be used in parking garage construction?

- Indeed, steel rebars find their application in the construction of parking garages. Reinforced concrete structures, such as parking garages, frequently employ steel rebars to augment their robustness and resilience. By distributing the load and bolstering the structural integrity of the concrete, rebars enable it to withstand substantial weights typically encountered in parking garages. The incorporation of steel rebars into parking garage construction is indispensable to ensure the enduring longevity and safety of the edifice.

- Q: What is the effect of steel rebars on the formwork design?

- The presence of steel rebars in formwork design provides structural reinforcement and improves the overall strength and durability of the structure. The rebars help distribute the load and forces more effectively, allowing for the creation of thinner and lighter formwork designs. Additionally, steel rebars can be used to reinforce specific areas or joints where additional strength is required. Overall, incorporating steel rebars in formwork design enhances the structural integrity and longevity of the construction project.

- Q: Are there any limitations on using steel rebars in cold climates?

- Yes, there are some limitations on using steel rebars in cold climates. The main concern is the potential for corrosion due to the presence of moisture, salt, and de-icing chemicals commonly used on roads and bridges during winter. When steel rebars are exposed to these elements, they can rust and weaken over time, compromising the structural integrity of the concrete. To mitigate this issue, several measures can be taken. One common practice is to use epoxy-coated rebars, which provide a protective layer against moisture and chemicals. Additionally, stainless steel rebars can be used, as they are highly resistant to corrosion. However, these options can be more expensive than traditional steel rebars. Furthermore, the construction process in cold climates can also present challenges. Concrete cures and gains strength more slowly in low temperatures, which can impact the overall project timeline. Special precautions, such as heating the concrete or using accelerators, may be necessary to ensure proper curing. It is important to consult local building codes and regulations specific to cold climates to ensure compliance and safety. Engineering professionals experienced in cold weather construction practices can provide valuable insights and recommendations to address the limitations associated with using steel rebars in these conditions.

- Q: How are steel rebars stored on-site?

- Steel rebars are typically stored on-site in a horizontal position, either on racks or on elevated platforms, to prevent contact with the ground and minimize the risk of corrosion. They are often organized by size and type, and protected from the elements through the use of waterproof covers or tarps. Additionally, rebars should be kept away from moisture and excessive heat to maintain their structural integrity.

- Q: What are the guidelines for proper spacing and lapping of steel rebars in concrete structures?

- The guidelines for proper spacing and lapping of steel rebars in concrete structures vary depending on the specific design and structural requirements. However, some general recommendations exist. The rebars should be adequately spaced to ensure proper concrete cover, allowing for corrosion protection and sufficient bond strength. Typically, the minimum spacing between parallel rebars is around 1.5 times the diameter of the larger bar or 25 mm (1 inch), whichever is greater. Lapping, or overlapping, of rebars is necessary to create a continuous load path. The length of the overlap depends on the design and the type of rebar connection being used. It is important to follow the specifications provided by structural engineers and adhere to local building codes to ensure the proper spacing and lapping of rebars in concrete structures.

- Q: What are the benefits of using stainless steel rebars?

- There are several benefits of using stainless steel rebars in construction projects. Firstly, stainless steel rebars offer excellent corrosion resistance. This is particularly important in environments with high humidity, coastal areas, or projects where the concrete will be exposed to water or chemicals. Unlike traditional carbon steel rebars, stainless steel rebars do not rust or corrode easily, ensuring the long-term integrity and durability of the structure. Secondly, stainless steel rebars have a higher tensile strength compared to carbon steel rebars. This means that they can withstand greater forces and stresses without deforming or breaking. This makes stainless steel rebars ideal for structures that require high load-bearing capacity, such as bridges, parking garages, and high-rise buildings. Furthermore, stainless steel rebars have a low thermal expansion coefficient. This means that they do not expand or contract significantly with changes in temperature. This property helps to minimize cracking and structural damage due to thermal stresses, ensuring the longevity and stability of the concrete structure. In addition to their mechanical properties, stainless steel rebars are also aesthetically pleasing. With their sleek and shiny appearance, stainless steel rebars can enhance the visual appeal of architectural elements such as exposed concrete walls or features in bridges and buildings. Lastly, stainless steel rebars are environmentally friendly. They are 100% recyclable, making them a sustainable choice for construction projects. By using stainless steel rebars, builders and engineers can contribute to reducing the carbon footprint and promoting a greener construction industry. Overall, the benefits of using stainless steel rebars include superior corrosion resistance, high tensile strength, low thermal expansion, aesthetic appeal, and environmental sustainability. These advantages make stainless steel rebars a preferred choice for various construction applications, providing long-lasting and reliable reinforcement for concrete structures.

- Q: What is the impact of steel rebars on the overall sustainability of a building?

- Steel rebars have a significant impact on the overall sustainability of a building. The use of steel rebars in construction enhances the structural integrity and longevity of a building, reducing the need for frequent repairs and replacements. This, in turn, contributes to the sustainable aspect of a building by minimizing resource consumption and waste generation. Moreover, steel is a highly recyclable material, allowing for a circular economy approach in construction. By incorporating steel rebars, buildings can achieve higher energy efficiency, reduced environmental footprint, and enhanced durability, thus positively impacting their overall sustainability.

- Q: How do steel rebars contribute to the overall architectural design of a structure?

- Steel rebars contribute to the overall architectural design of a structure by providing crucial reinforcement and strength to concrete. They help to distribute and bear the load, enhancing the structural integrity and durability of the building. Additionally, rebars allow for the creation of more complex architectural designs, as they can be shaped and configured to meet specific structural requirements.

- Q: What is the impact of steel rebars on the overall sustainability of a structure?

- Steel rebars have a significant impact on the overall sustainability of a structure. As a key component in reinforced concrete, steel rebars enhance the structural integrity and durability of buildings, bridges, and other infrastructure. Their high tensile strength allows for the construction of tall and robust structures, reducing the need for additional materials. Additionally, steel rebars can be recycled, minimizing their environmental footprint and promoting a circular economy. This recyclability not only conserves natural resources but also reduces greenhouse gas emissions associated with steel production. Consequently, steel rebars play a vital role in creating sustainable and long-lasting structures.

1. Manufacturer Overview

| Location | Hebei, China |

| Year Established | 2009 |

| Annual Output Value | Above US$ 500 Million |

| Main Markets | Southeast Asia; East Asia; Middle east |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; |

| Export Percentage | 40%-60% |

| No.of Employees in Trade Department | 21-60 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 850,000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM service offered |

| Product Price Range | high; average |

Send your message to us

Hot Rolled Steel Rebar

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25MT m.t.

- Supply Capability:

- 800000TONS/YEAR m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords