Quilted Mill Finish Aluminum Sheet AA3003 H14 for Curtain Wall

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Mill Finish Aluminum Sheet AA3003 H14 for Curtain Wall

EQUIPMENT | Double coating double baking; |

CAPACITY | 5000Mt/week |

SIZE | Thickness 0.18mm—2mm, width 40mm—1250mm |

PAINT THICKNESS | Top:18--25um, back:5-7um |

COIL WGT | 3Mt - 8Mt |

COIL ID | φ508mm,φ610mm |

SURFACE PAINT | EP, PE, HDP, SMP, PVDF |

COLOR SERIES | RAL color number series |

2. Application of Mill Finish Aluminum Sheet AA3003 H14 for Curtain Wall

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Mill Finish Aluminum Sheet AA3003 H14 for Curtain Wall

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

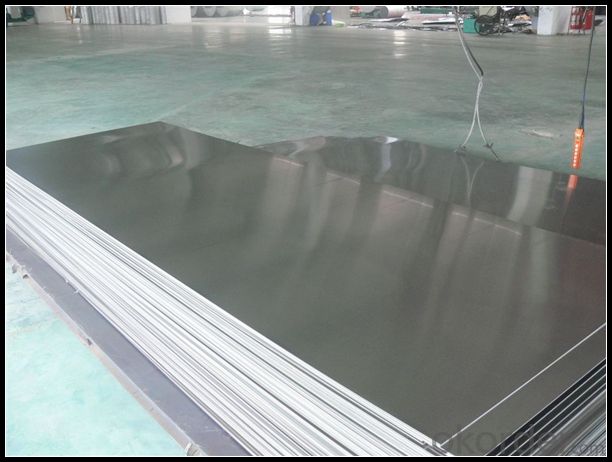

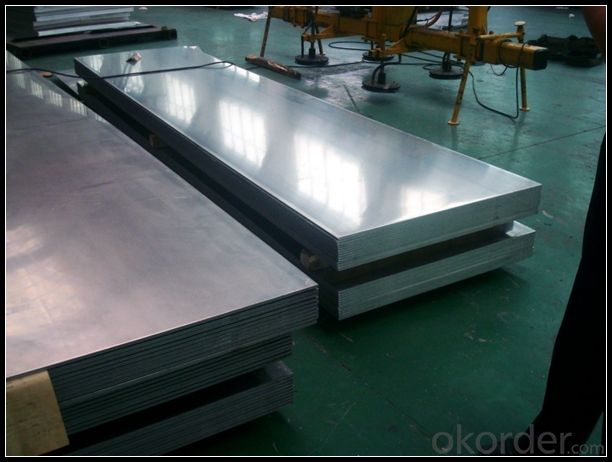

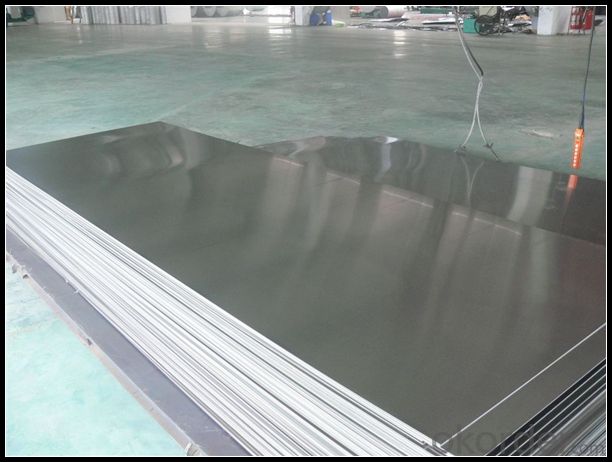

5. Image of Mill Finish Aluminum Sheet AA3003 H14 for Curtain Wall

6. Package and shipping of Mill Finish Aluminum Sheet AA3003 H14 for Curtain Wall

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Can aluminum sheets be used for bus bodies?

- Yes, aluminum sheets can be used for bus bodies. Aluminum is a lightweight and durable material that is commonly used in the construction of bus bodies. Its high strength-to-weight ratio makes it an ideal choice for bus manufacturers, as it allows for improved fuel efficiency and increased payload capacity. Additionally, aluminum is highly resistant to corrosion, which is beneficial for vehicles that are constantly exposed to various weather conditions. Moreover, aluminum can be easily formed and fabricated, allowing for the creation of complex shapes and designs. Overall, aluminum sheets are a popular choice for bus bodies due to their strength, lightness, corrosion resistance, and versatility.

- Q: What are the weight limitations for aluminum sheets in different applications?

- The weight limitations for aluminum sheets vary depending on the specific application. Factors such as the thickness, alloy, and intended usage play a significant role in determining the maximum weight that aluminum sheets can support. It is essential to consult the manufacturer's specifications or engineering professionals for the precise weight limitations in different applications.

- Q: Are aluminum sheets resistant to UV radiation?

- Generally, aluminum sheets are resistant to UV radiation. Aluminum is well-known for its exceptional resistance to corrosion, which also applies to its resistance to UV radiation. The naturally formed oxide layer on the surface of aluminum acts as a shield, safeguarding it against the harmful effects of UV rays. This protective layer ensures that the aluminum does not deteriorate or fade when exposed to sunlight or other UV radiation sources. Nevertheless, it is worth noting that prolonged exposure to intense UV radiation may eventually cause some degradation or discoloration of the aluminum surface. Hence, while aluminum sheets are highly resistant to UV radiation, it is advisable to provide additional protection, such as coatings or paint, for applications that involve extended exposure to harsh UV environments.

- Q: What are the semi hard ones? What are the alloys? What are the anti rust ones, such as 3003505210606061, 7075?

- 3003: board. Strip foil. Tensile plate, tube. Extrusion tube. Type. Rod. Rod. Cold bar, cold wire, rivet wire, forging, foil, heat sink material mainly used for processing requires good molding property, high corrosion resistance, good weldability and spare parts not only have these requirements, or performance need than the workpiece of 1*** alloy with high strength, such as transportation of liquid tank and tank, pressure tank, storage device, heat exchanger, chemical equipment, aircraft fuel tank, oil pipe, reflective panels, kitchen equipment, cylinder washing machine, rivet, welding wire.3003 aluminum alloy sheet, plate, tube drawing. The extruded tube housing partition, cap, pipe3004 plate, plate, pipe extrusion tube for tensile. As long as the whole aluminum cans cans, for more than 3003 alloy parts, chemical products production and storage device, sheet processing, building baffle, cable conduit, sewer, various lighting components.3004 aluminum alloy sheet, plate mainly used for housing partition, baffle, sewer, the roof of industrial plant5052 plate, plate, sheet, foil, drawing tube, cold processing bar, cold wire, rivet wire, this alloy has good shaping property, high corrosion resistance, weldability and fatigue strength, medium static strength, used in the manufacture of aircraft fuel tank, tubing, and vehicles, sheet metal parts, ship the instrument, street lamp and rivet wire and so on.

- Q: What does aluminum plate "3003-H24" mean?

- 3003 is aluminium manganese alloy aluminum plate (Al--Mn), which is mainly composed of manganese.H24: continuous casting, continuous rolling, Zhang Liqiang and partial toughening.Is the aluminum plate with a thickness of more than 0.2mm to 500mm, 200mm width, length less than 16m aluminum material called aluminum plate or aluminum sheet, aluminum is below 0.2mm, 200mm within the width of the row material or bar (of course, with the progress of the large equipment, the width can be 600mm row material also more). Aluminum sheet refers to the rectangular plate made of aluminium ingot rolled and divided into pure aluminum plate, alloy aluminum plate, thin aluminum plate, middle thick aluminum plate and pattern aluminum plate.Aluminium alloy is added in the process of aluminum alloy elements (main alloying elements copper, silicon, magnesium, zinc, manganese, minor alloying elements such as nickel, iron, chromium, titanium, lithium, etc.) in order to improve the mechanical properties of aluminum and chemical index. Alloy aluminum sheet has some special properties of pure aluminum plate, and is widely used in special environment, such as ship, refrigerator, mould, aerospace equipment, etc..

- Q: what family does aluminum belong to?its NOT the boron or aluminum family.i know its group 13. i need the family name.please help

- Aluminum is an orphan metal- (orphans appear in groups 3, 4, and 5 of the periodic table). They are called orphans simply because none belongs to a clearly defined family (like alkaline earth, transition metals, halogens, etc). Sometimes aluminum and the three elements below it in Group 3—gallium, indium, and thallium—are lumped together as the aluminum family, but that's not a clearly recognized family.

- Q: Can aluminum sheets be bent or formed?

- Yes, aluminum sheets can be bent or formed due to their malleability and ductility.

- Q: Is it possible to use aluminum sheets for creating personalized designs or artwork?

- <p>Yes, you can use aluminum sheets to create custom designs. Aluminum is a versatile material that can be cut, shaped, and bent to create various designs. It is lightweight, durable, and resistant to corrosion, making it suitable for both indoor and outdoor applications. You can use techniques such as laser cutting, engraving, or bending to personalize aluminum sheets for your specific needs. Additionally, aluminum can be anodized or painted to achieve different colors and finishes, further enhancing the customization options.</p>

- Q: This question asks for a method to measure the thickness of an aluminum sheet.

- <p>To determine the thickness of an aluminum sheet, you can use a micrometer or a caliper, which are precise measuring tools. Place the sheet on a flat surface and measure from one side to the other at multiple points to account for any inconsistencies. Alternatively, you can use an ultrasonic thickness gauge, which is especially useful for non-contact measurements. For a quick estimate, a simple ruler can give you a rough idea, but for high precision, specialized tools are necessary. Always ensure the measuring device is calibrated and used correctly to get accurate results.</p>

- Q: I saw some pretty horrific pictures today of bow shooters with their hands impale by pieces of a carbon arrow that broke after being shot. I'm about to get into the archery sport, and I just want to know before I buy my arrows, will it be safer to buy aluminum shaft arrows instead of carbon? People said aluminum ones aren't as strong, but right now I'm more concern with the safety factor. Yes, I do know that I'm suppose to always check carbon arrows for cracks before I shoot them, but we're all human and sometimes people will forget and make mistakes. I just don't want my hand embedded with carbon shrapnel. So should I get carbon or aluminum? Maybe the new full metal jacket ones will be a good compromise?As a side note, my first bow will be a recurve somewhere around the 30-35 lb draw range. Does the power of the bow affect the chances of an arrow breakage?

- Sounds like someone was using a traditional, and overdrew and had the carbon arrow come off the rest just as they were releasing it... Thats the 1 and only way i can think of a bow shooter to get bits of a carbon arrow in their hand...That and using a high poundage bow and a low poundage spine carboned arrow

Send your message to us

Quilted Mill Finish Aluminum Sheet AA3003 H14 for Curtain Wall

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords