Aluminum PVDF Solid Color Coated Coil Rolls

- Loading Port:

- Yantai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of PVDF Aluminum Coil for ACP Description:

PVDF coated aluminum coils are specially processed through the technics of roller coating and baking with precise paints from BECKER INDUSTRIAL COATINGS in Sweden and THE VALSPAR CORPORATION in USA. The main material of PVDF is polyvinylidene fluoride resin; the utmost negative characteristic of the Fl atom can form a very strength high powerful Fl-C bond. Moreover, with the special symmetry molecule structure, the products are of strong weather resistance performance, anti-ultraviolet performance, super long durability and anti-corrosion performance, which can maintain very bright and glossy color even serving for 20 years in outdoor environment. Attributing to the abrasion resistance and impact resistance and flexibility, our products are of excellent mechanical processing performance.

PVDF coated aluminum coils are the highest priority of choice to high class aluminum composite panels, and its composite products are widely used in airport, exhibition center, administration center, star hotel and other symbol building.

2.Main Features of the Aluminum PVDF Coated Coil:

• Light Weight

• High Flatness

• Protecting Environment

• Good Weathering

• Colorful

• Recycling

• Saving Energy

• Rustproof

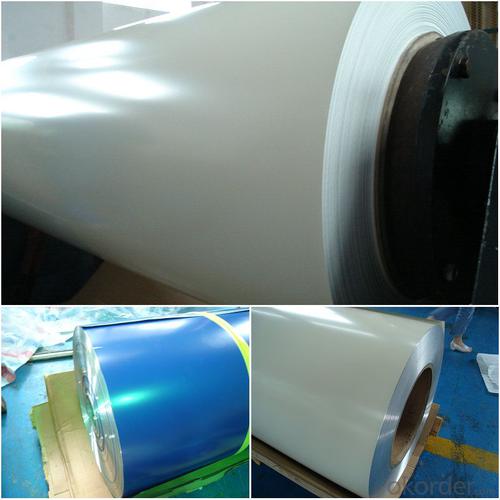

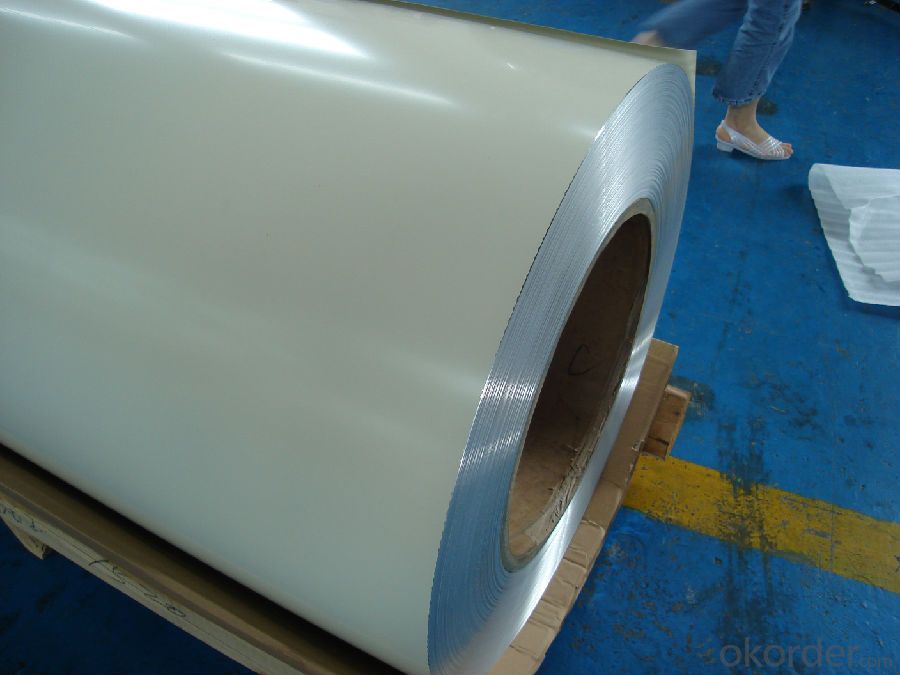

3.Aluminum PVDF Coated Coil Images:

4.Aluminum PVDF Coated Coil Specification:

Aluminum Thickness | Coating Thickness | MEK | T Bend | Impact | Adhesion | Pencil Hardness | Boiling Water Proof |

0.3-1.5mm | ≥25μm | ≥100 Times | ≤2T | 50kg•cm No falling.No crack | 0 Grade | ≥1H | no change within 2 hours |

0.15-0.28mm | ≥25μm | ≥100 Times | ≤2T | 20kg•cm No falling.No crack | 0 Grade | ≥1H | no change within 2 hours |

PVDF Aluminum Coil for ACP

Features of PVDF Aluminum Coil:

1. Adopting precision rolling coating technology, our PE coated coil can ensure excellent adhesive without coating omission.

2. For the PVDF coated aluminum sheet we produced, there are various colors for your choice.

3. Using infrared heating technology to protect environment from pollution.

4. Our coated aluminum coil has four-roller coating line, uniform coating thickness and good features.

Raw Material of the PVDF Coated Aluminum Coil:

1. Aluminum Coil: high strength aluminum with alloy of AA1100 (aluminum alloy is available with AA3003, AA3005, AA5005 according to customer)

2. Surface Paint: PE, PVDF and special paints.

Specification of the PVDF Coated Aluminum Coil:

Width: 20mm~1590mm

Thickness: 0.06mm~1.0mm

External Diameter: ≤ 1500mm

Internal Diameter: 405mm, 505mm, 150mm, 75mm

Coil weight: ≤ 4000kg

5.FAQ

1. Color of Card

Our PVDF coated aluminum coil is made of fluorine carbon resin, pigment, ester solvent after high temperature roasting and baking. The paint of this PVDF coated aluminum coils are solidified to dry film with super weather resistance. PVDF coating also can be classified as traditional PVDF and nanometer PVDF coating.

A. Traditional PVDF Coating, with KYNAR500 PVDF and two or three times for coating and baking, has good properties of anti-acid, anti-alkali and is durable in atrocious weather and environment, keeping 15 years no unwonted fading. In view of these facts, we recommend this PVDF coated aluminum coils are applied for external wall cladding.

B. Nanometer PVDF Coating, which different with traditional PVDF, is the clear coating. It contains nanometer element, which can protect panel from pollution, because nanometer has self-cleaning effect, it is easy to get rid of dust and pollution by raining or water.

2. Color Match

For custom' color requests, we can deal as following:

1. Supply a physical sample of custom color. A color sample on metal is preferred. If other, it is also acceptable. But the color matching rate may be not good as color on metal.

2. New color sample is usually offered by our paint supplier in 5-7 days, special color should be in 7-10 days.

3. Upon receipt of color sample, please approve in writing as soon as possible. Once you approved, we will arrange purchasing and production.

Note: Color difference maybe occurred in different production batch, so it is suggested all panels are placed in one order for same project. And keep same direction as arrow on protective film when installing to avoid any color difference by vision.

3.How long can we receive the product after purchase?

15-20days for general specification and 35days for special specification after receiving the deposit.

- Q: Is the accumulation of aluminum in the body harmful to health?

- <p>Aluminum buildup in the body has been a subject of concern, particularly in relation to Alzheimer's disease. While aluminum is naturally present in the environment and is used in various products, including food packaging and cookware, there is no strong scientific evidence to support the claim that aluminum exposure or accumulation causes health problems in humans. The World Health Organization and other health authorities have stated that aluminum intake from food and drinking water is not a significant health risk for the general population. However, it is always recommended to follow good hygiene practices and use cookware that is known to be safe for food preparation to minimize any potential risks.</p>

- Q: Can reusing old aluminum foil be utilized for cleaning tasks in kitchen or bathroom areas?

- <p>Yes, old aluminum foil can be used for cleaning purposes in a kitchen or bathroom. It's particularly effective for scrubbing pots and pans, removing burnt-on food, and cleaning glass and tiles. The shiny side of the foil can be used to remove scuff marks from floors and the dull side can be used to scrub away stubborn stains. However, it's important to avoid using foil that has been in contact with acidic or corrosive substances, as it may have become damaged or weakened, and could potentially scratch surfaces. Always test on a small, inconspicuous area first to ensure it doesn't damage the surface you're cleaning.</p>

- Q: Explain how the strength of aluminum is affected by temperature changes.

- <p>The strength of aluminum decreases with increasing temperature. As temperature rises, aluminum undergoes thermal expansion, which can lead to a reduction in its yield strength and tensile strength. This is because the increased thermal energy causes the aluminum atoms to vibrate more, weakening the metallic bonds. At very high temperatures, aluminum can become ductile and may even lose its structural integrity. Conversely, at very low temperatures, aluminum can become brittle, which also affects its strength negatively. Therefore, the optimal temperature for maintaining the strength of aluminum is typically within its normal operating range.</p>

- Q: This question asks for an explanation of the steps involved in producing aluminum.

- <p>The production process of aluminum primarily involves two stages: extraction from bauxite and refining. Initially, bauxite ore, the primary source of aluminum, is mined and then processed to remove impurities. The refined bauxite is then mixed with a hot caustic soda solution in a process called the Bayer Process, which extracts aluminum oxide (alumina). In the second stage, alumina is dissolved in molten cryolite and subjected to an electrolytic reduction process in a Hall-H茅roult cell. This involves passing an electric current through the molten mixture, causing the aluminum oxide to decompose and release pure aluminum, which collects at the bottom of the cell. The aluminum is then tapped off, cooled, and cast into various forms for further processing or use.</p>

- Q: Is it possible to utilize aluminum in the construction or components of electronic devices?

- <p>Yes, aluminum is commonly used in electronic devices. It is valued for its lightweight, high thermal conductivity, and corrosion resistance. Aluminum is often used in heat sinks to dissipate heat from electronic components, as well as in the casings of devices for structural support and durability. Additionally, aluminum is used in the manufacturing of electrolytic capacitors and serves as a conductive material in various electronic components due to its good electrical conductivity.</p>

- Q: This question asks about the consequences of corrosion on aluminum, including how it affects the material's properties and performance.

- <p>Corrosion on aluminum can lead to a loss of structural integrity, reduced strength, and increased brittleness. It can cause pitting, which is localized corrosion that leads to the formation of small holes or cavities on the surface. Over time, this can lead to material failure. Corrosion can also alter the appearance of aluminum, causing discoloration and a rough texture. In extreme cases, it can lead to the complete degradation of the aluminum, resulting in the loss of the material's functionality. Proper maintenance, such as applying protective coatings or using corrosion-resistant aluminum alloys, can mitigate these effects.</p>

- Q: Jiangsu in addition to the 10000 aluminum factory, there are no other aluminum factory?

- Jiangyin Xinyu company specializing in the production of various types of building Aluminum Alloy industrial profiles, A Well-Known Trademark in China, national inspection, Jiangsu famous brand, my ID address after the two to 52 is my mobile phone number, welcome to contact with us, thank you!

- Q: Is it possible to enhance the efficiency of solar panels by utilizing aluminum?

- <p>Yes, aluminum can be used to improve the efficiency of solar panels. Aluminum is lightweight, corrosion-resistant, and has good thermal conductivity, which can help in dissipating heat and maintaining optimal operating temperatures for solar cells. It is also used in the manufacturing of solar panel frames, providing structural support while reducing the overall weight of the panels. Additionally, some research suggests that using aluminum in the backsheet of solar panels can enhance their durability and efficiency. However, the extent of efficiency improvement depends on various factors, including the specific design and manufacturing process of the solar panels.</p>

- Q: Explain the impact of aluminum on the transportation system when it is incorporated into automobiles.

- <p>Aluminum has a significant impact on the transportation system when used in automobiles. It is lightweight, which improves fuel efficiency by reducing the overall weight of the vehicle. This reduction in weight leads to lower emissions, as less fuel is consumed. Aluminum's durability and resistance to corrosion also contribute to the longevity of vehicles, reducing the need for frequent repairs or replacements. Additionally, aluminum's recyclability helps in reducing waste and conserving resources, which is beneficial for environmental sustainability. Overall, the use of aluminum in automobiles enhances performance, reduces environmental impact, and promotes a more sustainable transportation system.</p>

- Q: Dangemen mills and other Aluminum Alloy and enterprises what is the difference?

- I looked at the statistics, found that Aluminum Alloy door enterprises Dangemen factory is the only one focused on the balcony. Other aluminium door enterprises cover many other products. This can be said to be the most obvious difference Dangemen factory and other enterprises.

Send your message to us

Aluminum PVDF Solid Color Coated Coil Rolls

- Loading Port:

- Yantai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords