Q235 Carbon Steel Sheet Prices Hot Rolled Mild Steel Plate Prices

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Q235 Carbon Steel Sheet Prices Hot Rolled Mild Steel Plate Prices

Detailed Information of Q235 Carbon Steel Sheet Prices Hot Rolled Mild Steel Plate Prices

| C | Si | P | S | yield Strength MAp | Tensile strength MAp | Elongation % | ||

| A36 | 0.24 | 0.4 | 0.045 | 0.03 | 250 | 400-520 | 26 | |

| C | Si | Mn | P | S | Cu | |||

| A283 | ≤0.27 | 0.15-0.4 | ≤0.9 | ≤0.035 | ≤0.04 | ≥0.2 | ||

| Thickness: | 6mm, 8mm, 12mm, 16mm, 20mm, 25mm, 30mm, 50mm, 80mm, 100mm, 150mm, 200mm | |||||||

| Width: | 1500mm, 1800mm, 2000mm, 2200mm, 2500mm | |||||||

| Length: | 6000mm, 8000m, can cut to width and length | |||||||

| Packing Details; | according to customer‘s require or export’s standard | |||||||

| Delivery time; | 7 days for stock sizes, 20-25 days for new production sizes | |||||||

| Port: | Tianjin China | |||||||

Related Products Overviews of Q235 Carbon Steel Sheet Prices Hot Rolled Mild Steel Plate Prices

Product Name | Typical Grades | Diameter(mm) | Standard Adopted |

Carbon Steel | 20 (1020/S20C/C22) |

Ø16-Ø300 |

GB/SAE/ JIS/DIN |

40 (1040/S40C/C40) | |||

45 (1045/S45C/C45) | |||

Bearing Steel | GCr9 (51100/SUJ1) |

Ø12-Ø250 | |

GCr15 (52100/SUJ2/100Gr6) | |||

GCr9SiMn (A485-Gr.1/SUJ3) | |||

Cr-Mo Steel | 20Cr (5120/SCr420H/20Cr4) |

Ø12-Ø250 | |

40Cr (5140/SCr440/41Cr4) | |||

42CrMo(4140/SCM440/42CrMo4) | |||

Gear Steel | 20CrNiMo |

Ø16-Ø600 | |

20CrMn(5115/SMnC420/20MnCr5) | |||

20CrNiMo(8620/SNCM220/20CrMiMo2) |

Related Products Application of Q235 Carbon Steel Sheet Prices Hot Rolled Mild Steel Plate Prices

Carbon Steel | l Mold bottom l Plastic mold l Construction machinery parts l Automobile parts l Security grills l Screens l Construction |

Bearing Steel | l Aerospace l Navigation l Nuclear energy l Chemical industry l Electronic information l Petrochemical l Instrument and meter l Transportation |

Cr-Mo Steel | l Mechanism & Fasteners gear l Stressed components for vehicles l Engines and machines l Parts of larger cross-section |

Gear Steel | l All kinds of gears l Statically and dynamically stressed component for vehicles l Engines and machine l Larger cross-section parts l Crankshafts |

Company Introduction of Q235 Carbon Steel Sheet Prices Hot Rolled Mild Steel Plate Prices

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

After-sale service | l CNBM provides the services and support you need for every step of our cooperation. We’re the business partners you can trust; you can relax and get on with doing business. l For any problem, please kindly contact us at any your convenient time, we’ll reply you in our first priority within 24 hours

|

Advantages

| l Industry experience over 20 years. l Shipment of goods -More than 70 countries worldwide. l The most convenient transport and prompt delivery. l Competitive price with best service. l High technical production line with top quality products. l High reputation based on best quality products.

|

Packaging & Delivery of Q235 Carbon Steel Sheet Prices Hot Rolled Mild Steel Plate Prices

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

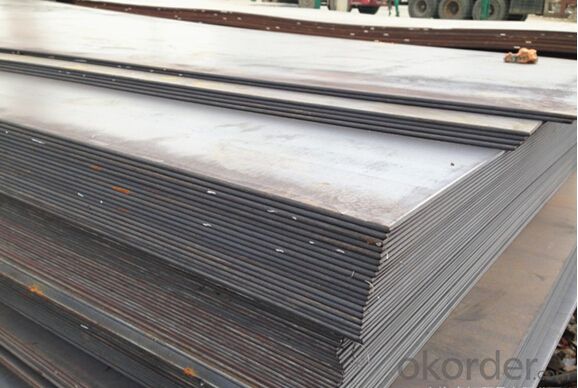

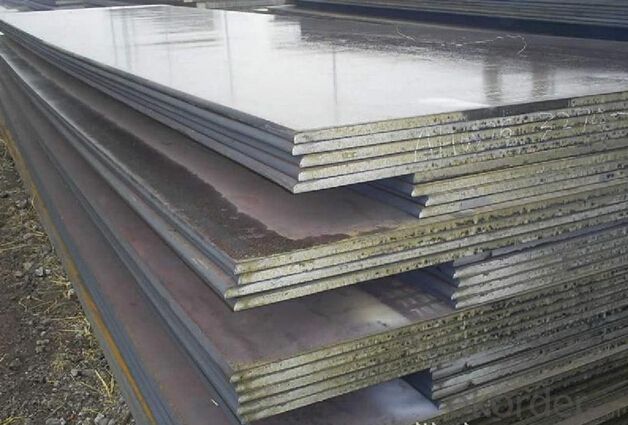

Products Show

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q:What are the different oil and gas grades of special steel?

- There are several different oil and gas grades of special steel that are commonly used in the industry. These grades are specifically designed to withstand the harsh environments and high temperatures associated with oil and gas exploration and production. Some of the most commonly used grades include: 1. API 5CT: This grade is specifically designed for use in casing and tubing applications. It has high strength and excellent resistance to corrosion, making it ideal for use in demanding oil and gas environments. 2. API 5L: This grade is used for pipeline transportation systems in the petroleum and natural gas industries. It has excellent mechanical properties and is designed to withstand high pressure and temperature conditions. 3. NACE MR0175/ISO 15156: This grade is compliant with the NACE MR0175/ISO 15156 standard, which specifies the requirements for the use of metallic materials in oil and gas production environments containing H2S (sour service). These grades have high resistance to sulfide stress cracking and hydrogen-induced cracking. 4. Duplex Stainless Steel: This grade is used in applications where high strength, corrosion resistance, and resistance to stress corrosion cracking are required. It is commonly used in offshore oil and gas production, as well as in subsea equipment. 5. Super Duplex Stainless Steel: This grade offers even higher strength and corrosion resistance than duplex stainless steel. It is commonly used in demanding oil and gas applications, such as subsea and deepwater equipment. These are just a few examples of the different oil and gas grades of special steel available in the market. The selection of the appropriate grade depends on the specific application, operating conditions, and requirements of the project. It is crucial to consult with experts or refer to industry standards and specifications to ensure the right grade is chosen for a particular oil and gas project.

- Q:What are the different forming techniques for special steel?

- Some of the different forming techniques for special steel include forging, rolling, extrusion, and casting.

- Q:What are the specific requirements for special steel used in the textile industry?

- The primary focus when considering the specific needs of special steel used in the textile industry lies in its durability, corrosion resistance, and heat resistance. To maintain its structural integrity, the steel must withstand the harsh conditions and high temperatures involved in textile processing. Firstly, it is essential for the steel used in the textile industry to possess exceptional durability. It must be capable of enduring significant mechanical stress, such as tension, compression, and bending, without experiencing any deformation or breakage. This is crucial due to the constant movement and repetitive actions of the machinery in the textile industry. Another vital requirement is corrosion resistance. The steel must be able to resist corrosion caused by chemicals, moisture, and other environmental factors. This is particularly important as textile manufacturing processes frequently involve the use of various chemicals and water. Heat resistance is also a crucial factor to consider when selecting special steel for the textile industry. Since manufacturing processes involve high temperatures, the steel must be able to withstand and maintain its strength and properties under these conditions. This ensures the longevity and efficiency of the equipment and machinery used in textile production. Additionally, the steel used in the textile industry should exhibit excellent machinability. It should be easy to cut, shape, and form into various components and parts required for textile machinery. This allows for efficient manufacturing and customization of equipment to meet specific needs. Furthermore, the steel may also be required to meet specific standards and certifications established by regulatory bodies or industry organizations. This ensures that the steel meets the necessary quality and safety requirements. For example, it may need to comply with international standards like ISO 9001 for quality management systems. To summarize, the special steel used in the textile industry must meet requirements for durability, corrosion resistance, heat resistance, machinability, and compliance with relevant standards. Meeting these criteria ensures that the steel can withstand the demanding conditions of textile manufacturing and contribute to the efficiency and reliability of the machinery involved.

- Q:What are the limitations of using special steel in electrical applications?

- One limitation of using special steel in electrical applications is its relatively high cost compared to other materials such as copper or aluminum. Special steel also tends to be heavier, which can make electrical components or devices bulkier. Additionally, steel has lower electrical conductivity compared to copper, leading to higher resistance and potential energy losses in electrical circuits. Finally, steel is more susceptible to corrosion, which can impact the durability and longevity of electrical equipment if not adequately protected.

- Q:What are the characteristics of tool steel?

- Tool steel is a type of steel that possesses exceptional hardness, strength, and wear resistance, making it ideal for manufacturing various tools. It typically contains high levels of carbon, along with other alloying elements like chromium, vanadium, and tungsten. Tool steel also exhibits good toughness, heat resistance, and ability to retain sharpness. Additionally, it can be hardened and tempered to achieve desired properties for specific applications.

- Q:What are the different methods of improving the corrosion resistance of special steel?

- Improving the corrosion resistance of special steel can be accomplished through several available methods. Some commonly utilized techniques include: 1. Alloying: Enhancing corrosion resistance can be effectively achieved by alloying the steel with specific elements. For instance, the addition of chromium forms a protective chromium oxide layer on the surface, acting as a barrier against corrosion. Other elements such as molybdenum, nickel, and copper can also be incorporated to enhance corrosion resistance. 2. Surface treatments: Various surface treatments can be employed to augment the steel's corrosion resistance. Galvanizing, for example, involves coating the steel with a layer of zinc, providing protection against corrosion. Another method, electroplating, deposits a thin layer of a more corrosion-resistant metal like nickel or chromium onto the steel surface. 3. Passivation: Passivation is a chemical process that eliminates free iron and other contaminants from the steel surface, resulting in the creation of a passive film that aids in corrosion resistance. This method is frequently used for stainless steel, in which a thin layer of chromium oxide is formed by treating the steel with an oxidizing agent such as nitric acid. 4. Protective coatings: The application of protective coatings on the steel surface significantly enhances its corrosion resistance. Various types of coatings, such as paints, epoxy coatings, and ceramic coatings, act as a barrier between the steel and the corrosive environment, preventing direct contact and corrosion. 5. Heat treatment: Heat treatment techniques, including annealing, quenching, and tempering, can alter the steel's microstructure, thereby enhancing its corrosion resistance. Heat treatment improves the steel's mechanical properties, reduces residual stresses, and eliminates impurities, all of which contribute to better corrosion resistance. 6. Design considerations: Proper design and construction techniques play a crucial role in improving the corrosion resistance of special steel. For instance, the elimination of sharp corners and crevices, the use of appropriate drainage systems, and ensuring proper ventilation can prevent the accumulation of moisture and corrosive agents. It is important to note that the selection of the most suitable method depends on the specific application, environment, and desired level of corrosion resistance. Optimal results can often be achieved by employing a combination of these methods.

- Q:How does special steel contribute to the aerospace safety?

- Special steel contributes to aerospace safety in several ways. Firstly, special steel alloys are used in the construction of various critical components in aircraft, such as engine parts, landing gears, and structural elements. These alloys are specially designed to have high strength, durability, and resistance to fatigue and corrosion, ensuring the structural integrity and longevity of these components, ultimately enhancing the overall safety of the aircraft. Additionally, special steel is often employed in the production of cutting-edge aerospace technologies, including advanced sensors, control systems, and avionics. These technologies play a crucial role in enhancing the safety and performance of aircraft, enabling precise monitoring, efficient communication, and accurate navigation, thus minimizing the risk of accidents. Moreover, the use of special steel in aerospace manufacturing helps to reduce the weight of aircraft, leading to improved fuel efficiency. By utilizing lightweight steel alloys, the overall weight of the aircraft is reduced, increasing its maneuverability and reducing fuel consumption. This, in turn, contributes to enhanced safety by allowing for longer flight durations, increased payload capacity, and improved emergency response capabilities. Overall, special steel's unique properties and applications in aerospace contribute significantly to the safety of aircraft, ensuring their structural integrity, enhancing technological advancements, and improving fuel efficiency, all of which are vital for a safe and reliable aerospace industry.

- Q:How does special steel perform in terms of wear resistance in abrasive environments?

- Special steel performs very well in terms of wear resistance in abrasive environments. Its unique composition and treatment processes enhance its hardness and toughness, making it highly resistant to abrasion caused by particles and friction. This allows special steel to withstand harsh conditions and maintain its integrity for prolonged periods, reducing the need for frequent replacements or repairs.

- Q:What are the common applications of special steel?

- Special steel, also known as alloy steel, finds wide usage across various industries owing to its distinct properties and advantages. Some prevalent applications of special steel are as follows: 1. Automotive industry: In the automotive sector, special steel is extensively employed for the production of engine components such as crankshafts, camshafts, connecting rods, and valves. Its exceptional strength, durability, and resistance to wear render it ideal for enduring the rigorous conditions within internal combustion engines. 2. Aerospace industry: The aerospace industry heavily relies on special steel for manufacturing critical components like landing gear, turbine blades, and structural parts. Its remarkable strength-to-weight ratio, excellent heat resistance, and ability to withstand extreme conditions are indispensable in ensuring the safety and reliability of aircraft. 3. Energy industry: The energy sector, particularly power generation, heavily depends on special steel. It is used in the manufacturing of turbine blades, steam pipes, pressure vessels, and other power plant components. Its capacity to endure high temperatures, pressure, and corrosive environments makes it suitable for these demanding applications. 4. Oil and gas industry: Within the oil and gas sector, special steel is extensively utilized in the production of pipes, valves, fittings, and drilling equipment. Its corrosion resistance and high strength guarantee the secure transportation and extraction of oil and gas in harsh environments. 5. Construction industry: Special steel is commonly employed in the construction sector for various purposes. It is used in the manufacturing of reinforcement bars, structural components, and fasteners. Its high tensile strength, durability, and resistance to corrosion make it an ideal choice for withstanding the loads and environmental conditions encountered in construction projects. 6. Tool and die making: Special steel is widely employed in the production of tools and dies. Its high hardness, wear resistance, and toughness make it suitable for manufacturing cutting tools, molds, dies, and other precision components used across various industries. 7. Medical industry: In the medical sector, special steel is used for the production of surgical instruments, implants, and medical devices. Its biocompatibility, corrosion resistance, and sterilization capabilities make it suitable for these critical applications. In conclusion, special steel finds extensive applications in the automotive, aerospace, energy, oil and gas, construction, tool and die making, and medical industries due to its unique properties and ability to withstand demanding conditions.

- Q:How does special steel contribute to the oil and gas equipment industry?

- Enhanced strength, corrosion resistance, and heat resistance are crucial attributes of special steel, which plays a vital role in the oil and gas equipment industry. This type of steel is specifically engineered to endure the extreme conditions encountered during oil and gas exploration, extraction, and processing. The superior strength of special steel is one of its primary advantages in this industry. Oil and gas equipment, such as drill pipes, wellheads, and pipelines, are subjected to high pressure, heavy loads, and harsh environments. Thanks to its high tensile and yield strength, special steel ensures that these components can withstand such demanding conditions without experiencing failures, thus guaranteeing the safety and reliability of the equipment. Another significant benefit of special steel in the oil and gas equipment industry is its corrosion resistance. The extraction and transportation of oil and gas involve exposure to corrosive substances, such as hydrogen sulfide, carbon dioxide, and saltwater. Special steel is specifically designed to resist corrosion, thereby minimizing the risk of equipment degradation, leaks, and costly maintenance. Furthermore, special steel possesses excellent heat resistance properties. The oil and gas industry often operates equipment at high temperatures during processes such as oil refining, gas compression, or steam injection. The ability of special steel to withstand high temperatures without compromising its mechanical properties makes it an ideal choice for critical components like valves, heat exchangers, and turbines. The use of special steel also enables the oil and gas industry to explore and extract resources from challenging environments. Offshore drilling rigs, for instance, encounter harsh conditions such as strong waves, saltwater exposure, and extreme temperatures. Special steel's resistance to these environmental factors ensures the durability and longevity of offshore equipment. In conclusion, special steel significantly contributes to the oil and gas equipment industry by providing enhanced strength, corrosion resistance, and heat resistance. By employing this type of steel, the industry can ensure the reliability, safety, and longevity of its equipment, ultimately improving operational efficiency and reducing downtime.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Q235 Carbon Steel Sheet Prices Hot Rolled Mild Steel Plate Prices

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords