QM16200 ACCU-LOCK MACHINE VICE WITHOUT SWIVEL BASE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are a specialized company for machine vises , whoseproducts are exported to Europe and America as well as developed countries .Wehave Q12,Q13,Q41,QM,QMN series .All the products have high precision ,and reasonabledesigns and reach the JB/T2329-11 standards .

Weare insisting that the quality is first and reputation is the best. We refocusing on our quality and innovation , We are looking forward to havingopportunities to set up more business relations with customers from all overthe word and establish the long-term cooperation with best products and perfectafter-service.

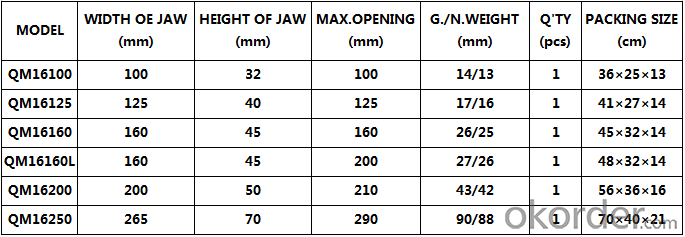

QM Series MachineVice

Performance and character:

1. It is one of main attachmentsfor milling、drillingmachine ,it is particularly suitable for the finishing of precision parts.

2. The accuracy of vice (parallelismand squareness) is 0.025mm/100mm.

3. The special segment in themovable jaw forces the vertical pressure downward when the horizontal pressureworks, so that this jaw does not lift the work piece.

4. Four positions allow extracapacity to change opening of jaw.

- Q: How to calibrate the CNC milling machine tongs

- To find a better table or magnetic platform with a horizontal plane, use the calibration table to verify that its horizontal error is small. The existing top of the workpiece is placed on the table or on the magnetic platform, and the verticality of the semicircle and the "bottom" is measured with the school table, and the right Angle of the processing is confirmed.

- Q: How do you mill a step up the miller's vice

- If necessary for holding the piece, remove the clamp and replace it with homemade tongs. Don't lose this good part for some reason.

- Q: What do you mean by rotating mechanical vice

- It is a kind of tool that can rotate mechanical devices.

- Q: What is the use of a vice

- Machine vise has a very wide range of USES, common in processing various parts on machine tool clamping. Such as milling machine, up &will waste on the bed, drilling machine parts is commonly used when to clamp fixed parts processed with vice

- Q: How does the UG set the motion simulation of the bench vice

- Pedestal - fixed link Screw -rotary pay Sliding block Rotating payment + sliding - screw pay

- Q: Several basic USES of bench vice

- Essential tool vise for fitter, and fitter for the name of the source, because the bench most of the work is done on the vise, such as saws, file, the chisel, and the components of the assembly and disassembly.

- Q: The large aluminum plate will not deform 250 * 240 * 16

- Yes, the thickness of 16 is not enough, especially the ordinary vice clamp is hard to control

- Q: Who has a parts drawing and assembly diagram for a vice?

- You can find the relevant information on baidu machine, hope you can help

- Q: What is the width of the tongs? Is it the same thing?

- I check "QBT 1558.2-1992 vice bench vice", The width of the vice jaw is the same as the opening. If you want "QBT 1558.2-1992 vice bench vice" electronic press, give email address.

- Q: How do you beat the sink hole of the pincers with two screws, with a drill or a milling cutter

- There are two types of options for processing a processing center: One. Drill holes, drill holes, reamer drills, reamer, etc. 2. Milling hole, the use of two or 90 ° right-angle milling cutter milling machining cutter: For small holes such as 30mm in diameter, you can use a double-edged milling cutter for processing. A small blind hole can also be used for a two-blade milling cutter. Small waist type hole, the most reasonable with two-edge milling cutter, drill down to depth first, and then cross the knife. (the large waist type hole will be drilled with a bit and then used to cut the hole to the waist.) Using the 90 ° Angle cutter will have to use milling spiral interpolation, the premise is tool must be smaller than the pore size, all kinds of macroporous, sink holes, waist type hole, ellipse, etc this method processing; There are many other special ways to process the outside of a CNC machine. For example, the perforation of the barrel of the gun, the forming of the shaft of the barrel in the barrel of the barrel, the forming hole, the grinding hole, the rolling hole, the honing hole, Micro-hole processing of the laser threshold, a type of non-circular hole machining based on electromagnetic drive, etc.

Send your message to us

QM16200 ACCU-LOCK MACHINE VICE WITHOUT SWIVEL BASE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches