Hot Rolled Carbon Steel Checker Plate/Sheet Mild Steel Chequer Plate/Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

Commodity Name | GRADES |

Boiler and Pressure Vessel Steel Plates | Q245R,Q345R,Q370R,15CrMoR,18MnMoNbR,13MnNiMoR, 12Cr1MoVR,12Cr2Mo1R,14CrMoR, |

16MnDR,09MnNiDR,15MnNiDR | |

07MnCrMoVR,07MnNiCrMoVDR/12MnNiVR | |

SB410,SB450,SB480 | |

SPV235,SPV315,SPV355,SPV410,SPV490 | |

SGV41O,SGV450,SGV480 | |

SBV1A,SBV1B,SBV2,SBV3 | |

SEV245,SEV295,SEV345 | |

HI,HII,10CrMo910,15Mo3,13CrMo44,19Mn6 | |

BHW35/13MnNiMo54 | |

1Cr0.5Mo,2.25Cr1Mo,1.25Cr0.5Mo,Q245R|Q345R(HIC)/(R-HIC) | |

(s)A229M, (s)A515M(Gr.A,B,C), (s)A387M(GR11,12,22), (s)A537M(GL1,GL2), (s)A662M(GrA,B,C), (s)A302M(GraA,B,C,D), (s)A737M(Gr.B,C), (s)A738M(Gr.A,B,C), (s)A533M(Ⅰ,Ⅱ), (s)A285Gr:A,B,C,D | |

P235GH,P265GH,P395GH,P355GH,16Mo3 | |

A42,A52,A48 | |

20MnHR,Q245HR,Q345HR,KP42,AISI4140,A48CPR,SA612M | |

161G430 | |

WDB620/Q500FC | |

Low Alloy High Strength Steel Plate | 12Mn,15MnVN,16Mn,15MnV,14MnNb |

Q295(A,B),Q345(A,B,C,D,E)Q390(A,B,C,D,E), Q420(A,B,C,D,E),Q460(C,D,E) | |

Q500(D,E),Q550(D,E),Q620(D,E),Q690(D,E) | |

SM490(A,B,C),SM490Y(A,B),SM520(B,C),SM570 | |

St44-3,St52-3,St50-2, St60-2,St70-2 | |

StE315,StE355,StE380,STe420,StE460,StE500 | |

A572M(Gr42.50,60,65),A633M9(A,B,C,D,E) | |

S275(JR,JO,J2G3,J2G4),S355(JR,JO,J2G3,J2G4,E395,E355,E360) | |

S275N,S275NL,S355N,S355NL,S420N,S420NL,S460N,S460NL | |

50(A,B,C,D,DD,EE,F),43(A,B,C,D,EE),55(C,EE,F) | |

Fe430(A,B,C,D),Fe510(B,C,D) | |

WH60,WH410LK(BB41BF),WH490LK(BB503),Q550CFC | |

WDB690,WDB780,WH70,WH80 IE0650,IE1006,SHT60 | |

Corrision Resistance Steel Plate | 08Cu,16MnCu,Q245R|Q345R(HIC)\(R-HIC) |

St37-3Cu3 | |

A588M(A,B,C,K),A242MCL.2 | |

Cor-TenB,10CrMoAL | |

16CuCr,12MnCuCr,15MnCuCr-QT,09CuPCrNi | |

SMA400(AW,BW,CW),SMA400(AP,BP,CP),SMA490(AW,BW,CW) SMA490(AP,BP,CP),SMA570W,SMA570P | |

Fe235W,Fe355W,WR50B,WR50C | |

Bridge Steel Plate | 16q,16Mnq,16MnCuq/15MnVq,15MnVNq 14MnNbp/Q345q,Q370q,Q420q |

A709M(Gr36,50,50W,70W) | |

Construction, Structural Steel Plate | Q235GJ,Q345GJC.D-Z35,Q390GJ,Q460GJC |

SN400(A,B,C),SN490(B,C) | |

275(D,E,EZ),355(D,E,EM),450(EM,EMZ) | |

Alloy Structure Steel Plate | 15CrMo,20CrMo,30CrMo,35CrMo,20Cr, 40Cr,20Mn2,40Mn2,20CrMnMo,12Cr1MoV,20MnSi 30CrMnSiA,12CrMoVNi(RQ65),50Mn2V,42CrMo |

25CrMo4,34CrMo4,42CrMo4 | |

Mold Wear Steel Plate | P20,718,P80,WSM30A |

S45C-S55C | |

45-55,50Mn,SM45-SM55,SM3Cr2Mo,SM3Cr2Mo,SM3Cr2Ni1Mo | |

NM360,NM400 | |

Carbon Structure Steel Plate | Q235-Q275 |

10-55,20Mn-50Mn | |

SS400/SM400(A,B) | |

S10C-S55C | |

St37-2,St37-3 | |

A36,A283(A,B,C,D),1010-1050 | |

40(A,B,C,D,E) | |

S235(JR ,JO ,J2G3,J2G4) | |

1C22,1C25,1C30,1C35,1C40,1C45,1C50,1C55 | |

Fe360(A,B,C,D) | |

Bridge Oil Flatform Steel Plate | A,B,D,E(Z15,Z25,Z35) AH32-FH32(Z15,Z25,Z35) AH36-FH36(Z15,Z25,Z35) |

D40,E40 | |

AP1 SPEC 2H Gr42,Gr50 | |

Complex Steel Plate | TU1/20g 0Cr13Ni5Mo/Q235A 0Cr13Ni5Mo/16Mn |

High Strength Yield Steel Plate | GS80 28Cr2Mo(GY4) 26SiMnMo(GYS) 30CrMnMoRE(603) 30CrNi3MoV(675) |

Oil, Gas Line Steel Plate | X42,X46,X52,X56 X60,X65,X70,X80 |

| Commodity | Cheap Price tear drop checker steel plate Q235B 5.75*1250 steel plate for road Tianjin | ||||||||

| Width | 1250mm or cut to size | ||||||||

| Thickness |

5.75mm | ||||||||

| Surface | coated | ||||||||

| Material | Cheap Price tear drop checker steel plate Q235B 5.75*1250 steel plate for road Tianjin | ||||||||

| Standards | AISI ASTM JIS DIN EN and GB | ||||||||

| Certifications | ISO 9001and SGS | ||||||||

| Applications | All can be used as steel plate | ||||||||

| Packing | Seaworthy wooden pallet or according to client's requirement | ||||||||

| Place of origin | Tianjin, China | ||||||||

| Paymentterms | L/C or T/T | ||||||||

| Delivery time | Up to order quantity | ||||||||

Detailed Images

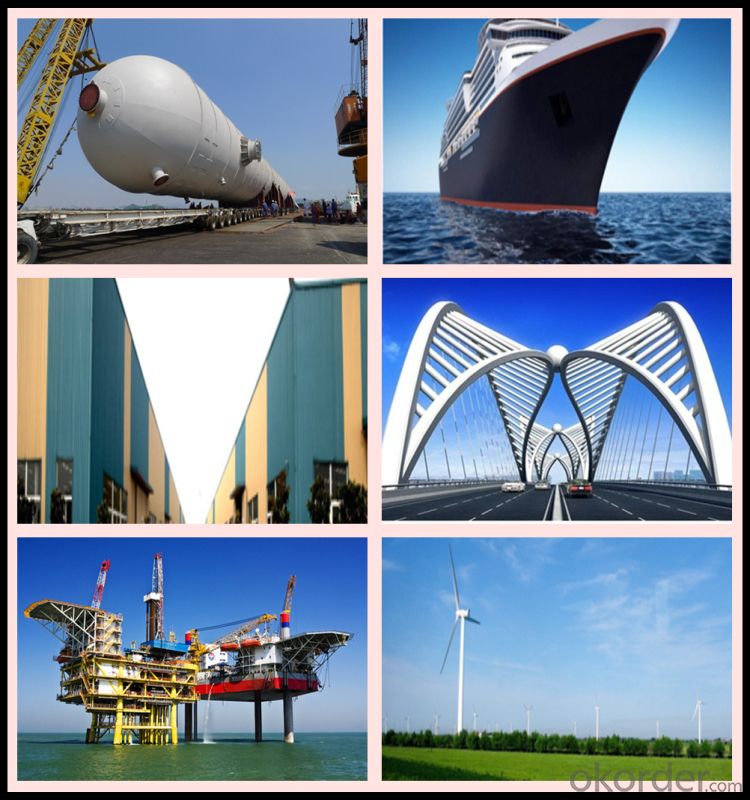

Product Uses

- Q: Are steel coils used in the packaging industry?

- Yes, steel coils are commonly used in the packaging industry for various applications such as strapping, bundling, and securing heavy loads.

- Q: I'm building a single-speed commuter bike and I was wondering what the advantages and disadvantages of steel and alloy wheels are. Any experts out there who can give me specifics for each kind?

- I am a major advocate for steel in bicycle construction, except when it comes to rims. If you are using cantilever or caliper brakes, steel rims are a major no-no, as any moisture greatly reduces your stopping power, practically rendering your brakes useless. Sure, bright chrome rims definitely look nice, but their useful application is extremely limited, and mainly consigned to accurate restorations of antique bikes. If you really want to use chrome steel rims on a bike, make sure you have either disc brakes, drum brakes, or a coaster brake. Aluminum rims have been in use for about 100 years now, and for good reason.

- Q: So i downloaded Broken Steel DLC for Fallout 3 for the 360. My guy is on the level where you have to activate the purifier and when i beat it. It was the normal ending that brought me back to the main menu. My friend said you have to find some guy to talk to but i don't think thats it. Please Help. P.S. i never got and conformation in-game about the download but its under the download sub menu at the main menu.

- after you've downloaded broken steel, while playing in game you should get a message saying, broken steel loaded, then you can make your way to the purifier and finish of the col. and activate it, after-wards you will have to sit through the end movie, which I felt was longer than the original, then the broken steel part will start, which I wont ruin. If your still having problems, go into your DLC and delete broken steel, and re-install it.

- Q: I want to purchase steel for construction purpose, What aspects should I keep in mind while deciding that which company should I contact for this?

- I okorder /

- Q: What are the surface treatments for steel coils?

- Some common surface treatments for steel coils include galvanizing, painting, and coating. These treatments are applied to protect the steel from corrosion, improve its appearance, and enhance its durability.

- Q: How are steel coils inspected for surface defects?

- Steel coils are inspected for surface defects using various techniques such as visual inspection, automated systems, and magnetic particle inspection. Visual inspection involves trained personnel examining the coils for any visible defects or irregularities. Automated systems utilize cameras and sensors to detect defects and anomalies on the coil surfaces. Magnetic particle inspection, on the other hand, involves magnetizing the coil and applying magnetic particles to reveal any surface defects through the formation of visible indications. These methods ensure that steel coils meet quality standards before further processing or shipment.

- Q: What's the difference between hot rolled coil and hot-rolled carbon thin steel coil?

- The difference between hot rolled primary and hot-rolled carbon thin steel coils is that they include carbon steel rolls and low alloy steel coils.

- Q: I heard that the stores don't sale Steel Legion anymore...Is this true..Also I want to know why they cost more than regular Imperial Guardsmen..Such as Cadian...Do they have something Special?Also what do I need to buy to have a complete Steel Legion army..I need two squads of troops of 20's?and two sergeants for each squad.and one commiser?Well I;m guessing..someone please help...I havent played in about 4 years.

- The stock at various shops may vary, but you can buy Steel Legion miniatures through the mail order, or the Internet from GW. Cadian troopers are plastic, There are no plastic Steel Legion troops. The plastic models are (a tiny bit) not so horribly expensive as the metallic ones. The minimum requirements for your force vary from mission to mission, but a good start is 1 HQ unit 2 Troop choices. Also, the total points cost of the battle is to be considered. (Usually 500, 1000, or 1500 points.) What you described is one possible choice, although the size of IG squads is 10 and not 20. And you must include a command squad, the commissar is optional. You might change the other 20 troops for a tank, or a squad of Sentinels. Happy gaming!

- Q: Is this a strong, durable piece of steel that can take abuse? I'm thinking about using it on a small project.

- I think it might be a bit brittle and could break from metal fatigue.

- Q: When maintaining a japanese knife: Is a honing steel still necessary if I have a fine 3000/8000 grit whetstone?which do you prefer?

- A steel is to clean off an edge and remove any bends on the bevel, it is not directly for sharpening as it removes no material from the knife (or should not). A whetstone, however fine, does remove material. A steel to maintain an edge, a stone to restore an edge. They are different items for different purposes.

Send your message to us

Hot Rolled Carbon Steel Checker Plate/Sheet Mild Steel Chequer Plate/Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords