PVC Waterproofing Membrane without Compound Layer

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

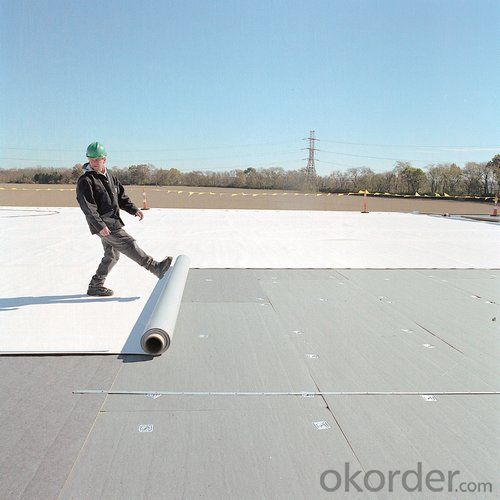

Polyvinyl Chloride (PVC) waterproof membrane is a new polymer waterproof membrane which is made from polyvinyl chloride resin, and mixed with plasticizer, filler, antioxygen, ultraviolet absorber and other auxiliaries.

Features

1) Excellent aging resistance. Service life of roofing material is over 20 years;

service life of underground material is over 50 years.

2) Root resistant penetration, specially used on planting roof.

3) Welding installation. Joints are solid and environment friendly, no pollution.

4) High tensile strength, good elongation and dimensional stability.

5) Good plasticity, easy and suitable for details installation.

6) Fireproof. Fire extinguished out of the ignition resource.

7) Surface is smooth, no fading and dirty resistant.

Specification

No. | Item | L | N | W | ||||

I | II | I | II | I | II | |||

1 | Tensile strength N/cm ≥ | 100 | 160 | 8 | 12 | 100 | 160 | |

2 | fracture elongation %≥ | 150 | 200 | 200 | 200 | 150 | 200 | |

3 | Dimension Changing at heating %≤ | 1.5 | 1 | 3 | 2 | 1.5 | 1 | |

4 | Foldability at low temperature °C | -20 | -25 | -20 | -25 | -20 | -25 | |

5 | Water tightness | No leakage | No leakage | No Leakage | ||||

6 | Joint shear resistance (N/mm)≥ | 3 | 3 | 6 | ||||

7 | Thermal Ageing treatment | Appearance | no bubble | no bubble | no bubble | |||

Tensile strength changing rate % | ±25 | ±20 | ±25 | ±20 | ±25 | ±20 | ||

Breaking elongation changing rate% | ||||||||

8 | Chemical corrosion resistance | foldability at low temperature °C | -15 | -20 | -15 | -20 | -15 | -20 |

Tensile strength changing rate % | ±25 | ±20 | ±25 | ±20 | ±25 | ±20 | ||

Breaking elongation changing rate% | ||||||||

9 | Artificial climate accelerated aging | foldability at low temperature °C | -15 | -20 | -15 | -20 | -15 | -25 |

Tensile strength changing rate % | ±25 | ±20 | ±25 | ±20 | ±25 | ±20 | ||

Breaking elongation changing rate% | ||||||||

Applications

1) All kinds of roofs, such as steel structure roof, planted roof etc.

2) Underground engineering, such as building basement, subways, tunnels, air raid shelter, etc.

3) Other projects like artificial lake, dam, water reservoir, grain storehouse, etc.

RFQ

1. What is your MOQ?

--Our MOQ is 5000 m2

2. Can you provide sample?

--Yes, samples are in stock. we can offer free sample for you.

3. Do you offer OEM service?

--Yes, we can print customers’ logo on the packaging;

And the size and specification can be produced and design according to your demand.

- Q: Can waterproofing membranes be used on foundation walls?

- Yes, waterproofing membranes can be used on foundation walls. Waterproofing membranes are specifically designed to prevent water infiltration and are commonly applied to foundation walls to protect them from moisture and water damage. These membranes are typically made of materials such as rubberized asphalt, thermoplastic, or PVC, which are durable and resistant to water penetration. They are installed on the exterior side of the foundation walls and provide an effective barrier against water, preventing it from seeping into the basement or crawl space. Waterproofing membranes are an essential component of building construction, as they help maintain the structural integrity of the foundation and prevent issues such as water damage, mold growth, and foundation settlement.

- Q: Can a waterproofing membrane be used for a commercial building?

- Indeed, a commercial building can utilize a waterproofing membrane. Specifically engineered to safeguard structures against water damage, these membranes find wide application in commercial settings, encompassing rooftops, basements, and foundation walls. Serving as a protective barrier, the membrane effectively prevents water infiltration, safeguarding against leaks, moisture accumulation, and the growth of mold. Moreover, waterproofing membranes exhibit durability, enabling them to withstand inclement weather conditions, rendering them suitable for commercial buildings exposed to heavy rainfall or extreme temperatures. Ultimately, the incorporation of a waterproofing membrane within a commercial building proves highly effective in preserving long-term structural integrity and averting costly water-related impairments.

- Q: Can a waterproofing membrane be used for tunnels and subway stations?

- Tunnels and subway stations can benefit greatly from the use of waterproofing membranes. These membranes are specifically designed to keep water and moisture out of structures, which makes them perfect for underground spaces like tunnels and subway stations that are prone to water infiltration. Made from high-quality materials like bitumen or synthetic polymers, these membranes have exceptional water-resistant properties. The advantages of using waterproofing membranes in tunnels and subway stations are numerous. First and foremost, they protect the structural integrity of the underground infrastructure by preventing water from seeping into the concrete or other building materials. This safeguards against corrosion and degradation, ensuring the longevity and safety of the structure. Additionally, waterproofing membranes contribute to a dry and comfortable environment within tunnels and subway stations. By preventing water accumulation, they eliminate the growth of mold, mildew, and other harmful microorganisms. They also help regulate humidity levels, which reduces the risk of condensation and water damage to equipment, electrical systems, and other components. Moreover, waterproofing membranes act as a barrier against external contaminants such as pollutants, chemicals, and gases. This is especially important in subway stations, where the concentration of pollutants from train exhaust and other sources can be higher. In conclusion, using waterproofing membranes in tunnels and subway stations is essential for ensuring the durability, safety, and comfort of these underground structures. They provide an effective solution for keeping water out, protecting the infrastructure, and maintaining a dry and healthy environment for passengers and staff.

- Q: Can a waterproofing membrane be used in areas with high groundwater levels?

- Yes, a waterproofing membrane can be used in areas with high groundwater levels. In fact, it is highly recommended to use a waterproofing membrane in such areas to protect the structure from water infiltration. A waterproofing membrane is specifically designed to create a barrier against water, preventing it from seeping into the building or structure. This can be particularly important in areas with high groundwater levels, as the pressure from the water can be significant and increase the risk of water damage or flooding. By installing a waterproofing membrane, you can effectively mitigate the risk of water infiltration and ensure the longevity and durability of the structure.

- Q: Can waterproofing membranes be used on outdoor patios?

- Yes, waterproofing membranes can be used on outdoor patios. They are an effective way to protect the patio from water damage and can help to prevent leaks and moisture penetration. Waterproofing membranes create a barrier between the patio surface and water, keeping it dry and extending its lifespan.

- Q: Can a waterproofing membrane be used on precast nickel surfaces?

- Yes, a waterproofing membrane can be used on precast nickel surfaces. Waterproofing membranes are designed to create a barrier against moisture and prevent water penetration. They can be applied to various surfaces, including concrete, metal, and even nickel. However, it is important to ensure that the waterproofing membrane is suitable for use on nickel surfaces and is compatible with the specific type of precast nickel being used. It is recommended to consult with a professional waterproofing contractor or the manufacturer of the membrane for guidance on the specific application and to ensure proper adhesion and effectiveness of the membrane on precast nickel surfaces.

- Q: Can waterproofing membranes be used on elevator shafts?

- Yes, waterproofing membranes can be used on elevator shafts. Elevator shafts are often subject to moisture, especially in areas with high humidity or underground installations. Waterproofing membranes are designed to provide a protective barrier against water and moisture, preventing them from seeping into the elevator shaft and causing damage to the structural components or electrical systems. These membranes are typically applied to the walls and floors of the shaft, creating a watertight seal that keeps the interior dry. Additionally, waterproofing membranes can also help to prevent the growth of mold and mildew, ensuring a safe and healthy environment for elevator passengers and maintenance personnel.

- Q: Are waterproofing membranes suitable for high-traffic areas?

- Yes, waterproofing membranes are suitable for high-traffic areas. These membranes are designed to provide excellent durability and resistance against heavy foot traffic. They create a protective barrier that prevents water from seeping through and damaging the underlying structure. Additionally, waterproofing membranes can withstand the wear and tear caused by constant use, making them an ideal choice for areas with high foot traffic such as commercial spaces, parking garages, or outdoor walkways.

- Q: Can a waterproofing membrane be used for highway or road projects?

- Highway or road projects can benefit from the utilization of a waterproofing membrane. These membranes are frequently employed in road construction to safeguard the underlying layers against water damage. Serving as a barrier, they effectively ward off water infiltration, thus averting the deterioration of the road structure. Application of these membranes is typically done on areas of high water exposure such as bridge decks, tunnels, and retaining walls. By preventing water from seeping into the road, the waterproofing membrane aids in prolonging its lifespan by mitigating moisture-related issues like cracks, potholes, and erosion. Furthermore, it enhances the road structure's durability and strength, bolstering its resistance against environmental elements. Ultimately, the integration of a waterproofing membrane in highway or road projects delivers long-term protection and ensures the endurance of the infrastructure.

- Q: Are there any drawbacks or limitations to using a waterproofing membrane?

- Using a waterproofing membrane comes with its fair share of drawbacks and limitations. One issue is the time-consuming and labor-intensive installation process. These membranes require careful surface preparation and multiple layers, which can be both time-consuming and require skilled labor. As a result, the overall cost of the project may increase. Another limitation is that not all surfaces are suitable for waterproofing membranes. Certain membranes are designed for specific types of substrates, such as concrete or metal, and may not adhere properly to other materials. To ensure proper adhesion and effectiveness, it is crucial to select the appropriate type of membrane for the specific surface. Moreover, waterproofing membranes can be sensitive to environmental conditions. Exposure to extreme temperature fluctuations, UV rays, and chemicals can degrade the membrane over time, reducing its effectiveness. To ensure the longevity of the membrane, regular inspections and maintenance may be necessary. Furthermore, during installation or due to external factors such as foot traffic or heavy objects, waterproofing membranes can be susceptible to damage. Punctures, tears, or improper installation can compromise the integrity of the membrane and reduce its ability to prevent water infiltration. Lastly, in certain situations, waterproofing membranes may not completely prevent water penetration. If there are existing cracks or structural issues in the substrate, water may find a way to seep through, bypassing the membrane. Therefore, it is important to address any underlying structural issues before applying the membrane to ensure optimal performance. In conclusion, while waterproofing membranes offer significant benefits in terms of water damage protection, it is crucial to consider these limitations and drawbacks before deciding to use them in specific applications.

Send your message to us

PVC Waterproofing Membrane without Compound Layer

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords