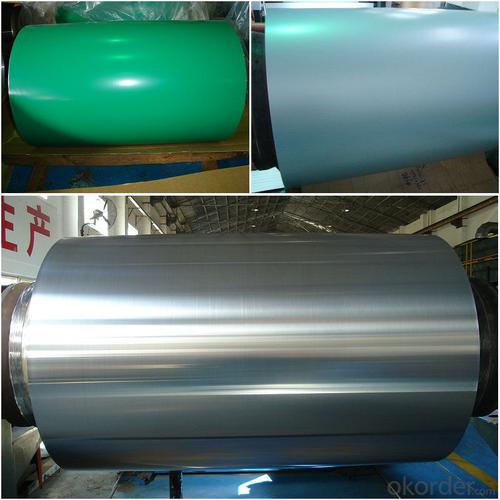

PVDF and PE Color Coated Aluminum Lattice Sheets Coil Rolls

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Features of PVDF AluminumCoil:

1. Adopting precision rollingcoating technology, our PE coated coil can ensure excellent adhesive withoutcoating omission.

2. For the PVDF coatedaluminum sheet we produced, there are various colors for your choice.

3. Using infrared heatingtechnology to protect environment from pollution.

4. Our coated aluminum coilhas four-roller coating line, uniform coating thickness and good features.

Raw Material of the PVDFCoated Aluminum Coil:

1. Aluminum Coil: highstrength aluminum with alloy of AA1100 (aluminum alloy is available withAA3003, AA3005, AA5005 according to customer)

2. Surface Paint: PE, PVDF andspecial paints.

Specification of the PVDFCoated Aluminum Coil:

Width: 20mm~1590mm

Thickness: 0.06mm~1.0mm

External Diameter: ≤ 1500mm

Internal Diameter: 405mm,505mm, 150mm, 75mm

Coil weight: ≤ 4000kg

Performance and usage

PVDF coated aluminum coils are specially processedthrough the technics of roller coating and baking with precise paints fromBECKER INDUSTRIAL COATINGS in

Performance of the coating

Aluminum Thickness | Coating Thickness | MEK | T Bend | Impact | Adhesion | Pencil Hardness | Boiling Water Proof |

0.3-1.5mm | ≥25μm | ≥100 Times | ≤2T | 50kg•cm | 0 Grade | ≥HB | no change within 2 hours |

0.15-0.28mm | ≥25μm | ≥100 Times | ≤2T | 20kg•cm | 0 Grade | ≥HB | no change within 2 hours |

Color of Card

Our PVDF coated aluminum coil is made offluorine carbon resin, pigment, ester solvent after high temperature roastingand baking. The paint of this PVDF coated aluminum coils are solidified to dryfilm with super weather resistance. PVDF coating also can be classified astraditional PVDF and nanometer PVDF coating.

A. Traditional PVDF Coating, with KYNAR500 PVDF and two or three times forcoating and baking, has good properties of anti-acid, anti-alkali and isdurable in atrocious weather and environment, keeping 15 years no unwontedfading. In view of these facts, we recommend this PVDF coated aluminum coilsare applied for external wall cladding.

B. Nanometer PVDF Coating, which different with traditional PVDF, is the clearcoating. It contains nanometer element, which can protect panel from pollution,because nanometer has self-cleaning effect, it is easy to get rid of dust andpollution by raining or water.

Color Match

For custom' color requests, we can deal as following:

1. Supply a physical sample of custom color. A color sample on metal ispreferred. If other, it is also acceptable. But the color matching rate may benot good as color on metal.

2. New color sample is usually offered by our paint supplier in 5-7 days,special color should be in 7-10 days.

3. Upon receipt of color sample, please approve in writing as soon as possible.Once you approved, we will arrange purchasing and production.

Note: Color difference maybe occurred in different production batch, soit is suggested all panels are placed in one order for same project. And keepsame direction as arrow on protective film when installing to avoid any colordifference by vision.

PE Aluminum Coating Coils for ACP

Featuresof PE Aluminum Sheet:

1.Adopting precision rolling coating technology, our PVDF and PE coated coil canensure excellent adhesive without coating omission.

2. For thePE coated aluminum coil we produced, there are various colors for your choice.

3. Usinginfrared heating technology to protect environment from pollution.

4. Ourcoated aluminum coil has four-roller coating line, uniform coating thicknessand good features.

RawMaterial of the PE Aluminum Coating Coils:

1. Aluminum Coil: high strength aluminum withalloy of AA1100 (aluminum alloy is available with AA3003, AA3005, AA5005according to customer)

2. Surface Paint: PE, PVDF and specialpaints.

Specification of PE Aluminum Coating Coil

Width: 20mm~1590mm

Thickness: 0.06mm~1.0mm

External Diameter: ≤ 1500mm

Internal Diameter: 405mm, 505mm, 150mm, 75mm

Coil weight: ≤ 4000kg

PE coated aluminum coil is processed throughthe technics of roller coating and baking with precise polyester paints. Itscolor is glossy and with variety of colors enabling you to choose easily.Chromatic aberration is small, impact resistance is strong and easy to beprocessed, and all its performance has reached or surpassed the nationalcriteria. The products are widely used in indoor and door decoration, ceilings,room surface tiles, corrugated boards, wallpanels, advertisement boards, counters, home appliances, decoration in and outof autos and boats.

Performance of thecoating

Aluminum Thickness | Coating Thickness | MEK | T- Bend | Impact | Adhesion | Pencil Hardness | Boiling Water Proof |

0.3-1.5mm | ≥18μm | ≥100 Times | ≤2T | 50 kg•cm | 0 Grade | ≥HB | no change within 2 hours |

0.2-0.28mm | ≥18μm | ≥100 Times | ≤2T | 30kg•cm | 0 Grade | ≥HB | no change within 2 hours |

0.15-0.18mm | ≥18μm | ≥100 Times | ≤3T | 20 kg•cm | 0 Grade | ≥HB | no change within 2 hours |

0.08-0.12mm | ≥16μm | ≥80 Times | ≤4T | 10 kg•cm | ≤1 Grade | ≥HB | no change within 1 hour |

0.022-0.06mm | ≥12μm | ≥50 Times | - | - | ≤1Grade | ≥HB | no change within1 hour |

Color of Card

PE (polyester)

PE

Color Match

For custom' color requests, we can deal as following:

1. Supply a physical sample of custom color. A color sample on metal ispreferred. If other, it is also acceptable. But the color matching rate may benot good as color on metal.

2. New color sample is usually offered by our paint supplier in 5-7 days,special color should be in 7-10 days.

3. Upon receipt of color sample, please approve in writing as soon as possible.Once you approved, we will arrange purchasing and production.

Note: Color difference maybe occurred in different production batch, so it issuggested all panels are placed in one order for same project. And keep samedirection as arrow on protective film when installing to avoid any colordifference by vision

- Q: Can aluminum sheets be used for sound barriers?

- Yes, aluminum sheets can be used for sound barriers. Aluminum is a lightweight and durable material that can effectively reflect and absorb sound waves, making it suitable for creating sound barriers in various applications.

- Q: What are the different types of surface treatments available for architectural aluminum sheets?

- There are several different types of surface treatments available for architectural aluminum sheets. These treatments are designed to enhance the appearance, durability, and performance of the aluminum, making it suitable for a wide range of architectural applications. One common type of surface treatment is anodizing. Anodizing involves immersing the aluminum sheet in an electrolytic solution and applying an electric current to create a protective oxide layer on the surface. This oxide layer can be dyed to achieve a desired color or left clear for a natural metallic appearance. Anodized aluminum sheets are known for their excellent corrosion resistance, scratch resistance, and color stability. Another type of surface treatment is powder coating. Powder coating involves applying a dry powder electrostatically to the aluminum sheet and then curing it in an oven. The powder melts and fuses to the surface, creating a smooth and durable finish. Powder coating provides excellent color retention, weather resistance, and resistance to chipping and cracking. A third type of surface treatment is PVDF coating. PVDF (polyvinylidene fluoride) coating is a high-performance fluoropolymer resin that is applied to the aluminum sheet through a coil coating process. PVDF coatings offer exceptional resistance to fading, chalking, and chemical attack, making them ideal for exterior applications where color retention and durability are key. Additionally, there are various mechanical surface treatments available for architectural aluminum sheets. These treatments, such as brushing or polishing, can provide a desired texture or reflectivity to the surface. Mechanical treatments can be used to create a brushed, satin, or mirror-like finish, adding aesthetic appeal to the aluminum sheet. In summary, the different types of surface treatments available for architectural aluminum sheets include anodizing, powder coating, PVDF coating, and mechanical treatments. Each treatment offers unique benefits and characteristics, allowing architects and designers to choose the most suitable option for their specific project requirements.

- Q: What are the weight considerations when using aluminum sheets?

- When using aluminum sheets, weight considerations are important due to the lightness of aluminum. It is crucial to determine the thickness and size of the sheet based on the intended application to ensure structural integrity and proper load-bearing capacity. Additionally, the weight of aluminum sheets may affect transportation, installation, and overall handling requirements.

- Q: Where does China make aluminum plate?

- In many parts of the country have aluminum factory, the old state-owned enterprises have 101, SWA aluminum plant, located in the southwest, northeast china. The emerging aluminum processing base in Henan, due to resource advantages, the largest aluminum factory, the price is relatively low.

- Q: is there any kind of deoderant, other than those crystals that smell, that don't have aluminum in it?

- Mennen makes a line of plain old deodorant. They also make antiperspirants, though, so be sure you read the label.

- Q: Can aluminum sheets be anodized for improved corrosion resistance?

- Yes, aluminum sheets can be anodized to enhance their corrosion resistance. Anodizing is an electrochemical process that creates a protective oxide layer on the surface of the aluminum, making it more resistant to corrosion and increasing its durability.

- Q: How do aluminum sheets perform in terms of impact resistance?

- Aluminum sheets are renowned for their exceptional ability to withstand impacts. Their high strength-to-weight ratio ensures that they can endure significant forces without deformation or breakage, making them an optimal choice for industries like construction, automotive, and aerospace that require protection against impacts. The remarkable impact resistance of aluminum can be attributed to its inherent toughness. It possesses the capability to absorb and distribute energy from impacts, allowing it to withstand sudden forces and shocks. Moreover, aluminum's capacity to elastically deform enables it to absorb energy through bending and flexing, thereby minimizing the impact's impact on the material. Moreover, the impact resistance of aluminum sheets can be further enhanced through various techniques, including alloying and heat treatment. By alloying aluminum with elements like copper, manganese, or magnesium, its strength and impact resistance can be improved, resulting in a more robust alloy. Additionally, heat treatment processes like tempering or annealing can refine the microstructure of aluminum, thus enhancing its mechanical properties and impact resistance. In conclusion, aluminum sheets possess exceptional impact resistance due to their high strength-to-weight ratio, inherent toughness, and elastic deformability. Through advancements in alloying and heat treatment techniques, the impact resistance of aluminum sheets can be further enhanced to meet the specific requirements of diverse industries.

- Q: Are aluminum sheets suitable for architectural roofing?

- Yes, aluminum sheets are suitable for architectural roofing. Aluminum is a lightweight material that is resistant to corrosion, making it an ideal choice for roofing applications. It is also highly durable and can withstand harsh weather conditions, including extreme temperatures, UV radiation, and strong winds. Additionally, aluminum sheets are available in a variety of colors and finishes, allowing for flexibility in design and aesthetics. Moreover, aluminum is a sustainable and environmentally friendly material as it can be recycled indefinitely without losing its properties. Overall, aluminum sheets provide excellent performance and versatility, making them a popular choice for architectural roofing.

- Q: Are 101 aluminum sheets suitable for agricultural machinery?

- Indeed, agricultural machinery finds suitability in a total of 101 aluminum sheets. Aluminum, a material that is both versatile and lightweight, brings forth numerous advantages for agricultural machinery. Its outstanding resistance to corrosion becomes particularly vital for equipment that confronts diverse weather conditions and chemicals commonly encountered in the agricultural industry. Furthermore, the strength-to-weight ratio of aluminum proves to be advantageous, permitting an augmented payload capacity and enhanced fuel efficiency. Moreover, the malleability of aluminum allows manufacturers to fashion intricate shapes and designs for machinery components. All in all, the durability, corrosion resistance, and versatility demanded by agricultural machinery are adequately met by 101 aluminum sheets.

- Q: have been taking an over the counter Antacid consistently for the past 8 years as a daily source of extra calcium per the bottle. Now, I am getting many nerve problems, similar to Lou Gehrig's disease. I am a healthy 38 year old male who excersises, eats right and is generally health conscious. I am concerned that unknowingly I have toxified my body with the aluminum that apparently is in Antacid. I did not know this until now or of course I would not have gone any where near it.Can taking Antacid lead to nerve problems such as Lou Gehrig's disease?

- Aluminum okorder /

Send your message to us

PVDF and PE Color Coated Aluminum Lattice Sheets Coil Rolls

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords