Hot Rolled Steel Angle Q345

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Hot Rolled Steel Angle Q345

1. Standards: GB,ASTM,BS,AISI,DIN,JIS

2. Length:6m,9m,12m

3. Material:Material: GB Q235B, Q345B or Equivalent; ASTM A36; EN 10025, S235JR, S355JR; JIS G3192, SS400;

SS540.

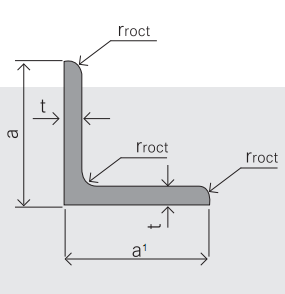

4. Sizes:

Sizes: 25mm-250mm | ||

a*t | ||

25*2.5-4.0 | 70*6.0-9.0 | 130*9.0-15 |

30*2.5-6.6 | 75*6.0-9.0 | 140*10-14 |

36*3.0-5.0 | 80*5.0-10 | 150*10-20 |

38*2.3-6.0 | 90*7.0-10 | 160*10-16 |

40*3.0-5.0 | 100*6.0-12 | 175*12-15 |

45*4.0-6.0 | 110*8.0-10 | 180*12-18 |

50*4.0-6.0 | 120*6.0-15 | 200*14-25 |

60*4.0-8.0 | 125*8.0-14 | 250*25 |

5. Chemical data: %

C | Mn | S | P | Si |

0.14-0.22 | 0.30-0.65 | ≤0.050 | ≤0.045 | ≤0.30 |

Usage & Applications of Equal Angle

Trusses;

Transmission towers;

Telecommunication towers;

Bracing for general structures;

Stiffeners in structural use.

Packaging & Delivery of Hot Rolled Steel Angle Q345

1. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

2. With bundles and load in 20 feet/40 feet container, or by bulk cargo, also we could do as customer's request.

3. Marks:

Color mark: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: There will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

- Q: What are the considerations for selecting the appropriate steel angle finish?

- When selecting the appropriate steel angle finish, there are several considerations to keep in mind. Firstly, the intended use and environment of the steel angle should be considered. If the angle will be exposed to harsh weather conditions or corrosive substances, a finish with high resistance to corrosion, such as galvanized or stainless steel, would be suitable. Additionally, the aesthetic requirements of the project should be taken into account. Different finishes, such as powder coating or painted finishes, can provide a range of colors and textures to enhance the appearance of the steel angle. Finally, the budget and cost-effectiveness of the finish should be considered, as some finishes may be more expensive than others. Overall, it is important to select a steel angle finish that meets both the functional and aesthetic requirements of the project while being compatible with the intended environment.

- Q: Can steel angles be painted or coated after installation?

- Yes, steel angles can be painted or coated after installation. Painting or coating steel angles after installation can provide additional protection against corrosion and enhance their aesthetic appeal. Prior to painting or coating, it is important to clean and prepare the surface by removing any dirt, rust, or contaminants. This can be done through techniques such as sandblasting, wire brushing, or using chemical cleaners. Once the surface is clean and dry, a suitable primer can be applied to promote adhesion and prevent corrosion. After the primer has dried, a final coat of paint or coating can be applied using a brush, roller, or spray. It is essential to choose a paint or coating that is specifically designed for steel and offers the desired level of protection and durability.

- Q: Can steel angles be used in the construction of conveyor systems?

- Yes, steel angles can be used in the construction of conveyor systems. Steel angles are commonly used as structural support in conveyor systems to provide stability and strength to the framework. They can be easily welded or bolted together to create the desired configuration for the conveyor system, making them a versatile and reliable choice in construction.

- Q: What are the different types of steel angles used in manufacturing industries?

- In manufacturing industries, there is a wide variety of steel angles utilized for different purposes. These angles possess unique characteristics that make them suitable for specific applications. 1. Unequal Leg Angles, also known as L-shaped angles, feature one longer leg and one shorter leg. They find common usage in construction and structural engineering due to their versatility. These angles offer exceptional strength and stability, making them ideal for supporting heavy loads and establishing structural connections. 2. Equal Leg Angles, also known as L-shaped angles, have both legs of equal length. They are extensively employed in manufacturing industries for diverse purposes, including bracing, framing, and supporting structures. These angles exhibit good resistance to bending and provide stable connections in various applications. 3. Stainless Steel Angles are crafted from a corrosion-resistant steel alloy, primarily comprising chromium. They possess remarkable durability, resistance to rust, and excellent strength properties. Stainless steel angles find widespread use in industries such as food processing, chemical processing, and marine manufacturing, where corrosion resistance is of utmost importance. 4. Galvanized Steel Angles are coated with a layer of zinc to safeguard them against corrosion and rust. This zinc coating ensures exceptional durability and longevity, rendering galvanized steel angles suitable for outdoor and exposed applications. They are commonly employed in industries like construction, agriculture, and transportation. 5. Rolled Steel Angles are manufactured by rolling a steel plate or sheet into the desired shape. These angles offer an excellent strength-to-weight ratio and can be produced in varied sizes and thicknesses. Rolled steel angles find extensive usage in construction, machinery, and fabrication industries for structural support and framing applications. 6. Slotted Steel Angles possess holes or slots along their length, allowing for flexibility in terms of fastening methods. They are frequently employed in shelving systems, racking, and storage solutions as they allow for easy adjustment and customization. Slotted steel angles offer versatility and convenience in manufacturing industries where quick assembly and reconfiguration are required. In summary, the assortment of steel angles utilized in manufacturing industries provides a range of properties and advantages. The choice of angle depends on the specific application, requirements for strength, corrosion resistance, and other factors that guarantee optimal performance and durability in the given application.

- Q: Can steel angles be used for retaining walls?

- Steel angles are a viable option for retaining walls. In construction, steel angles are commonly employed for a variety of purposes, including supporting structures and constructing retaining walls. They offer stability and strength to the wall, making them suitable for retaining soil or other substances. Steel angles can serve as the primary structural element or be combined with materials like concrete or timber to create a durable and robust retaining wall. The specific factors to consider in the design and engineering process would be the wall's height, load requirements, soil conditions, and local building codes. However, when properly designed and installed, steel angles can prove to be an effective choice for retaining walls.

- Q: Are there any limitations on the angle of inclination for steel angles?

- Yes, there are limitations on the angle of inclination for steel angles. The angle of inclination refers to the angle at which the steel angle is installed or positioned in a structure. The limitations on this angle depend on various factors, including the type and thickness of the steel angle, the load it is expected to bear, and the specific design and engineering requirements of the structure. In general, steel angles can be installed at various angles of inclination, ranging from vertical (90 degrees) to horizontal (0 degrees). However, there are practical limitations that need to be considered. Steel angles are typically designed to bear loads in a specific direction, and deviating too far from the intended angle of inclination can impact their structural integrity and load-bearing capacity. Furthermore, the installation angle of steel angles may be limited by the connection methods used. Welding, bolting, or other fastening techniques may have specific requirements for the angle of inclination to ensure proper connection strength and stability. It is important to consult the relevant building codes, standards, and engineering guidelines to determine the specific limitations on the angle of inclination for steel angles in a particular application. Professional structural engineers can provide the necessary expertise and guidance to ensure that the steel angles are installed within safe and appropriate limits.

- Q: How do you calculate the stability of a steel angle column?

- Determining the stability of a steel angle column involves considering several crucial factors. The first step is to calculate the slenderness ratio of the column, which is the ratio between its effective length and its least radius of gyration. This can be done using the following formula: Slenderness ratio = (Effective length of column) / (Least radius of gyration) To find the least radius of gyration, the dimensions of the angle section must be used. For a steel angle, an approximation can be made by taking the average of the two legs of the angle section and dividing it by the square root of 3. Once the slenderness ratio is determined, it is necessary to assess whether the column is classified as long or short. If the slenderness ratio is below the critical value, typically around 50 for an angle column, it is considered short, and its stability primarily depends on its strength. In such cases, the column can be designed based on its ability to resist axial compression and flexural buckling. However, if the slenderness ratio surpasses the critical value, the column is classified as long, and its stability depends on its capacity to resist lateral-torsional buckling. In these instances, additional calculations and considerations are required to ensure the column remains stable. For long angle columns, the critical load at which lateral-torsional buckling may occur can be determined using various formulas and methods, such as the Euler formula, the Perry-Robertson formula, or finite element analysis. These calculations take into account various parameters, including the moment of inertia, modulus of elasticity, and length of the column. It is important to acknowledge that stability calculations for steel angle columns can be intricate and necessitate expertise in structural engineering. It is strongly advised to consult with a qualified professional or refer to relevant design codes and standards, such as the American Institute of Steel Construction (AISC) Manual, for accurate and reliable calculations.

- Q: What are the different load-carrying capacities for steel angles?

- The load-carrying capacities for steel angles vary depending on factors such as the size, shape, and material of the angle, as well as the specific application and installation method. It is recommended to consult engineering resources, industry standards, or a structural engineer for accurate load-carrying capacity information.

- Q: How do steel angles perform under high temperatures?

- Steel angles perform well under high temperatures due to their high melting point and excellent heat resistance. Steel is a widely used material in construction and engineering, known for its structural strength and durability. When exposed to high temperatures, steel angles retain their structural integrity and do not deform or weaken easily. This is because steel has a high melting point, typically around 1370 to 1530 degrees Celsius (2500 to 2800 degrees Fahrenheit), which allows it to withstand extreme heat without significant damage. Additionally, steel has excellent heat resistance, meaning it can dissipate heat efficiently and maintain its stability under high thermal loads. This makes steel angles suitable for applications where elevated temperatures are present, such as in industrial furnaces, power plants, or high-temperature environments. However, it is important to note that the specific performance of steel angles under high temperatures may vary depending on the grade and composition of the steel, as well as the duration and intensity of the heat exposure.

- Q: What are the different types of steel angles used in machinery?

- There are several types of steel angles commonly used in machinery, including equal angles, unequal angles, L-shaped angles, and T-shaped angles. These angles are used to provide structural support, reinforce joints, and facilitate the assembly of various components in machinery.

Send your message to us

Hot Rolled Steel Angle Q345

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords