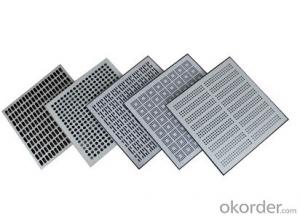

Raised Floor with PVC finish(Steel Panel)

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4000 g/m²

- Supply Capability:

- 50000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Raised Floor with PVC finish(Steel Panel)

Model: HY600

Dimension: 600×600×35(mm)

TYPE | Concentrated Load | Impact Load | Ultimated Load | Uniform Load | Rolling Load | |||

LB | N | KG | N | N | N/㎡ | 10passes | 10000passes | |

HY600-Q | ≥800 | 3550 | 363 | 670 | ≥9400 | ≥14680 | 3560 | 2670 |

HY600-B | ≥1000 | 4450 | 453 | 670 | ≥11970 | ≥16900 | 4450 | 3560 |

HY600-Z | ≥1250 | 5550 | 567 | 670 | ≥14360 | ≥22240 | 5560 | 4450 |

HY600-CZ | ≥1500 | 6660 | 680 | 780 | ≥17950 | ≥26690 | 6670 | 5560 |

Panel,Pedestal and Stringer

Installed Example

PVC Colour Card

601B常用颜色 | 602B | 603B |

604B | 605B |

606B |

|

608B |

609B |

6011B |

6012B |

HF3032B |

PVC conductive vinyl tile is used both for raised floors and other flooring. This product has a permanent anti-static function because of the conductive static network formed at the interface of plastic particles. Its appearance looks like the pattern of marble for a decorative appeal.

This flooring is widely used in program machine rooms, computer rooms, power adjustment houses, purification workshops, and in the telecom, electronics, micro-electronic and medicine industries.

Features:

1) Surface system electric resistance: 1 x 105 - 1 x 108Ω

2) Static electricity decay period: (±500 - ±5,000V)≥2S

3) Amount of wear: ≤0.020g/cm⊃2

4) Combustion property: FV-0 < 10S

5) Starting voltage: V < 100V

- Q: Anti-static PVC board where the use of, please give details of Thank you very much! The The Questions added: or what type of business with anti-static board, the best example Thank you ~ ~ more

- Generally used for the production of anti-static floor, electronics and semiconductor industry used a lot, is the most cost-effective anti-static floor materials....

- Q: What is anti-static floor? Where do I need to install anti-static floor?

- Electrostatic floor are generally power distribution room / weak room / with the fire control room only use

- Q: Why the same is the polyester fiber clothes some static serious some will not

- The disadvantage of polyester fiber is easy to adsorb dust, resulting in static electricity. Wearing polyester fabric fabric is easy to contaminate the dust, not only cause unsightly, the most annoying is the static electricity, not only feel tingling, and if the pants will be because of the electrostatic relationship close to the skin, completely lost Clothing pants type, very unsightly. In order to avoid the defects of polyester fiber, some clothing brands in the fabric of the fabric by adding spandex, cotton and other materials can greatly reduce the generation of static electricity, which appeared with the polyester fiber clothes some static serious some will not be the case The

- Q: Anti-static floor anti-static tiles What is the difference?

- The use of different materials, the use of methods and the role is very different. In general, the anti-static epoxy is better, it combines the smooth wall of the pile of scaffolding lack of painting, conductive, beautiful, seamless, wear and other advantages!

- Q: Anti-static floor material classification

- Anti-static floor - 3, all-steel anti-static floor 2, clean room all-steel anti-static floor 3, protective anti-static floor 4, ceramic surface anti-static floor - metal composite activities floor 5, Anti-static ventilation board anti-static floor - material Fu storage of the emperor Gao Gao Dian Dian Thorough chicken classification aluminum alloy 1, aluminum alloy anti-static ventilation plate 2, aluminum grid plate 3, aluminum alloy blind board anti-static floor - Composite 1, reinforced composite anti-static floor 2, anti-static ceramic steel composite activities floor anti-static floor - material classification calcium sulfate 1, calcium sulfate anti-static floor - three anti-static floor anti-static floor - material classification pvc1, Type permanent pvc anti-static floor 2, permanent PVC anti-static floor anti-static floor - material classification OA network floor 1, all steel 0A network floor

- Q: Composite anti-static floor with an empty one square meter how much money

- Now in the use of such anti-static floor is very small, the price is also expensive and also divided into different types of law for fear of forging ding kicking fist and quality, the highest to more than a thousand, the most expensive to three Hundreds of bars

- Q: Anti-static floor hdg.600.35.q.d what is the meaning

- Specifications: 600 * 600 * 35mm Service life: 10 years Surface resistance: 10 7DD10 9Ω impact resistance open Kouzhuang Kenjiqian Bang Bao Bo strength: 1000 kg g Material: steel filled with cement Wear resistance: high thickness: 30,35 ,,, mmmm

- Q: Network room anti-static floor, how to do grounding

- Pumping 5, '6 points to pick up the room in the bronze medal on the line!

- Q: Anti-static floor with what foot line

- It is best to lay the anti-static static storage of the wing fat Yan Chou Chou Chou Chuan Chuan Chuan porcelain texture of the foot line to do a lot of ceramic have to buy the color specifications by the owners Dongpeng crown beads Mona Lisa have to do, you can ask , There are technical parameters of the test report to adopt

- Q: Anti-static floor which are several

- Taste of long white short-fat mixed with water anti-static floor ceramic anti-static floor composite anti-static floor aluminum anti-static flooring network floor is generally divided into the above five categories, detailed classification

Send your message to us

Raised Floor with PVC finish(Steel Panel)

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 4000 g/m²

- Supply Capability:

- 50000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords