Q12(QH)80 MACHINE VICE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are a specialized company for machine vises , whoseproducts are exported to Europe and America as well as developed countries .Wehave Q12,Q13,Q41,QM,QMN series .All the products have high precision ,and reasonabledesigns and reach the JB/T2329-11 standards .

Weare insisting that the quality is first and reputation is the best. We refocusing on our quality and innovation , We are looking forward to havingopportunities to set up more business relations with customers from all overthe word and establish the long-term cooperation with best products and perfectafter-service.

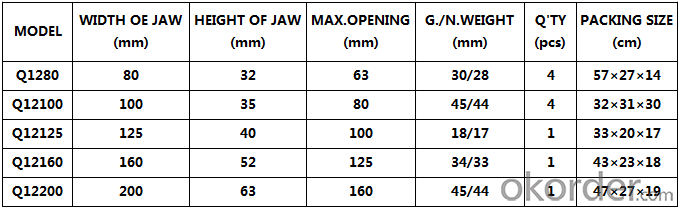

Q12(QH)series Machine Vice:

Performanceand character:

1. It adopts the high-quality castirons.

2. Both parallelism andverticality about the two jaws are 0.025mm/100mm.

3. It is widely used for themilling machine and the drilling machine to process some surface ,slots andholes.

- Q: What's the difference between a vice and a vice

- Use of flat tongs Pincers are also known as vice, a common fixture that is used to install small workpieces. It is a random attachment for milling machines and drilling machines. It is fixed to the machine tool workbench, and it is used for cutting and processing of the workpiece. The working principle of flat tongs Use the wrench to move the screw and move the clamps through the screw nut, forming the tightening and loosening of the workpiece. The size of the sandwiched piece shall not exceed 70 mm.

- Q: What are the characteristics and advantages of precision vice?

- Of course, there are also oil pressure tongs, but they are tighter and stronger, eliminating the wear of the thread. Pneumatic electric tongs are also available, which is to make use of more convenient, lower labor intensity and mechanical and electrical integration.

- Q: What do you mean by rotating mechanical vice

- This is the bench vice that we use on a regular machine It is one of the necessary tools of the fitter to rotate the workpiece with the silk pole

- Q: How do milling machine tongs correct

- The left and right side of the bed allows the probe to be moved to the other end of the machine with the tongs, and the measuring reading is different. If different, the machine with soft head hammer and light hammer side of the machine vice side, correct and correct, the machine will be clamped tightly. In general, because of the precision of the vice structure of the machine, it is not necessary to check the parallel degree of the bottom surface of the tongs of the xoxen milling machine

- Q: What is the difference between the heavy duty and the light, how to choose the size of the tongs, usually 8 inches or 10 inches

- Also, don't know what to buy? There were a dozen, dozens, and a hundred, and more than two hundred, five hundred and six hundred, and I didn't know how much to buy. I'm a diy knife, black hey!

- Q: Use of bench vice (simple point)

- The vice clamp on the table must be firm, two clamped screws must be tightened.

- Q: Describe the method of attaching the piece of work to the machining center with vice clamp.

- So that's the same thing as the X-axis. And then fix it,I hope my answer will help you

- Q: What is the use of a vice

- Our company is using the vice of the machine of the dongguan company machine, the quality is very good.

- Q: What is mechanical vice material

- Carbon steel, a relatively poor quality, is now the most material on the market, and the price is lower

- Q: What is the use of the screw on the pincers of the flat slot with two orifices

- Bolted to the chassis of the machine tool,I hope my answer will help you

Send your message to us

Q12(QH)80 MACHINE VICE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords