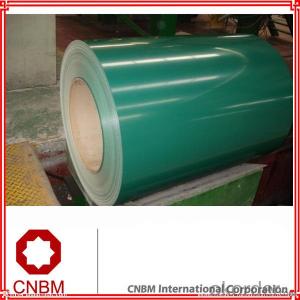

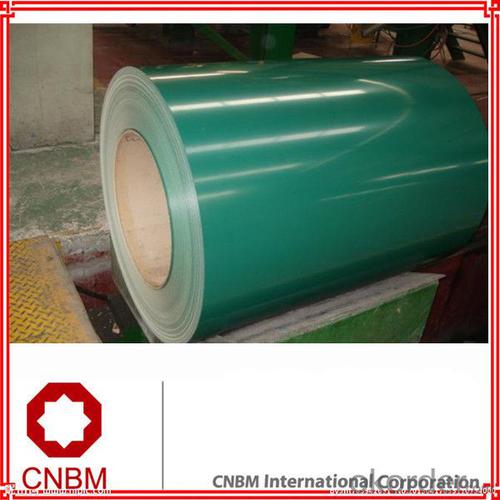

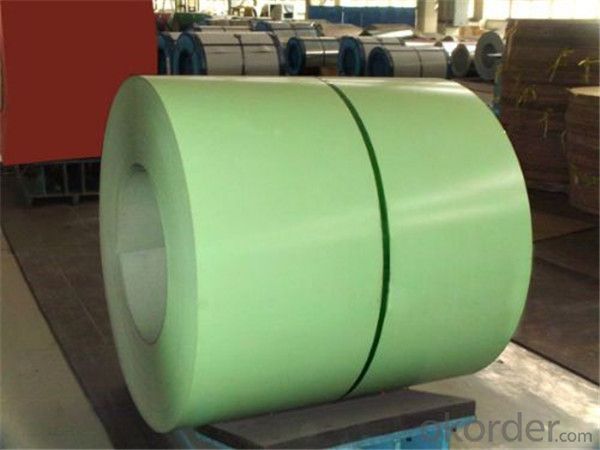

Ral 5016 color coated steel coil wholesale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 24234 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Ral 5016 color coated steel coil wholesale

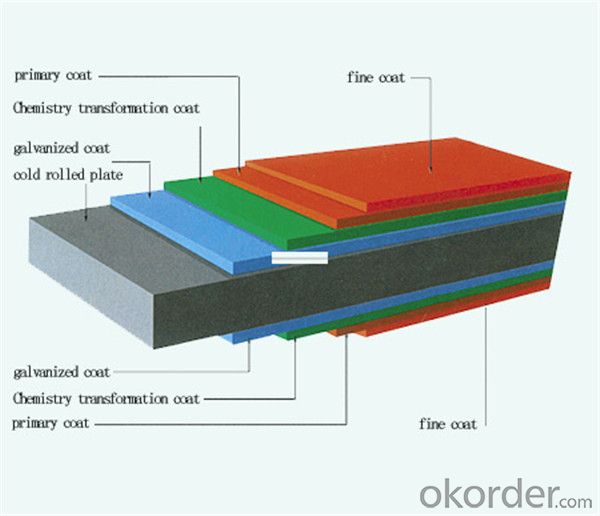

Prepainted steel sheet /coil is coated with organic layer, which provides higher anti-corrosion property and a

longer lifespan than that of galvanized steel sheets.

The base metals for prepainted steel sheet consist of cold-rolled, HDG electro-galvanized and hot-dip Alu-zinc

coated. The finish coats of prepainted steel sheets can be classified into groups as follows: polyester, silicon

modified polyesters, polyvinylidene fluoride, high-durability polyester, etc

The production process has evolved from one-coating-and-one-baking to double-coating-and-sigle-baking,double-coating

-and-double-baking and even three-coating-and-three-baking

Standard and Grade :

Pre-paint galvanized steel coil | ||||

ASTM A755M-03 | EN10169:2006 | JISG 3312-2012 | ||

Commercial quality | CS | DX51D+Z | CGCC | |

Structure steel | SS GRADE 230 | S220GD+Z | CGC340 | |

SS GRADE 255 | S250GD+Z | CGC400 | ||

SS GRADE 275 | S280GD+Z | CGC440 | ||

SS GRADE 340 | S320GD+Z | CGC490 | ||

SS GRADE550 | S350GD+Z | CGC570 | ||

S550GD+Z | ||||

Application :

Outdoor | Roof, roof structure, surface sheet of balcony, frame of window, door of garage, rolled shutter door, booth, Persian blinds, cabana, etc |

Indoor | Door, isolater, frame of door, light steel structure of house, home electronic appliances, ect. |

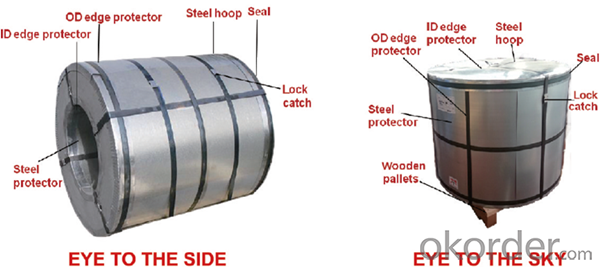

Packing:

Packaging Detail | The packing of coil consists of anti-damp paper ,PVC film ,hardboard paper , steel box , strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye of the side) or wooden pallets(eye of the sky) |

Delivery Time | within 30 days of receipt of LC original or prepayment |

FAQ:

1. What’s the application of this product?

Roof, roof structure, surface sheet of balcony, frame of window, etc.

2. What’s the brand of the paint?

We use the best brand of all of the word—AKZO.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link

from raw material to final product we have strict quality test;We resolutely put an end to

unqualified products flowing into the market. At the same time, we will provide necessary

follow-up service assurance.

4. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange

the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but

the shipment will depend on the vessel situation

- Q: How are steel coils used in the production of steel rings?

- Steel coils are used in the production of steel rings as the primary raw material. The coils are unrolled and cut into smaller sections, which are then shaped and welded together to form the circular shape of the steel rings.

- Q: What is the typical lead time for ordering steel coils?

- The typical lead time for ordering steel coils can vary depending on factors such as supplier availability, production capacity, and shipping logistics. However, it is common for lead times to range from a few weeks to a few months. It is important to communicate with the supplier directly to get an accurate estimate for the specific order.

- Q: I felt that my nylon strings don't sound as good as steel ones. Is it okay that I replace them with steel ones, even if my guitar is classical? Thanks.

- Don't. okorder /

- Q: How are steel coils used in the manufacturing of automotive parts?

- Steel coils are used in the manufacturing of automotive parts as they provide a versatile and cost-effective material for producing various components. These coils are first processed and shaped into specific forms, such as sheets or strips, which are then further worked on to create parts like body panels, chassis, and suspension components. The high strength and durability of steel make it suitable for ensuring the structural integrity and safety of automobiles, while its malleability allows for easy forming and welding processes.

- Q: What are steel coils used for?

- Steel coils are used in a wide range of industries and applications, including manufacturing, construction, automotive, and appliances. They are commonly used in the production of various metal products such as pipes, tubes, sheets, and wires. Steel coils provide strength, durability, and versatility, making them essential in many industrial processes.

- Q: I want to save water $$, so I want to use frozen steel to cool my coke. possible or no?

- can't freeze it but ya can make it very cold

- Q: so i just bought a stainless steel bracelet.......and recently found out that stainless steel isnt actually stainless..........will turpentine ruin it

- real s/steel is nickel and chrome, however manufacturers of kitchenware, e.g s/teel cutlery use the cheaper version of nickel chrome and iron, that is why some s/steel products rust, so if you want to test any products carry asmall magnet and test the article

- Q: What are the common coil slitting methods?

- The common coil slitting methods include rotary shear slitting, loop slitting, and oscillating slitting.

- Q: Can steel coils be stretched?

- Yes, steel coils can be stretched.

- Q: Can steel coils be coated with barcodes?

- Yes, steel coils can be coated with barcodes. Barcodes can be printed or attached onto the surface of steel coils, allowing for easy identification, tracking, and inventory management.

Send your message to us

Ral 5016 color coated steel coil wholesale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 24234 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords