China Color Coated Aluminum Coil - Aluminium Profile Glass Wall Usage with Best Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

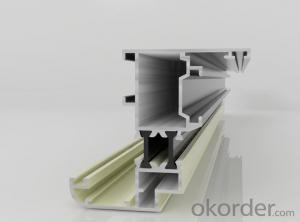

Structure of Aluminium Profile Glass Wall Usage and Best Quality Description:

We have more than 10 years experiences on manufacturing kinds of aluminum profiles, such as Aluminum Window & Door profiles, Aluminum tile trim profiles, Aluminum profiles for LED light, Round/Square General profiles, Aluminum heat sink, Aluminum heating insulation profiles, Curtain wall Aluminum profiles, and others Industry profiles.

Our products have exported to all over the world, and we also have a large of market share in Algeria, Angola, Philippine, Guinea, Ghana, South Africa, Nepal, Nigeria, Tanzania, Iraq etc.

Main Features of the Aluminium Profile Glass Wall Usage and Best Quality:

1, Strong R&G: help customers finalize the design, strong tool design ability, excellent, pressing and surface treatment technology;

2, Strong quality management: ISO&SGS SYSTEM;

3, 24 hours on-line communication, professional, patient, flexible;

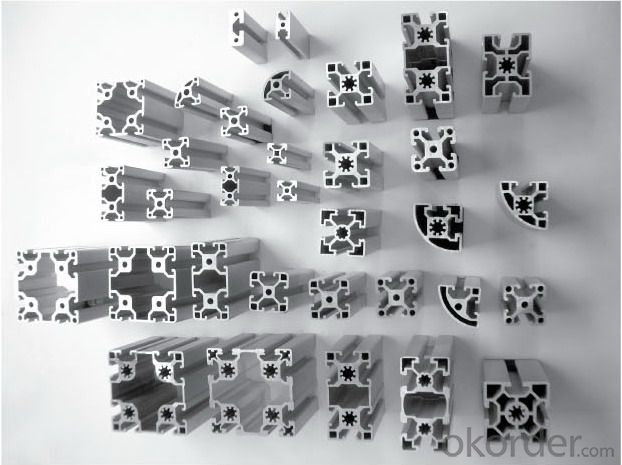

4, High capacity of manufacturing and wide range of products;

5, We can provide secondary manufacturing.

6, High corrosion resistance, high weather resistance and good wear resistance.

7, Alternative surface treatment: Colorful ANODIZE, POWDER COATING, ELECTROPHORESIS & WOODEN GRAIN. Plentiful colors upon your needs.

8, Excellent material for smooth and subtle edges, elegant appearance.

9, Strong coated adhesion which is suitable for construction and industrial material.

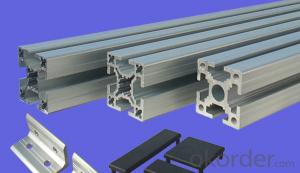

Images of the Aluminium Profile Glass Wall Usage and Best Quality:

Aluminium Profile Glass Wall Usage and Best Quality Specification:

Material | Alloy Aluminum 6063,6061,6005 or customer nominated |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Colour | Any colour based on Standard Germany RAL Mark |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Press Machine | 500-4000 tons all together 64 press lines. |

Fabrication | 1. Windows and doors; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO 9001 |

Moulding | 1. Using our moulds, no fee; |

2. Using customer drawing, opening mould, usually about 10~50 tons then the moulding can be refunded. | |

3. Mould cost is negotiable base on the order quantity | |

Capability | Annual output 100,000 tons |

FAQ:

1.Q: What about leadtime ?

A: Normally the leadtime is 60days after we receive the deposit and confirm the details. All the press machines we use is the best quality in China Yangli brand. The press machine leadtime from Yangli is 50days, the best leadtime we can give is 60days.

2.Q: What's the lead time for moulds?

A: Normally the mould leadtime is 45 days after we confirm all the details with customer. Our professional mechanical enginners from Austria will design the mould according to the samples from customer, or by the specifications offered by customers.

3.Q:What kinds of mould you can make? and what is your strong point for the moulds?

A: we can make wrinkle wall mould and smooth wall mould both. For wrinkle wall mould we can make, 79" pan, fish pan, bbq pan. For smooth wall mould we can make muffin cup, and cake cup, tar cup,etc. We can also make 2 or 3 portion conatiner moulds as long as you offer us sample or specifications. Our strong points are all our moulds are WEDMLS cut, which makes the mould more accurate and precise. Important materials likestainless steel parts we make in Austria. We also recut after heat treatment, which most of makers do not take this process.

- Q: How do aluminum coils contribute to reduced material waste?

- There are several ways in which aluminum coils contribute to the reduction of material waste. Firstly, aluminum is a material that can be recycled multiple times without losing its properties. This recyclability feature alone helps to reduce material waste as it eliminates the need for extracting and producing new aluminum. Moreover, industries that require precision and efficiency, such as automobile manufacturing, HVAC systems, and electrical equipment, often utilize aluminum coils. These coils can be easily tailored to meet specific requirements, minimizing the use of excess material and reducing waste. Furthermore, aluminum coils have a high strength-to-weight ratio, meaning they can be manufactured using less material while still maintaining the desired strength and durability. This lightweight characteristic not only reduces material waste but also allows for more efficient transportation and installation processes, resulting in lower fuel consumption and less environmental impact. In addition, aluminum coils can be designed to have a longer lifespan and improved resistance to corrosion. This durability factor helps to minimize the need for frequent replacement, thereby reducing material waste over time. Furthermore, the long lifespan of aluminum coils makes them an appealing choice for sustainable construction practices, further contributing to waste reduction in the long term. Overall, the utilization of aluminum coils in various industries not only promotes recycling and reusability but also enables efficient customization, lightweight construction, enhanced durability, and extended lifespan. These factors collectively contribute to the reduction of material waste, making aluminum coils an environmentally-friendly option.

- Q: Please tell me the the size of the piece of aluminum that you give the weight messurements.

- This Site Might Help You. RE: How much does Pure Aluminum weight, and what is its density or durability? Please tell me the the size of the piece of aluminum that you give the weight messurements.

- Q: Are there any restrictions on the coil thickness of aluminum coils?

- Yes, there are typically restrictions on the coil thickness of aluminum coils. The specific restrictions may vary depending on the intended application and industry standards. Generally, the thickness of aluminum coils is limited by the capabilities of the manufacturing equipment and the desired final product. Thinner coils are often preferred for applications that require flexibility, such as in the manufacturing of foils or flexible packaging materials. On the other hand, thicker coils are commonly used in industries like construction or automotive, where strength and durability are important factors. Additionally, the thickness of aluminum coils may be restricted by the availability and cost of raw materials. It is important for manufacturers to adhere to these restrictions to ensure the quality and performance of the final product.

- Q: What is the hardness of aluminum coils?

- The hardness of aluminum coils is subject to change due to several factors, including the particular alloy employed and the applied tempering process. Typically, in comparison to other metals, aluminum coils exhibit relatively low hardness. Aluminum is esteemed for its lightweight and pliable characteristics, rendering it effortlessly bendable and moldable. Nevertheless, by subjecting aluminum coils to diverse heat treatment methods like annealing or cold working, their hardness can be augmented to fulfill specific criteria. It should be emphasized that the hardness of aluminum coils can also fluctuate depending on the intended purpose and the desired degree of robustness and endurance.

- Q: What are the different packaging options for aluminum coils?

- There are various packaging options available for aluminum coils to ensure their safety and convenience during transportation and storage. Some common packaging options include: 1. Wooden Crates: Aluminum coils are often packaged in wooden crates, which provide excellent protection against impacts and ensure the coils remain intact during transit. The crates are typically reinforced with steel bands for added strength and stability. 2. Cardboard Boxes: Smaller aluminum coils or coils intended for retail purposes are often packaged in cardboard boxes. These boxes are lightweight, cost-effective, and provide moderate protection against minor impacts. 3. Plastic Wrapping: Aluminum coils can also be wrapped in plastic film, which helps protect them from moisture, dust, and scratches. This packaging option is commonly used for coils that are transported in bulk or in situations where additional packaging is not required. 4. Metal or Composite Tubes: In some cases, aluminum coils are packaged in metal or composite tubes. These tubes are sturdy and provide excellent protection against external forces. They are often used for coils with large diameters or longer lengths. 5. Customized Packaging: Depending on the specific requirements of the customer or industry, customized packaging options can be designed. This may include the use of foam or cushioning materials to provide additional protection, or the incorporation of specialized features such as moisture-resistant barriers. It is important to choose packaging options that best suit the specific needs of the aluminum coils, considering factors such as coil size, weight, transportation conditions, and storage requirements.

- Q: Can aluminum coil 3003H24 replace 3A21H14?

- Yes.

- Q: Are aluminum coils available in different colors?

- Aluminum coils come in various colors, offering a plethora of design and aesthetic possibilities for different applications. To achieve these colors, the surface of the aluminum coils is coated with a long-lasting finish, which can be found in different hues. This coating process, known as coil coating, involves thoroughly cleaning and pre-treating the aluminum coils before applying a layer of paint or other colored material. Consequently, a wide array of colors can be applied to the aluminum coils, allowing for flexibility in design and aesthetic preferences.

- Q: Can aluminum coils be used in the production of sporting goods?

- Sporting goods production can involve the use of aluminum coils, a lightweight and durable material commonly found in the manufacturing of baseball bats, tennis rackets, golf clubs, and bicycles. These coils are often employed as a raw material during the production process, helping to shape and structure the final sporting goods. The utilization of aluminum in sporting goods provides several benefits, including improved performance, increased durability, and enhanced weight distribution. Furthermore, aluminum's resistance to corrosion makes it an excellent choice for outdoor sporting activities. Ultimately, the versatility, strength, and performance-enhancing capabilities of aluminum coils contribute to their widespread use in the production of sporting goods.

- Q: This question asks for a comparison of the pros and cons of utilizing steel coils in construction projects.

- <p>Advantages of using steel coils in construction include their high strength and durability, which allows for the creation of robust structures. They are also resistant to corrosion and can withstand harsh weather conditions. Steel coils are versatile and can be easily shaped and welded, making them suitable for a variety of construction applications. Additionally, they are recyclable, contributing to sustainability efforts. Disadvantages include the initial high cost of steel coils compared to some other materials, and the potential for rust if not properly maintained. Steel structures may also require more frequent inspections and maintenance due to the risk of corrosion over time, especially in coastal or humid environments.</p>

- Q: for purchasing aluminium are the grades to be mentioned

- Aluminum alloy designations are described by a 4-digit index system. The first digit indicates the alloy group according to the major alloying elements. 1XXX - 99% Al with no major alloying element. 2XXX – copper 3XXX – Manganese 4XXX – Silicon 5XXX – Magnesium and silicon 7XXX – Zinc 8XXX – other element Experimental alloy designations have an “X” prefix Aluminum temper designations (suffixes) describe heat-treatable and non heat-treatable alloys.

Send your message to us

China Color Coated Aluminum Coil - Aluminium Profile Glass Wall Usage with Best Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords