Q41(QHK)125 MACHINE VICE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are a specialized company for machine vises , whoseproducts are exported to Europe and America as well as developed countries .Wehave Q12,Q13,Q41,QM,QMN series .All the products have high precision ,and reasonabledesigns and reach the JB/T2329-11 standards .

Weare insisting that the quality is first and reputation is the best. We refocusing on our quality and innovation , We are looking forward to havingopportunities to set up more business relations with customers from all overthe word and establish the long-term cooperation with best products and perfectafter-service.

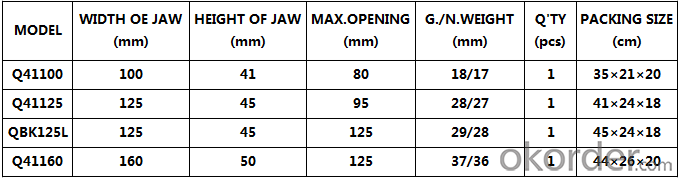

Q41(QHK) SeriesMachine Vice

Performance and character:

1. It adopts the high-quality cast irons.

2. Both parallelismand verticality about the two jaws are 0.025mm/100mm.

3. The vice can beadjusted and locked at random from the horizontal position to the verticalposition (0°-90°)with swiveling base being rotated 360°.

4. It can be widelyused for processing all kinds angels of surface, slots and holes.

- Q: Pneumatic vice and hydraulic vice are good

- The price ranges from a thousand yuan to a thousand yuan。I hope my answer will help you。

- Q: Is there a god who is good at drawing mechanical drawings?

- Bench vice, also called vice, bench vice. A bench vice is a common fixture for holding a piece of work. The equipment is on the workbench, which can be used to clip the workpiece, which is a necessary tool for the fitter workshop. The rotary clamp can rotate to make the workpiece rotate to the appropriate position.

- Q: Push it to the required piece of work, then lock the screw with the inner hexagon wrench to achieve a tight end. What I want to know is the design structure of it, if you have this kind of vice in your hand, you can show me a few pictures, especially the lock structure underneath it. There is a drawing change. If you know what it's called, give it a name,

- This structure used to be used mainly for the precision flat tongs used in grinding machines.

- Q: Is the screw of a vice clamp a silk stick? How do you choose a screw with the same principle? The device requires a general assembly

- The screw on the top of the vice clamp is actually a silk pole. The first thing you don't know is how big a clamping device you want to do. It is recommended that you choose a silk rod that is no less than thirty in diameter (the specific pitch is chosen according to the actual situation). Note: the minimum material of the material is 45 steel. Silk mother chooses tin bronze silk mother.

- Q: How to find a positive two vice

- Then adjust the level of water level (both of which are consistent with the working table) - the magnetic watch seats are drawn on the main shaft

- Q: Will the bench work on the bench vice?

- There is no standard, the bench vice is installed in the corner of the workbench.

- Q: What does Taiwan's vice President stand for

- The eight inches of the bench means the length of the tongs.

- Q: What is mechanical vice material

- Carbon steel, a relatively poor quality, is now the most material on the market, and the price is lower

- Q: Several basic USES of bench vice

- Chinese name: vise English name: bench vice "definition: installed on the bench, with the tool of jaw clamping workpiece Essential tool vise for fitter, and fitter for the name of the source, because the bench most of the work is done on the vise, such as saws, file, chisel, and the components of the assembly and disassembly. Installed on the bench, the width of the tongs is the calibration specification. Common specifications range from 75mm to 300mm. Use of bench vice: the machine is on the workbench, which can be used to clip the workpiece, which is a necessary tool for the fitter workshop

- Q: How do you beat the sink hole of the pincers with two screws, with a drill or a milling cutter

- The drill and the milling cutter can go through the sink, as long as the sink can be drawn out. Drill the hole first, then the sink.

Send your message to us

Q41(QHK)125 MACHINE VICE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches