PVC Waterproof Membrane in 0.6mm Thickness and Low Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC Waterproof Membrane in 0.6mm Thickness

Product Description of PVC Waterproof Membrane in 0.6mm Thickness:

PVC Membrane Waterproof /Waterproofing membrane For Roof is a new polymer waterproof membrane. The PVC Membrane Waterproof /Waterproofing membrane For Roof raw material is polyvinyl chloride resin, mixed with plasticizer, filler, antioxygen, ultraviolet absorber and other auxiliaries.

Thickness: 1.2mm/1.5mm/1.8mm/2.0mm

Width:2050mm

Length:20m( Special specifications can be customized)

Size: 2.05mx20m

Color: white/grey, or any other colors.

Features of PVC Waterproof Membrane in 0.6mm Thickness:

1. Excellent aging resistance. Service life of roofing material is over 20 years; service life of underground material is over 50 years.

2. Root resistant penetration, specially used on planting roofings.

3. Welding installation. Joints are solid and environment friendly, no pollution.

4. High tensile strength, good elongation and dimensional stability.

5. Good plasticity, easy and suitable for details installation.

6. Fireproof. Fire extinguished out of the ignition resource.

7. Surface is smooth, no fading and dirty resistant.

8. Width is over 2m. Construction wastage is small, more economical.

Classification of PVC Waterproof Membrane in 0.6mm Thickness:

1. N: Homogeneous PVC membrane

2. L: PVC membrane with fabric backing

3. W: Reinforced PVC membrane

Advantage of PVC Waterproof Membrane in 0.6mm Thickness:

1.) Mixing automation. Apply automatic temperature control automatic time control and automatic feed control.

2.) Extrusion equipment uses twin screw coextrusion. Screw temperature uses computer automatic temperature control system.

3.) Handpiece uses large width didhead extrusion equipment.

4.) Sophisticated three-roller calender equipment. The space between equiment is controlled by automation system.

Technical Data of PVC Waterproof Membrane in 0.6mm Thickness:

No. | Item | Model Ⅱ | |

1 | Tensile Strength Mpa ≥ | 12.0 | |

2 | Elongation at break% ≥ | 250 | |

3 | Shrinkage rate % ≤ | 2.0 | |

4 | Flexibility at low temperature | No crackle at -25oC | |

5 | Water tightness | Watertight | |

6 | Puncture resistance | Watertight | |

7 | Heat aging treatment | Appearance | Free from bubble, crack, cohesion and void |

Change rate of tensile strength % | +20oC | ||

Change rate of elongation at break | |||

Flexibility at low temperature | No crack at -20oC | ||

8 | Chemical corrosion resistance | Change rate of tensile strength % | +20 |

Change rate of elongation at break | |||

Flexibility at low temperature | No crack at -20oC | ||

9 | Artificial weathering | Change rate of tensile strength % | +20 |

Change rate of elongation at break | |||

Flexibility at low temperature | No crack at -20oC | ||

Application of PVC Waterproof Membrane in 0.6mm Thickness:

PVC waterproof membrane forms an effective barrier to liquid water or water vapor in the steel structure for industrial and civil engineering, underground engineering, such as subway, bridges , tunnel, water pools, shelter, grain depot, land filling and subwayProducts display.

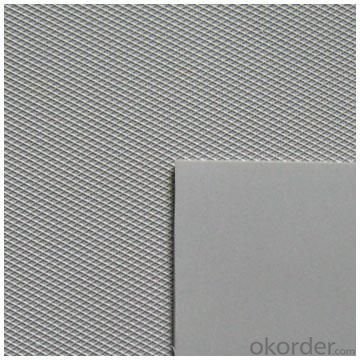

Images of PVC Waterproof Membrane in 0.6mm Thickness:

FAQ:

1. Can you produce 4m width?

Yes, no problem for us. We have four bases in China, largest one in this field.

2. How many quantity in one 20'' container for 1.2mm and 1.5mm?

480rolls, 11520m2 for 1.2mm and 400rolls, 9600m2 for 1.5mm

3. Can you provide free samples?

Yes, our samples are free, but express fees usually on buyer's account.

- Q: How does a waterproofing membrane handle water migration through the substrate?

- Water migration through the substrate is prevented by a waterproofing membrane, which acts as a barrier to inhibit water infiltration and structural damage. Typically applied on the exterior side of the substrate, the membrane establishes a watertight seal. To address water migration, the membrane is composed of flexible and durable materials like modified bitumen, PVC, or EPDM. These materials possess exceptional waterproofing properties and can endure exposure to water, UV rays, and other environmental factors. The membrane is installed to ensure proper adhesion to the substrate, creating a seamless and uninterrupted barrier. Multiple layers are often added to enhance its effectiveness, and the seams and joints are thoroughly sealed to prevent potential water leaks. Moreover, aside from its primary function of waterproofing, the membrane aids in managing surface water accumulation. It incorporates a slope or drainage system that redirects water away from critical areas and towards suitable outlets or drains. In summary, a waterproofing membrane is specifically engineered to manage water migration through the substrate by establishing a reliable and long-lasting moisture barrier. It plays a crucial role in safeguarding structures against water damage, ensuring their durability and longevity.

- Q: Are there any environmental considerations when using a waterproofing membrane?

- Yes, there are several environmental considerations when using a waterproofing membrane. One of the main concerns is the potential for harmful chemicals or materials to be used in the production of the membrane. Some waterproofing membranes may contain toxic substances such as volatile organic compounds (VOCs) or heavy metals, which can have detrimental effects on human health and the environment. Another consideration is the disposal of the membrane once it reaches the end of its life cycle. Many waterproofing membranes are not biodegradable and can contribute to landfill waste. Improper disposal can lead to environmental pollution and harm to ecosystems. Additionally, the production of waterproofing membranes often requires energy-intensive processes and the extraction of non-renewable resources. This can contribute to greenhouse gas emissions and the depletion of natural resources. To mitigate these environmental concerns, it is important to choose waterproofing membranes that have been manufactured using eco-friendly materials and processes. Look for products that are labeled as low VOC or free from hazardous substances. Additionally, consider using membranes that are recyclable or made from recycled materials to reduce waste generation. Proper disposal of the membrane at the end of its life cycle is also crucial, and options such as recycling or repurposing should be explored. Overall, it is essential to consider the environmental impact of waterproofing membranes and choose products and practices that minimize harm to the environment and promote sustainability.

- Q: Can a waterproofing membrane be used for roofs with foot traffic?

- Yes, a waterproofing membrane can be used for roofs with foot traffic. However, it is important to choose a membrane that is specifically designed and rated for foot traffic. These membranes are typically made with more durable materials, such as reinforced PVC or modified bitumen, to withstand the wear and tear caused by regular foot traffic. Additionally, it is crucial to ensure that the membrane is properly installed and maintained to prevent any damage or leaks that could compromise the waterproofing capability. Regular inspections and necessary repairs should be carried out to ensure the longevity and effectiveness of the membrane.

- Q: Can waterproofing membranes be used on wood surfaces?

- Yes, waterproofing membranes can be used on wood surfaces. Waterproofing membranes are versatile products that can be applied to a variety of materials, including wood. They are designed to create a protective barrier that prevents water from penetrating the surface, thereby preventing damage caused by moisture, such as rotting, warping, or mold growth. When applied correctly, waterproofing membranes can effectively seal wood surfaces, making them resistant to water absorption and increasing their durability and lifespan. It is important to choose a waterproofing membrane that is specifically formulated for wood applications and follow the manufacturer's instructions for proper application and maintenance.

- Q: Can a waterproofing membrane be used on metal block surfaces?

- Yes, a waterproofing membrane can be used on metal block surfaces. Waterproofing membranes are designed to create a barrier against water and moisture, and they can be applied to a variety of surfaces, including metal. The membrane will adhere to the metal surface, creating a waterproof layer that helps prevent water infiltration and protect the metal from rusting or corrosion. However, it is important to ensure that the metal surface is clean, dry, and properly prepared before applying the waterproofing membrane to ensure proper adhesion and effectiveness. Additionally, it is recommended to consult with a professional or refer to the manufacturer's instructions for specific guidance on using a waterproofing membrane on metal block surfaces.

- Q: Does a waterproofing membrane require any specific preparation of the substrate before installation?

- Yes, a waterproofing membrane typically requires specific preparation of the substrate before installation. The substrate, which is the surface on which the membrane will be applied, needs to be clean, dry, and free from any contaminants or debris that could hinder the adhesion of the membrane. This usually involves removing any loose materials, such as old paint or sealants, and smoothing out any uneven surfaces. Additionally, it may be necessary to repair any cracks or damage in the substrate to ensure a proper and effective installation of the waterproofing membrane. Following the recommended preparation procedures will help to maximize the performance and durability of the membrane, ensuring its effectiveness in preventing water penetration and protecting the underlying structure.

- Q: Can waterproofing membranes be used on concrete dams?

- Concrete dams can indeed benefit from the application of waterproofing membranes. In fact, they are widely utilized in the construction and upkeep of such dams to prevent water from leaking or seeping through. The purpose of these membranes is to establish a water-resistant barrier, safeguarding the concrete surface of the dam against potential water-induced harm. Notably, these membranes can be administered to both the interior and exterior facets of the dam, presenting a reliable and enduring solution for waterproofing. Moreover, they can effectively lessen the likelihood of water-related deterioration, including freeze-thaw damage and reinforcement corrosion, thus prolonging the lifespan of the concrete dam.

- Q: Can a waterproofing membrane be used for a balcony deck?

- Yes, a waterproofing membrane can be used for a balcony deck. Waterproofing membranes are specially designed to create a barrier against water penetration, which is essential for protecting structures such as balcony decks from moisture damage.

- Q: Are there any specific tools or equipment required for installing a waterproofing membrane?

- Yes, there are specific tools and equipment required for installing a waterproofing membrane. Some common tools include a trowel, utility knife, paint roller, brush, and caulking gun. Additionally, a heat gun or torch may be needed for certain types of membranes that require heat activation. It is important to follow the manufacturer's instructions and recommendations for the specific membrane being installed to ensure proper installation and effectiveness.

- Q: Is a waterproofing membrane environmentally friendly?

- Yes, a waterproofing membrane can be considered environmentally friendly. Waterproofing membranes are designed to prevent water leakage and damage to structures, which can contribute to the longevity of a building and reduce the need for repairs or replacements. This can result in a reduction in construction waste and the overall environmental impact of the building industry. Furthermore, some waterproofing membranes are made from eco-friendly materials, such as recycled content or bio-based materials, which can help reduce the carbon footprint associated with their production. Additionally, these membranes can be designed to be recyclable or biodegradable, further reducing their environmental impact at the end of their life cycle. Moreover, by preventing water infiltration, waterproofing membranes can help protect the structural integrity of buildings, preventing moisture-related issues such as mold growth and rot. This can contribute to maintaining a healthy indoor environment and reducing the need for energy-intensive remediation measures. It is important, however, to consider the specific characteristics and certifications of a waterproofing membrane to assess its environmental friendliness accurately. Look for certifications such as LEED (Leadership in Energy and Environmental Design) or products that have undergone life cycle assessments to ensure that they meet rigorous environmental standards. In summary, while not all waterproofing membranes may be inherently environmentally friendly, the use of certain materials and the prevention of water damage can make them a sustainable choice for building projects.

Send your message to us

PVC Waterproof Membrane in 0.6mm Thickness and Low Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords