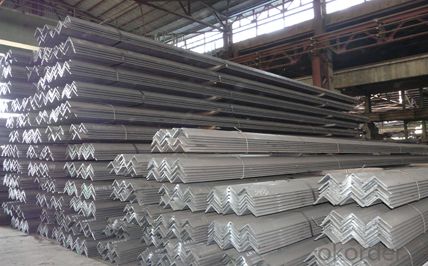

Q345 Material High Quality Angle Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Angle Steel great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

According to the needs of different structures, Angle can compose to different force support component, and also can be the connections between components. It is widely used in various building structures and engineering structures such as roof beams, bridges, transmission towers, hoisting machinery and transport machinery, ships, industrial furnaces, reaction tower, container frame and warehouse etc.

Product Advantages:

OKorder's Angle Steelare durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

1. Invoicing on theoretical weight or actual weight as customer request

2. Length: 6m, 9m, 12m as following table

3. Sizes

Sizes: 25mm-250mm | ||

a*t | ||

25*2.5-4.0 | 70*6.0-9.0 | 130*9.0-15 |

30*2.5-6.6 | 75*6.0-9.0 | 140*10-14 |

36*3.0-5.0 | 80*5.0-10 | 150*10-20 |

38*2.3-6.0 | 90*7.0-10 | 160*10-16 |

40*3.0-5.0 | 100*6.0-12 | 175*12-15 |

45*4.0-6.0 | 110*8.0-10 | 180*12-18 |

50*4.0-6.0 | 120*6.0-15 | 200*14-25 |

60*4.0-8.0 | 125*8.0-14 | 250*25 |

Note:

1. According to national standard (GB) for our products, if not, supply according to national standards (GB) or agreement.

2. We can not only provide electric furnace +LF+VD and electro-slag re-melting (ESR)steel forging materials, but also forging products of piece, bar, etc.

3. Our company is equipped with roll equipment and can provide our customers with roll billets or finished.

4. Please send us your detailed specifications when inquire. We will reply to you ASAP.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2 What makes stainless steel stainless?

A2 Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q3 Can stainless steel rust?

A3 Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Images:

- Q: How do you prevent warping of steel angles during fabrication?

- To prevent warping of steel angles during fabrication, several measures can be taken. Firstly, it is essential to ensure proper storage and handling of the angles to avoid any bending or twisting. During welding or heating processes, it is crucial to control the temperature and heat distribution evenly to prevent localized expansion or contraction that may lead to warping. Additionally, using proper clamping or fixturing techniques can help maintain the desired shape and prevent warping. Lastly, post-fabrication processes like stress relieving or annealing can be employed to release any residual stresses in the angles and minimize the risk of warping.

- Q: What are the common industry standards for steel angles?

- The common industry standards for steel angles include various dimensions such as the length, width, and thickness of the angles, as well as tolerances, surface finishes, and mechanical properties. These standards are set by organizations such as the American Society for Testing and Materials (ASTM) and the International Organization for Standardization (ISO) to ensure consistency and quality in the production and use of steel angles across different industries.

- Q: Can steel angles be used as supports for overhead doors or garage doors?

- Indeed, overhead doors or garage doors can rely on steel angles as their supports. Due to their impressive strength and durability, steel angles are frequently employed in construction. They offer superb support and stability for hefty doors, making them an ideal selection for overhead or garage doors. By securely fastening the angles to the walls or framework, a sturdy foundation is provided for the doors to hang on and function seamlessly. Moreover, steel angles can be tailored to fit the precise dimensions and weight prerequisites of the doors, guaranteeing adequate support and functionality.

- Q: How do steel angles perform in high-wind regions?

- Steel angles perform well in high-wind regions due to their structural strength and ability to resist wind loads. The angled shape of the steel provides stability and prevents the structure from swaying or being damaged by strong winds. Additionally, steel angles are commonly used in the construction of buildings and structures in high-wind areas, such as hurricane-prone regions, as they offer excellent resistance to wind pressure. The high tensile strength of steel makes it highly resilient to the forces exerted by strong winds, ensuring the stability and integrity of the structure. Moreover, steel angles can be designed and engineered to meet specific wind load requirements, enabling them to withstand extreme weather conditions. Overall, steel angles are a reliable and effective choice for construction in high-wind regions, ensuring the safety and durability of the structures.

- Q: Can steel angles be used in conveyor belt supports?

- Yes, steel angles can be used in conveyor belt supports. Steel angles are commonly used as structural supports in various applications due to their strength and durability. They provide excellent load-bearing capacity and can withstand heavy weights, making them suitable for supporting conveyor belts. The angles can be used to create a sturdy framework or structure that holds the conveyor belt in place and allows it to move smoothly. Additionally, steel angles can be easily fastened or welded together, providing a secure and stable support system for conveyor belts.

- Q: Can steel angles be used as lintels or supports for openings?

- Yes, steel angles can be used as lintels or supports for openings. Steel angles are commonly used in construction as structural elements due to their strength and durability. When used as lintels or supports for openings such as doors and windows, steel angles provide the necessary structural support to bear the load above the opening. They can be installed horizontally above the opening, with one leg of the angle bearing against the wall on either side. The load from the structure above is transferred to the steel angle, which in turn distributes the load to the surrounding walls. Steel angles are a popular choice for lintels and supports due to their high load-bearing capacity and resistance to bending and twisting forces.

- Q: Can steel angles be used for outdoor applications?

- Indeed, outdoor applications can make use of steel angles. Fashioned from a robust and enduring material, steel angles prove themselves apt for a multitude of outdoor endeavors. Frequently employed in construction, infrastructure, and engineering ventures necessitating structural support or reinforcement, steel angles endure inclement weather conditions, including rain, snow, and direct sunlight, without succumbing to decay or weakening. Moreover, steel angles possess the potential to be coated or treated, amplifying their ability to resist corrosion and further augmenting their appropriateness for outdoor applications. On the whole, steel angles present themselves as a dependable and adaptable option for outdoor projects requiring durability, strength, and long-term reliability.

- Q: Are steel angles suitable for supporting heavy machinery?

- Yes, steel angles are suitable for supporting heavy machinery. Steel angles are known for their strength and durability, making them a reliable choice for providing structural support to heavy machinery. They offer excellent load-bearing capabilities and can withstand the weight and stress exerted by heavy machinery, ensuring stability and safety.

- Q: How do steel angles perform in corrosive or acidic environments?

- Steel angles perform well in corrosive or acidic environments due to their inherent resistance to corrosion. The presence of alloying elements, such as chromium and nickel, in stainless steel angles enhances their corrosion resistance, making them suitable for such environments. Additionally, a protective oxide layer forms on their surface, providing further protection against corrosive elements.

- Q: Can steel angles be used in marine or underwater applications?

- Indeed, one can utilize steel angles in marine or underwater settings. Frequently, steel angles find application in the fabrication of diverse marine infrastructures, including vessels, offshore platforms, and subaqueous pipelines. The superior strength and corrosion resistance possessed by steel render it apt for enduring the challenging circumstances of the marine milieu, encompassing contact with saltwater and extreme temperatures. Moreover, the ease with which steel angles can be welded or bolted together to construct a robust and long-lasting framework makes them an optimal selection for marine and underwater purposes.

Send your message to us

Q345 Material High Quality Angle Steel

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords