Sound Insulation Panel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 150 Square Meters m²

- Supply Capability:

- 10000 Square Meters per Week m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

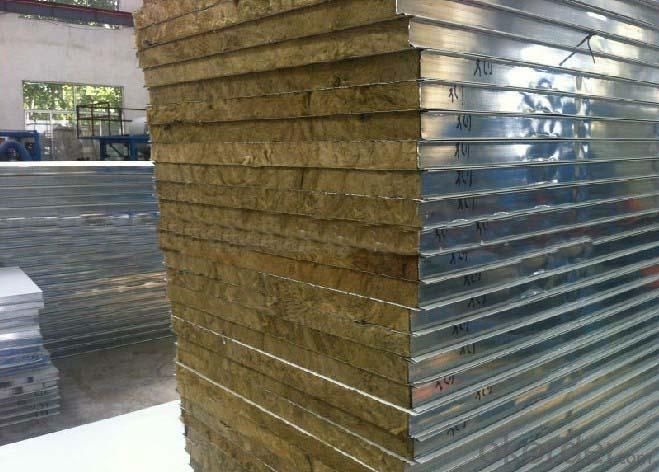

sound insulation panel

Thickness of steel sheet: from 0.2mm to 1.0 mm

Shorten your construction time;

cheap and convenient

sound insulation panel

Characteristic:

1) Core material thickness can be 50/75/100/150/200mm

2) Saving construction time and costs

3) Easy to install and dismantle

4) Economical and Practical

5) Width : 950mm

6) Length: produce as customer's requests

7) core materials : polystyrene , polyurethane and rock wool

Application:

The color steel sandwich plate is mainly suitable for temperature keeping ,heat& sound insulation, water-proof and fire-resistant functions as well as light and decorative application.Such as workshope,temporary office,gymnasia,villa, mobile building, guard booth ,

Prefabricated house, Container house, light steel structure ,cold storages and Clean room engineering etc.

- Q: Rock wool sandwich board Yanmian generally what brand, quality Zeyang?

- We are all with a small factory rock wool, we do not know the manufacturers, but this thing is too much pollution

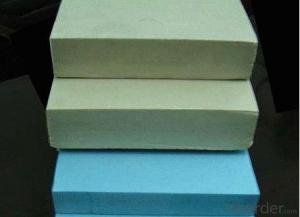

- Q: Extruded polystyrene board and color steel sandwich board which is better

- See what you can do with the use of external wall insulation, then you can use the extruded board for the activities of temporary housing roof wall panel that color steel sandwich panels

- Q: What are the benefits of color steel?

- Color plate is made of polystyrene foam sandwich panel surface, closed-hole self-extinguishing polystyrene foam to do the core material, through the automatic continuous molding machine will be colored steel plate with high-strength adhesive after bonding A new type of composite building materials, mainly for public buildings, industrial plants, roofs, walls and clean rooms and the combination of cold storage, building joints, kiosks, etc., it has a heat, waterproof once completed, construction speed, durable, Nice and so on

- Q: Bubble (EPS) color steel sandwich panels how to wear thread

- EPS sheet can not use the dark cable way, you must use PVC flame retardant pipe cable, need to use the hole at the hole, out to look good.

- Q: Sandwich board is 50,75,100,150, color steel thickness, casually one can.

- 50 thick: 45 ~ 75 yuan 75 thick: 53 ~ 87 yuan 100 thick: 62 ~ 95. Sandwich panel thickness is not limited. I am also about this. Because you are not very clear.

- Q: What is the difference between the board and the core board? Usually where the place with sandwich panels where the use of laminates, such as the use of the shoe is the board, wardrobe with a sandwich panel? So what is the difference between the two

- Daxing board is made of two pieces of veneer stagnant stitching wood. Daxin board price is cheaper than the core board, the vertical (to the core material to distinguish) bending strength is poor, but the lateral bending pressure The strength is more ... but the general is best not to choose! 2. Plywood, also known as plywood, some people called the carefully board. Three or more layers by 1mm thick veneer sheet made of hot pressing. Plywood is generally divided into 3mm, 5mm , 9mm, 12mm, ... Plywood Optional plywood is made of multi-layer veneer staggered arrangement of the sheet. The outermost front panel is called the panel, the reverse is called the back plate. Core board.

- Q: The use of foam sandwich panels erection of the temporary board of the building components of the combustion than the A-level, to rectification, how to engage in ah

- Rectification is to ask them to eat, plug the red envelope, it is necessary to use A-class fire estimates can only be used instead of rock wool, the price is 15 yuan high 1 square meter

- Q: What are the key notes when buying a rock wool sandwich panel?

- 1. Slag content; slag content determines the quality of rock wool. High-quality rock wool is made from basalt or diabase, while poor quality rock wool is mixed with blast furnace slag or other metallurgical slag. In contrast, the slag content is low and the acidity is low Poor, with the temperature changes will greatly accelerate the fiber fracture and powder, thus losing strength and insulation properties. So, will become a building hazard. 2. Fiber average diameter; national standard is ≤ 7μm. The new rock wool fiber-forming process combined with the basalt material itself makes the rock wool fiber slender and flexible, the fiber diameter can be stabilized at 4-7μm; the pendulum method and the multi-dimensional pleating technique make the distribution of the Yanmian fiber evenly and in three dimensions Chaos, greatly improving the density and strength of rock wool. 3. Thermal conductivity; high quality rockwool slag ball content is low, fiber diameter is moderate, the use of pendulum method of production technology, fiber distribution, uniform direction, bulk density uniformity, low thermal conductivity. Poor rock wool is the opposite. Usually slag cotton using sedimentation chamber production process, low thermal conductivity

- Q: What is the level of fire protection for the production of polyurethane sandwich panels?

- Class C plant.

- Q: How do you make a curved shape on a sandwich panel?

- You can open a lot of slots on the board, the depth of the slot than the thin about two millimeters, each slot spacing to stay three millimeters. The whole board to open such a slot, so that you can make a curved

1. Manufacturer Overview

| Location | Shandong,China |

| Year Established | 2003 |

| Annual Output Value | |

| Main Markets | North America South America Southeast Asia Africa Mid East Eastern Asia Western Europe Central America South Asia Domestic Market |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | Qingdao |

| No.of Employees in Trade Department | |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | Design Service Offered |

| Product Price Range | Average |

Send your message to us

Sound Insulation Panel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 150 Square Meters m²

- Supply Capability:

- 10000 Square Meters per Week m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords