PVDF Coated Aluminum Coil China - Color Coated Aluminum Profile

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Aluminium Profile with PVDF Coated and Color Coated Description:

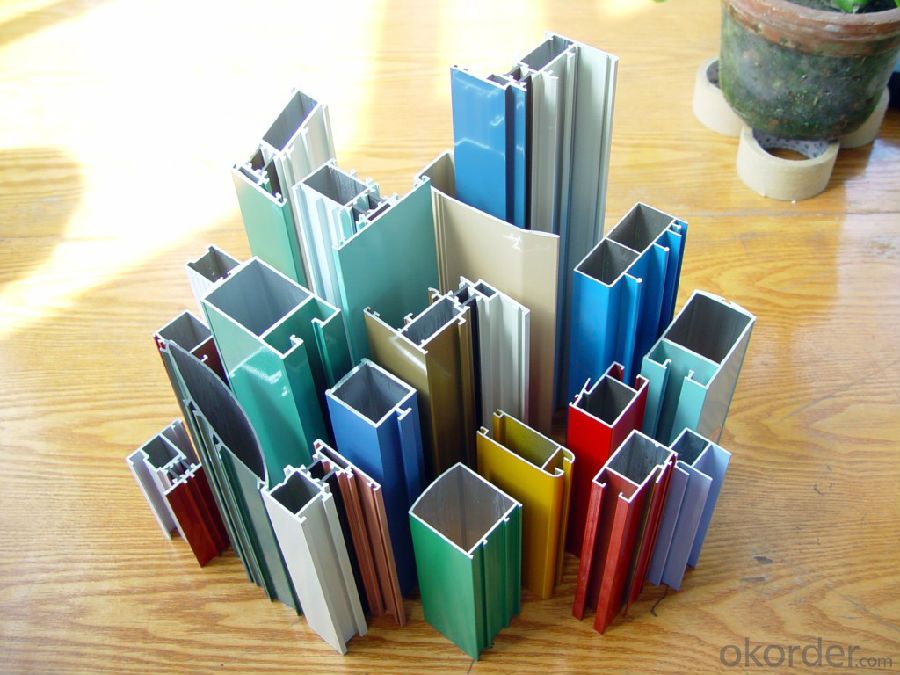

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminium Profile with PVDF Coated and Color Coated:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

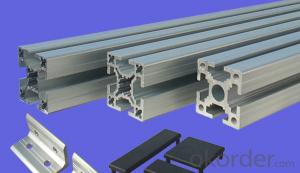

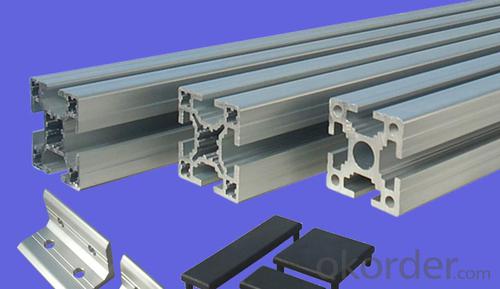

Images of the Aluminium Profile with PVDF Coated and Color Coated:

Aluminium Profile with PVDF Coated and Color Coated Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: Can aluminum coils be used for food storage containers?

- Yes, aluminum coils can be used for food storage containers. Aluminum is a popular choice for food storage containers due to its many beneficial properties. It is lightweight, durable, and has excellent thermal conductivity, meaning it can evenly distribute heat for efficient cooking or cooling. Additionally, aluminum is non-toxic, odorless, and resistant to corrosion, making it a safe option for storing food. It also provides an effective barrier against light, moisture, and oxygen, which helps to preserve the freshness and quality of the stored food. Overall, aluminum coils can be a reliable and practical choice for food storage containers.

- Q: is Aluminum wrotten with a 2 behnd it?

- No, you're thinking of diatomic molecules like dinitrogen and dihydrogen which come in pairs because forming a covalent bond with another atom fills up their electron shell which is what makes them most stable. Metals don't tend to form covalent bonds in bulk but have a kind of ionic bond. You could search for 'metallic bonding' and I imagine some helpful sites would appear. Basically, the electrons are shared, that's what makes metals conductors of electricity. kind regards

- Q: Can aluminum coils be used for electrical conductors?

- Indeed, aluminum coils are capable of serving as electrical conductors. Aluminum, being a metal with exceptional conductivity, finds frequent utilization in electrical contexts. With electrical conductivity ranking second only to copper, aluminum proves to be a fitting material for the conduction of electricity. In numerous electrical apparatuses and setups like transformers, motors, generators, and power transmission lines, aluminum coils are commonly employed.

- Q: Is it possible to construct a portable speaker or speaker docking station using aluminum coils?

- <p>Yes, you can use aluminum coils in the construction of a portable speaker or speaker docking station, but they are not the primary component. Aluminum coils can be used in the speaker's electromagnetic parts, such as in the voice coil of the speaker driver or in the transformer of a docking station. However, the main components of a speaker include a diaphragm, voice coil, magnet, and enclosure, while a docking station would require a connector for the device, an amplifier, and possibly additional circuitry. The aluminum coil's role is to facilitate the magnetic field interaction with the voice coil, which converts electrical signals into sound waves. It's essential to consider the entire design and other necessary components when building such devices.</p>

- Q: If so why does an aluminum bend or get nicked or break quickly?

- NO! You should ask yourself why Tank built with steel rather than using aluminum.

- Q: How are aluminum coils used in the production of HVAC ductwork?

- The production of HVAC ductwork heavily relies on the utilization of aluminum coils. These coils are crafted from top-notch aluminum material that possesses qualities such as being lightweight, long-lasting, and resistant to corrosion, thus making them the perfect choice for HVAC systems. To commence the process of incorporating aluminum coils into HVAC ductwork production, the first step involves manufacturing. Initially, the coils are rolled into thin sheets, which are then precisely cut into specific widths and lengths that match the size requirements of the ductwork. This adaptability in sizing allows for the creation of customized ductwork that fits flawlessly into various HVAC systems. Once the aluminum coils have been cut to the desired dimensions, they are then fashioned into the shape of the ductwork. This can be achieved through a variety of methods, including bending, folding, or rolling, depending on the design and specifications of the ductwork. One of the notable advantages of employing aluminum coils in HVAC ductwork production is their superb thermal conductivity. Aluminum boasts exceptional heat-conducting properties, which means it can effectively transfer heat or cold air throughout the HVAC system. This characteristic is crucial for the proper functionality of the ductwork, as it ensures the desired temperature is maintained in different areas of a building. Furthermore, aluminum coils are renowned for their resistance to corrosion, which is of utmost importance in HVAC systems. The coils are exposed to various elements, such as moisture, which can lead to rust and deterioration in other materials. However, aluminum naturally forms a protective oxide layer that prevents corrosion, guaranteeing the longevity and dependability of the HVAC ductwork. Additionally, the lightweight nature of aluminum coils makes them simple to handle and install. This decreases the labor and time required for ductwork installation, resulting in cost savings for both manufacturers and installation teams. Moreover, the lightweight nature of aluminum coils reduces the overall weight of the HVAC system, making it more energy-efficient and alleviating strain on other components. In conclusion, aluminum coils serve as an integral component in the production of HVAC ductwork. Their lightweight, durable, and corrosion-resistant properties, combined with exceptional thermal conductivity, render them ideal for efficiently circulating air throughout the HVAC system. Furthermore, their flexibility in sizing and ease of installation contribute to their widespread utilization in the HVAC industry.

- Q: Can aluminum coils be painted for custom designs?

- Yes, aluminum coils can be painted for custom designs. Aluminum is a versatile material that can be coated with various paints and finishes, allowing for a wide range of custom design options.

- Q: How do aluminum coils compare to other types of metal coils?

- When comparing aluminum coils to other types of metal coils, there are both advantages and disadvantages. Firstly, aluminum coils are lightweight, making them easier to handle and transport than metals like copper or steel. This lightweight characteristic also contributes to their cost-effectiveness in terms of shipping and installation. Moreover, aluminum coils are highly resistant to corrosion, making them suitable for use in humid or corrosive environments, such as outdoor air conditioning systems or refrigeration units. Additionally, aluminum coils have excellent thermal conductivity, allowing for efficient heat transfer. This makes them highly efficient in applications like HVAC systems or automotive radiators. However, there are also drawbacks to using aluminum coils. Compared to copper coils, aluminum coils have lower electrical conductivity, which can lead to higher energy consumption and reduced efficiency in certain applications. Additionally, aluminum is a softer metal than copper or steel, making aluminum coils more susceptible to damage or bending. To summarize, aluminum coils offer advantages such as lightweight, corrosion resistance, and thermal conductivity. However, they may have lower electrical conductivity and be more prone to damage compared to other types of metal coils. Ultimately, the choice between aluminum coils and other types of metal coils depends on the specific requirements of the application.

- Q: What are the different color options for anodized aluminum coils?

- Anodized aluminum coils offer a wide range of color options to choose from. The anodization process involves immersing the aluminum in an electrolyte solution and applying an electric current to create a protective oxide layer on the surface. This oxide layer can be dyed in various colors, allowing for customization and aesthetic enhancement. Some common color options for anodized aluminum coils include silver, black, bronze, gold, copper, and champagne. These colors are achieved by using different dye solutions during the anodization process. Additionally, there are also various shades and finishes available within each color category, providing further versatility and choice. The color options for anodized aluminum coils are not limited to solid colors only. It is also possible to create patterns, gradients, or even custom designs by applying masking techniques or utilizing advanced printing technologies. This allows for even more creative freedom and the ability to match specific branding or design requirements. Furthermore, anodized aluminum coils offer excellent color retention and durability. The anodized oxide layer not only provides protection against corrosion and wear but also acts as a base for the dyed color, resulting in long-lasting and vibrant finishes. In summary, the different color options for anodized aluminum coils are extensive and diverse, ranging from traditional metallic finishes to bold and unique shades. This variety allows for endless possibilities in architectural, industrial, and decorative applications, ensuring that there is a suitable color option for every project.

- Q: Are aluminum coils suitable for beverage can manufacturing?

- Yes, aluminum coils are suitable for beverage can manufacturing. Aluminum is a preferred material for beverage cans due to its various advantageous properties. Firstly, aluminum is lightweight, which makes it easy to transport and handle. This is particularly important for the beverage industry, where large quantities of cans are produced and distributed. Additionally, aluminum is highly malleable, allowing it to be formed into the desired shape without losing its structural integrity. This makes it ideal for can manufacturing, as it can be easily shaped into a can's cylindrical form and withstand the pressure from carbonated beverages. Moreover, aluminum is a non-toxic material, ensuring that it does not contaminate the beverages stored in the cans. It also provides a barrier against light, oxygen, and moisture, which helps to preserve the taste and quality of the beverages. Furthermore, aluminum is recyclable, making it an environmentally friendly choice for can manufacturing. The recycling process for aluminum requires significantly less energy compared to producing new aluminum, making it a sustainable material option. Overall, the suitability of aluminum coils for beverage can manufacturing is evident due to its lightweight nature, malleability, non-toxicity, preservation properties, and recyclability.

Send your message to us

PVDF Coated Aluminum Coil China - Color Coated Aluminum Profile

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords