Ral 9016 SGCC Color Coated PPGI Steel Coil Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

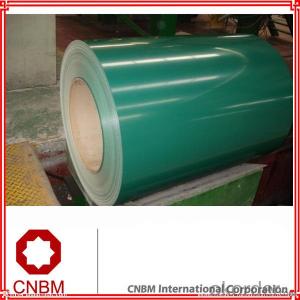

Ral 9016 SGCC Color Coated PPGI Steel Coil Price

Description of Ral 9016 SGCC Color Coated PPGI Steel Coil Price

Product | PPGI/PPGL |

Capacity | 5,000 tons/month |

Base material | Hot dipped galvanized steel |

Thickness | 0.2-2.0mm |

Width | 600-1250mm(according to your need) |

Coil Weight | 3-6tons |

Quality | SGCC, DX51D |

Color | RAL No. or customers samples’ color |

Zinc-coating | 30g/m2-180g/m2 |

Coil ID | 508mm/610mm |

Technique | Cold rolled—hot dipped galvanized—color coated |

Painting | Top painting:15~25μm |

Back painting: 6~10μm | |

Tolerance | Thickness: +/-0.02mm |

Width:+/-2mm | |

Shipment time | within 15-45 workdays |

Payment | T/T, L/C at sight |

Packing | Standard export packing |

The special order can be negotiated. | |

Application of Ral 9016 SGCC Color Coated PPGI Steel Coil Price

APPLICATION OF OUR PREPAINTED STEEL | ||||||||||

Construction | Outside | Workshop,agricultural warehouse,residential precast unit | ||||||||

corrugated roof,roller shutter door,rainwater drainage pipe,retailer booth | ||||||||||

Inside | Door,doorcase,light steel roof stucture,folding screen,elevator,stairway,ven gutter,Construction Wall | |||||||||

Electrical applicance | Refrigerator,washer,switch cabnet,instrument cabinet,air conditioning,micro-wave owen,bread maker | |||||||||

Fuiniture | Central heating slice,lampshade,chifforobe,desk,bed,locker,bookself | |||||||||

Carrying trade | Exterior decoration of auto and train,clapboard,container,isolation lairage,isolation board | |||||||||

Qthers | Writing panel,garbagecan,billboard,timekeeper,typewriter,instrument panel,weight sensor,photographic equipment | |||||||||

Products Show of Ral 9016 SGCC Color Coated PPGI Steel Coil Price

Product Advantages

1.With nearly 20 years experience in prepainted steel, accommodate different marketdemands. | ||||||||||||||

2.'Quality first, service first' is our business aim; 'The good faith get respect,cast quality market' is our Business philosophy . | ||||||||||||||

3.Having two series producttion line,with the abbual production capacity of 240000 tons. | ||||||||||||||

4.Exceed International ISO9001:2008&ISO14001:2004 quality and environmental standards | ||||||||||||||

5.Meet with ROHS standard |

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

F A Q

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: How is shock-resistant alloy steel used in the production of impact-resistant parts?

- Shock-resistant alloy steel is used in the production of impact-resistant parts due to its unique properties that make it highly resistant to deformation and fracture under high impact loads. The alloy steel's composition includes elements such as chromium, nickel, and molybdenum, which enhance its toughness and durability. These properties allow the alloy steel to absorb and disperse the energy generated during impact, effectively protecting the parts from damage. Additionally, the shock-resistant alloy steel's high strength enables it to withstand repeated impacts without losing its structural integrity, making it an ideal material for manufacturing impact-resistant parts used in various industries, including automotive, aerospace, and construction.

- Q: What are the properties of alloy steel?

- Alloy steel is a type of steel that is made by combining iron with other elements, such as carbon, manganese, nickel, or chromium. It possesses unique properties that make it highly desirable for various applications. Some of the properties of alloy steel include high strength, excellent toughness, good corrosion resistance, and enhanced wear resistance. Additionally, alloy steel can be easily machined and welded, allowing for greater flexibility in its usage. The specific properties of alloy steel can vary depending on the particular elements added to it, leading to a wide range of alloys with different characteristics.

- Q: What are the properties of wear-resistant tool steel?

- Wear-resistant tool steel is characterized by its high hardness, strength, and resistance to abrasion and wear. It has a high carbon content, typically ranging from 0.7% to 1.5%, which contributes to its hardness and wear resistance. This type of steel is also known for its ability to retain its hardness even at high temperatures, making it suitable for applications that involve friction and heat. Additionally, wear-resistant tool steel usually exhibits good toughness and machinability, allowing it to withstand heavy usage and be easily shaped into various tool forms.

- Q: What are the different heat treatment methods used for special steel?

- Special steel undergoes various heat treatment methods, each serving its own purpose and offering unique advantages. These methods are employed to enhance the mechanical properties of the steel, including hardness, toughness, and strength. Some commonly used heat treatment methods for special steel are as follows: 1. Annealing: By heating the steel to a specified temperature and holding it there for a specific duration, followed by gradual cooling, annealing reduces internal stress and improves the steel's machinability. 2. Normalizing: This process involves heating the steel above its critical range and allowing it to cool in still air. Normalizing refines the grain structure, resulting in a more uniform steel with improved strength and toughness. 3. Quenching: Rapid cooling through immersion in a quenching medium, such as oil or water, after heating the steel to a specific temperature, results in hardened steel with increased hardness and wear resistance. 4. Tempering: After hardening the steel, reheating it to a specific temperature and then cooling it in still air reduces brittleness and improves toughness and ductility. 5. Austempering: In this specialized method, the steel is quenched to a temperature just above its martensite transformation range and held there for a specific duration, followed by air cooling. Austempering produces steel with a combination of high strength and toughness. 6. Martempering: This variation of quenching and tempering involves quenching the steel and then holding it slightly above its martensite transformation range before air cooling. Martempering improves toughness and reduces distortion. 7. Nitriding: By heating the steel in an atmosphere of ammonia gas, nitrogen is introduced, resulting in a hard nitride layer on the surface. Nitriding increases hardness, wear resistance, and corrosion resistance. These heat treatment methods play a crucial role in tailoring the properties of special steel to meet specific requirements in industries such as automotive, aerospace, and tool manufacturing. The choice of heat treatment method depends on the desired properties and the intended application of the steel.

- Q: How does special steel perform in terms of weldability?

- Special steel generally performs well in terms of weldability. It is specifically designed to have good weldability characteristics, which means it can be easily welded without much difficulty or the need for specialized welding techniques. This makes it a preferred choice for many welding applications, as it allows for efficient and reliable joining of different components or structures.

- Q: Can special steel be used in high-pressure applications?

- Yes, special steel can be used in high-pressure applications. Special steel alloys, such as stainless steel or high-strength low-alloy steel, possess excellent mechanical properties and resistance to corrosion, making them suitable for withstanding high-pressure environments. These steels can maintain their structural integrity and perform reliably under extreme pressure conditions, making them a preferred choice in various industries, including oil and gas, aerospace, and chemical processing.

- Q: Can special steel be used in corrosive environments?

- Yes, special steel can be used in corrosive environments. Special steels like stainless steel and corrosion-resistant alloys are specifically designed to withstand corrosion and maintain their structural integrity in harsh and corrosive environments such as marine, chemical, or industrial settings. These steels contain additional alloying elements like chromium, nickel, or molybdenum, which provide enhanced corrosion resistance properties, making them suitable for use in corrosive environments.

- Q: What are the different casting methods used for special steel?

- For special steel, various casting methods are commonly utilized, depending on the specific requirements and needs of the application. These methods encompass investment casting, sand casting, continuous casting, and centrifugal casting. 1. Investment casting: To create the desired part, a wax pattern is made and coated with a ceramic shell. The wax is melted away, leaving a hollow shell that is then filled with molten steel. After solidification, the ceramic shell is broken, yielding the final part. Investment casting enables the production of accurate and intricate shapes, making it ideal for high-quality and precise special steel components. 2. Sand casting: Among the oldest and most prevalent casting techniques, sand casting involves forming a mold using a mixture of sand and a binder like clay. The mold is shaped around a pattern of the desired part and molten steel is poured into it. Upon cooling and solidification, the casting is complete. Sand casting is versatile and cost-effective, suitable for producing large and heavy special steel components. 3. Continuous casting: This method is commonly employed for manufacturing long steel products such as bars, rods, and billets. Molten steel is continuously poured into a water-cooled mold, which solidifies the outer surface. The solidified steel is then continuously withdrawn as more molten steel is poured in. Continuous casting ensures high-quality steel with a consistent cross-section, devoid of defects. 4. Centrifugal casting: In this technique, molten steel is poured into a rotating mold. The centrifugal force drives the molten steel towards the outer walls, resulting in a dense and compact casting with enhanced mechanical properties. Centrifugal casting is particularly suitable for producing cylindrical or tubular special steel components such as pipes and rings. In summary, the selection of a casting method for special steel hinges on factors like part complexity, required quality and accuracy, component size and shape, and production volume. Each method has its advantages and limitations, necessitating careful consideration to determine the most appropriate casting technique for a specific application.

- Q: How is special steel used in the manufacturing of industrial machinery?

- Special steel is used in the manufacturing of industrial machinery due to its exceptional properties such as high strength, durability, and resistance to corrosion. It is commonly utilized in components like gears, shafts, bearings, and tooling, as it can withstand heavy loads, high temperatures, and harsh working conditions. By using special steel, manufacturers can ensure the reliability and longevity of industrial machinery, enhancing overall performance and productivity.

- Q: What is the tensile strength of special steel?

- The tensile strength of special steel can vary depending on its specific composition and manufacturing process. However, special steel is generally known for its high tensile strength, often exceeding 1000 MPa (mega pascals), making it suitable for applications requiring strong and durable materials.

Send your message to us

Ral 9016 SGCC Color Coated PPGI Steel Coil Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords